- Joined

- Jun 24, 2014

- Messages

- 316

- Reaction score

- 837

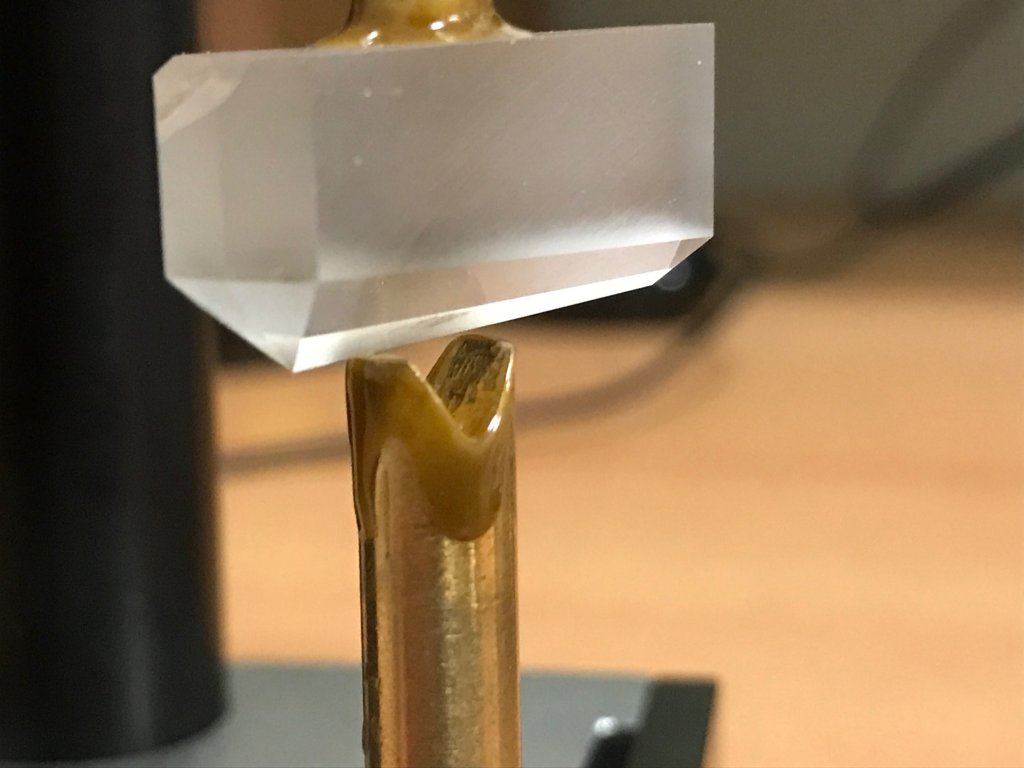

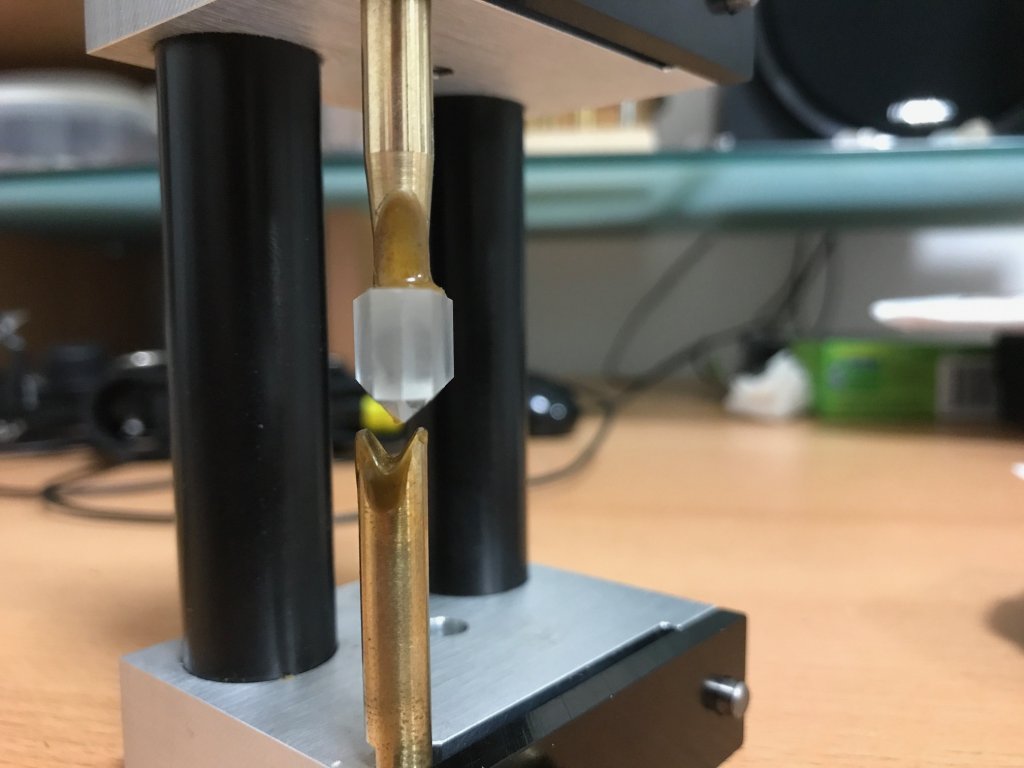

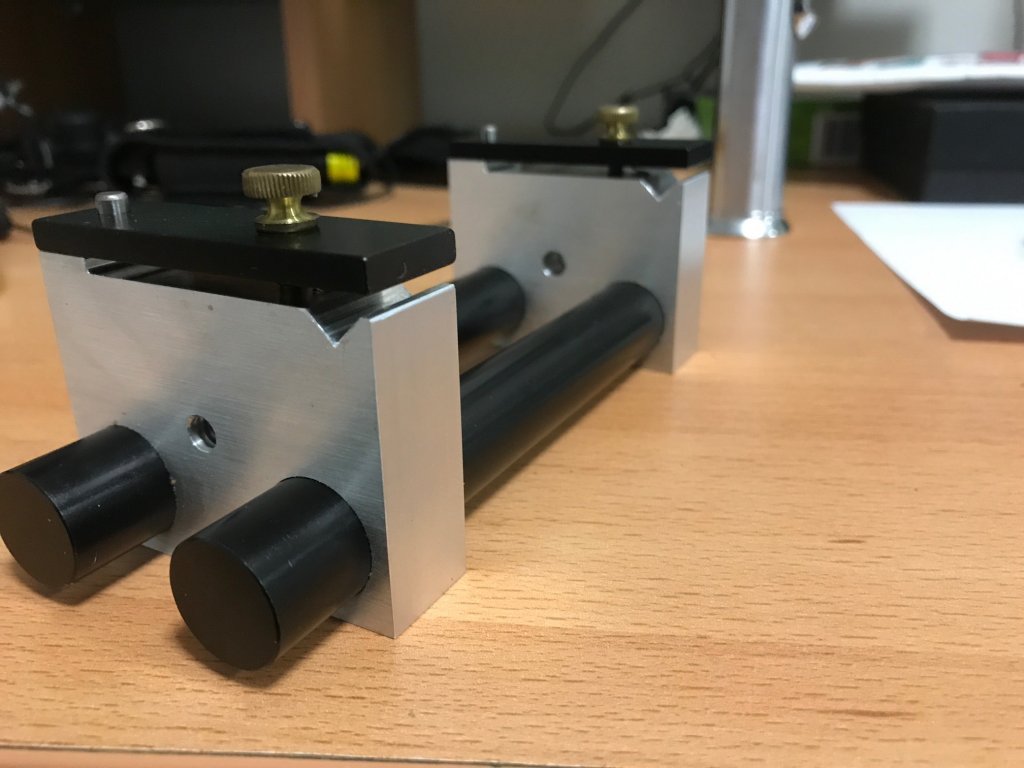

Really enjoying this new cut. Its so easy to do and has a great effect. Bit hard to photograph but this is the best I can do. Have to do it under low artificial light as outdoors the brilliance is to high to capture the image.