Thanks for all the pictures, it makes for a very lively story. Interesting tip on how to preserve the steel of the horseshoes, I will definitely remember that; not as if it were possible to do galvanizing all the time with all the tools handy.

Apparently, depending on how high the temperature is, it will greatly influence the color of it

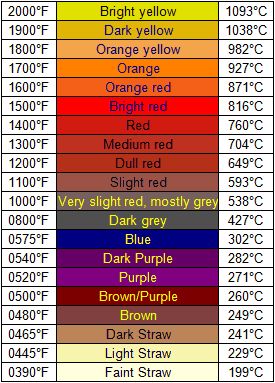

At high temperatures, steel takes on colors ranging from dull red to bright yellow, while at low temperatures it changes into colors such as brown, purple, blue and grey.

- Prepare an appropriate heat source, such as a charcoal fire, a propane forge, a torch, high temperature salt bath or electric furnace. Ideally, the heat source will provide a uniform heat, be easily controlled and provide a non oxidizing environment.

Heat the steel to temperatures from 400 to 800 degrees Fahrenheit, to produce oxidation colors. At 480 degrees F., the steel turns brown, at 520 degrees, it turns purple, at 575 degrees, it turns blue and at 800 degrees, it turns grey. These temperatures are commonly used in tempering tool steel.

Heat the steel above 800 degrees to produce incandescent colors. From 1000 to 1500 degrees, the steel will turn an increasingly brighter shade of red. At the critical eutectoid temperature of 1335 degrees, the steel recrystallizes as austenite and eventually loses its magnetic charge. From 1600 to1900 degrees, the steel will turn orange and then yellow. At 2000 degrees, the steel will be bright yellow.

Remove your steel from the heat source and quench it vertically in oil. Once the steel is cool enough to handle, temper it as soon as possible.