Moneybox

Philip & Sandra Box

I consider myself pretty good at most tasks. Theres not too much that I try to do where I fail but my attempt at melting our little scraps of SDC gold into an ingot was not very successful.

I started out with an old stainless steel electric kettle. I removed the lid and all the electrical components.

Then I went to Bunnings and bought a bag of Perlite potting mix. Perlite is a lightweight mineral that is crushed into about 5mm particles. Its a good heat insulation and can handle the temperatures required for a gold furnace.

The perlite is bonded with Silica Glass, a liquid that you can manufacture but I preferred to buy it online in powder form.

I made a little wooden plug the shape I wanted my ingot to end up and then used it to form the cement mould. I formed the mould in a steel shell so that even if it cracked the gold couldnt easily escape.

I decided to buy the oxy & acetylene from Bunnings because they dont charge a rental fee on the bottles. Then I found out that it was going to cost me over $500 for the deposit and gas so I looked for other ways. I connected the LPG to the cutting torch but just supplied compressed air to the oxy hose.

For the first trial run I used a couple of small lead wheel weights with a pinch of borax for flux. This ingot is just lead but I got to try the equipment.

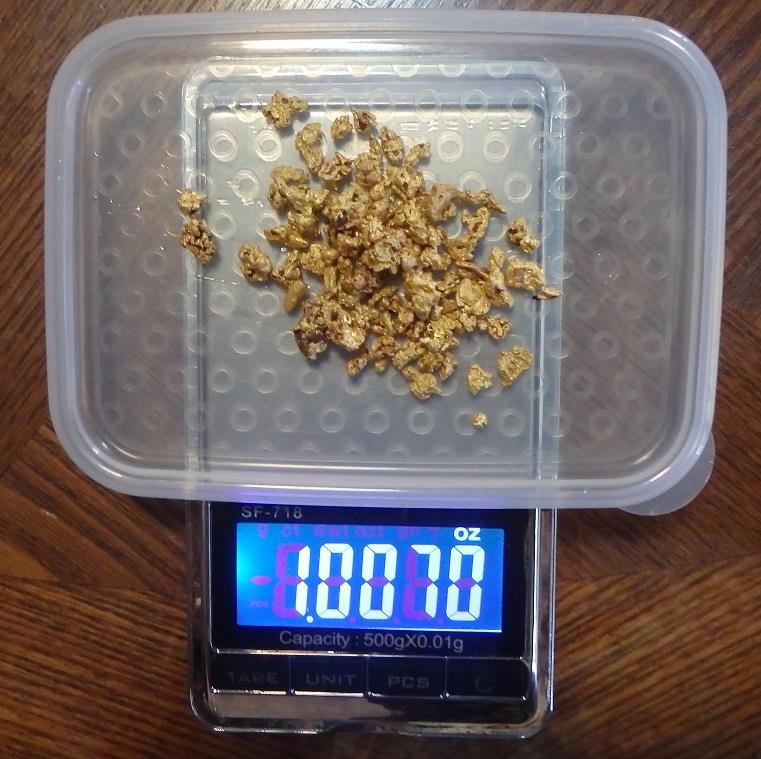

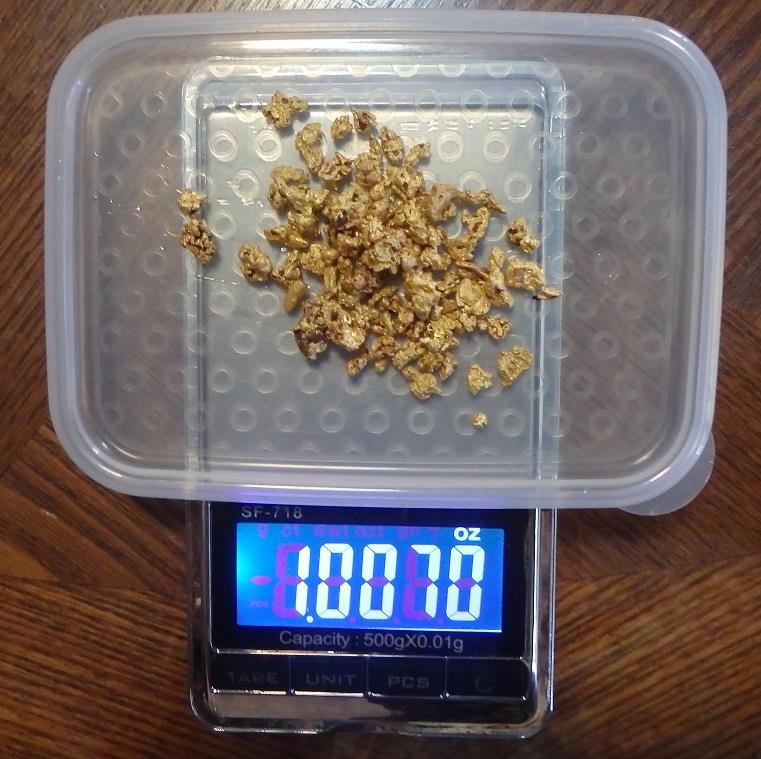

For a real pour I started with just over an ounce of clean gold.

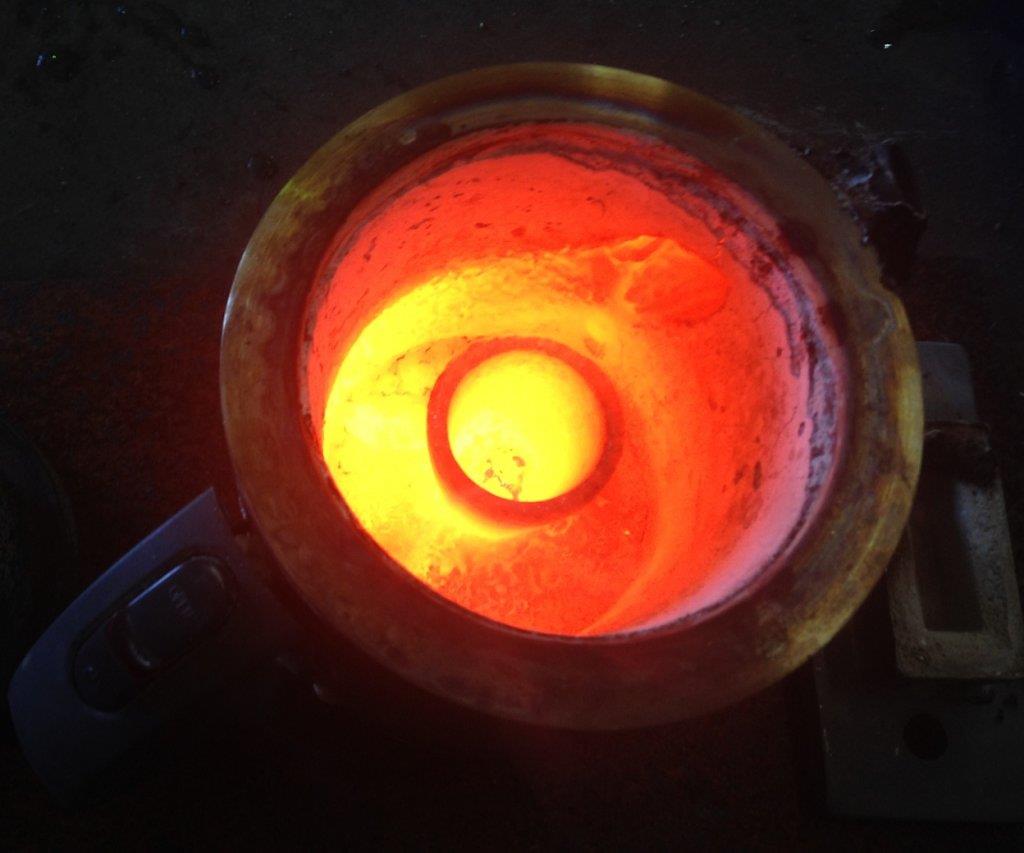

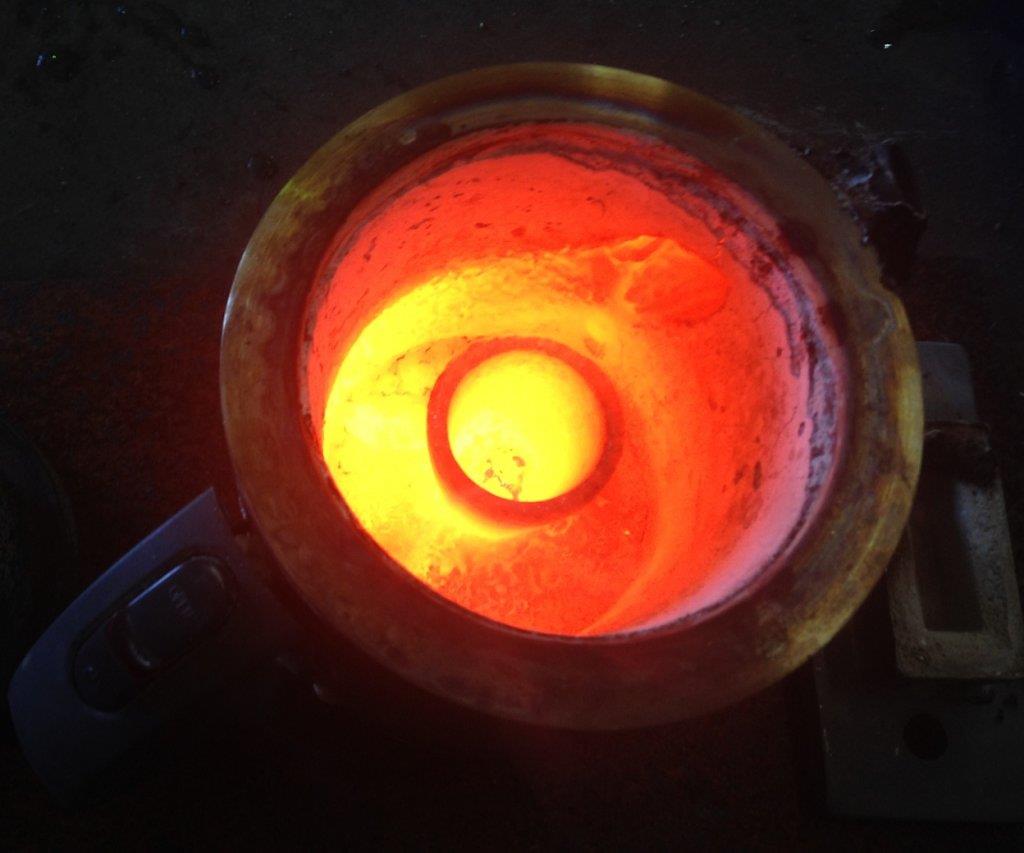

As you can see the flame was intense and the sound of the furnace in action was deafening.

This photo is after the flame has been turned off. The crucible and gold were glowing almost white but it was still not hot enough to melt the gold.

I ended up driving to Busselton where I could use my brothers oxy/acetylene torch to melt it.

The first pour went well but the borax I used for flux stayed firmly stuck to the crucible. I loaded the second one ounce batch with a little more borax and it soon became a molten mass that appeared transparent. I figured it might be a bit too hot to pour so I gave it a few moments to cool but that was a mistake. I don't know what caused the problem but the gold and flux solidified and wouldn't pour. Even when a lot more heat was applied it stayed solid to touch with a screwdriver.

Eventually it melted again so I parted the flux with a screwdriver and poured it. The resulting ingot came out looking more like copper than gold.

Some gold stayed in the crucible, some coated the screwdriver and perhaps there's still some in the flux.

Overall I'm not happy with my efforts so far.

My furnace was not hot enough. My second piece of gold came out looking more like copper. I lost (for now) a lot of gold in the process and messed up the crucible I'll just have to give it another go.....

I'll just have to give it another go.....

I started out with an old stainless steel electric kettle. I removed the lid and all the electrical components.

Then I went to Bunnings and bought a bag of Perlite potting mix. Perlite is a lightweight mineral that is crushed into about 5mm particles. Its a good heat insulation and can handle the temperatures required for a gold furnace.

The perlite is bonded with Silica Glass, a liquid that you can manufacture but I preferred to buy it online in powder form.

I made a little wooden plug the shape I wanted my ingot to end up and then used it to form the cement mould. I formed the mould in a steel shell so that even if it cracked the gold couldnt easily escape.

I decided to buy the oxy & acetylene from Bunnings because they dont charge a rental fee on the bottles. Then I found out that it was going to cost me over $500 for the deposit and gas so I looked for other ways. I connected the LPG to the cutting torch but just supplied compressed air to the oxy hose.

For the first trial run I used a couple of small lead wheel weights with a pinch of borax for flux. This ingot is just lead but I got to try the equipment.

For a real pour I started with just over an ounce of clean gold.

As you can see the flame was intense and the sound of the furnace in action was deafening.

This photo is after the flame has been turned off. The crucible and gold were glowing almost white but it was still not hot enough to melt the gold.

I ended up driving to Busselton where I could use my brothers oxy/acetylene torch to melt it.

The first pour went well but the borax I used for flux stayed firmly stuck to the crucible. I loaded the second one ounce batch with a little more borax and it soon became a molten mass that appeared transparent. I figured it might be a bit too hot to pour so I gave it a few moments to cool but that was a mistake. I don't know what caused the problem but the gold and flux solidified and wouldn't pour. Even when a lot more heat was applied it stayed solid to touch with a screwdriver.

Eventually it melted again so I parted the flux with a screwdriver and poured it. The resulting ingot came out looking more like copper than gold.

Some gold stayed in the crucible, some coated the screwdriver and perhaps there's still some in the flux.

Overall I'm not happy with my efforts so far.

My furnace was not hot enough. My second piece of gold came out looking more like copper. I lost (for now) a lot of gold in the process and messed up the crucible