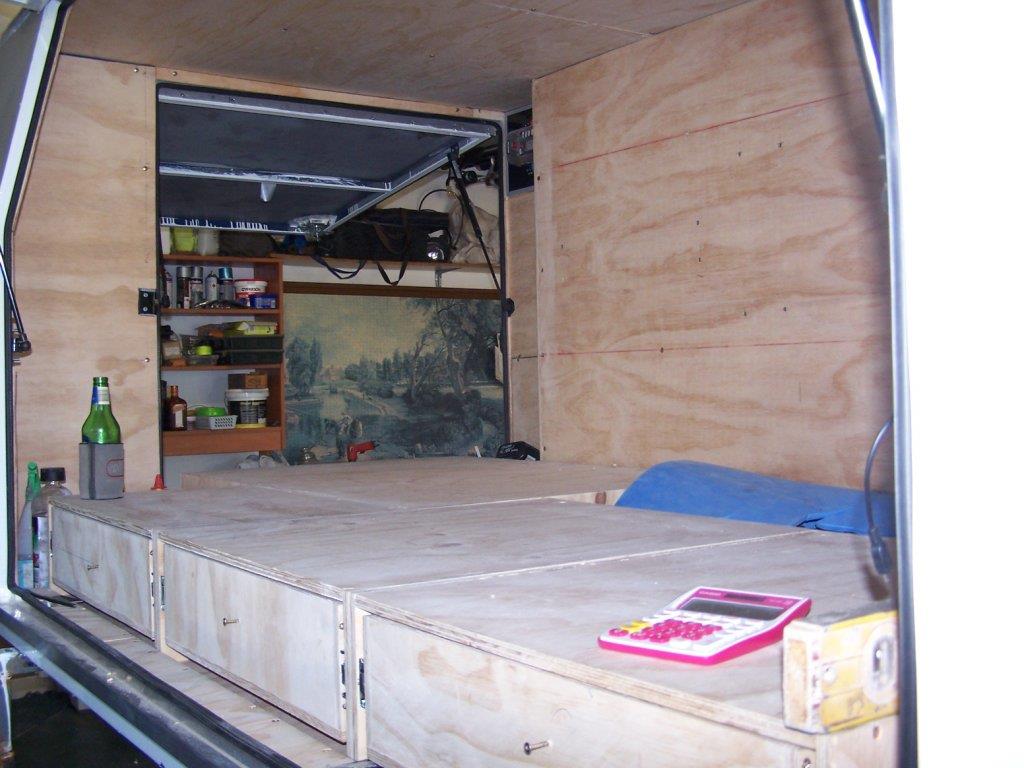

As the canopy sat on the tray of the ute I was concerned about dust and moisture coming up inside from between the tray and the floor. If you go back to the first frame pics you will see I framed out sufficiently to lay ply down as a weather proofing. I had a friendly neighbor who worked in the construction industry and he scored me 2 sheets of used 18mm form ply. This stuff has a black waterproof coating so most of the work was already done for me. He advised me to paint the edges with coldgal paint as this soaks in and waterproofs the layers of ply. Any gaps, old screw holes, joins after I scribed(cut to shape) the sheets and screwed them down were filled with a generous application of silicon.I didn't have to fussy with the silicon finish as the whole floor would be hidden by the drawers. I will concede that all the ply added to quite a bit overall weigh (18kg)I felt that for the cost I couldn't complain. Think of the cost of doing it in aluminum at $40sqm over 3.6 sq m speaks for itself.

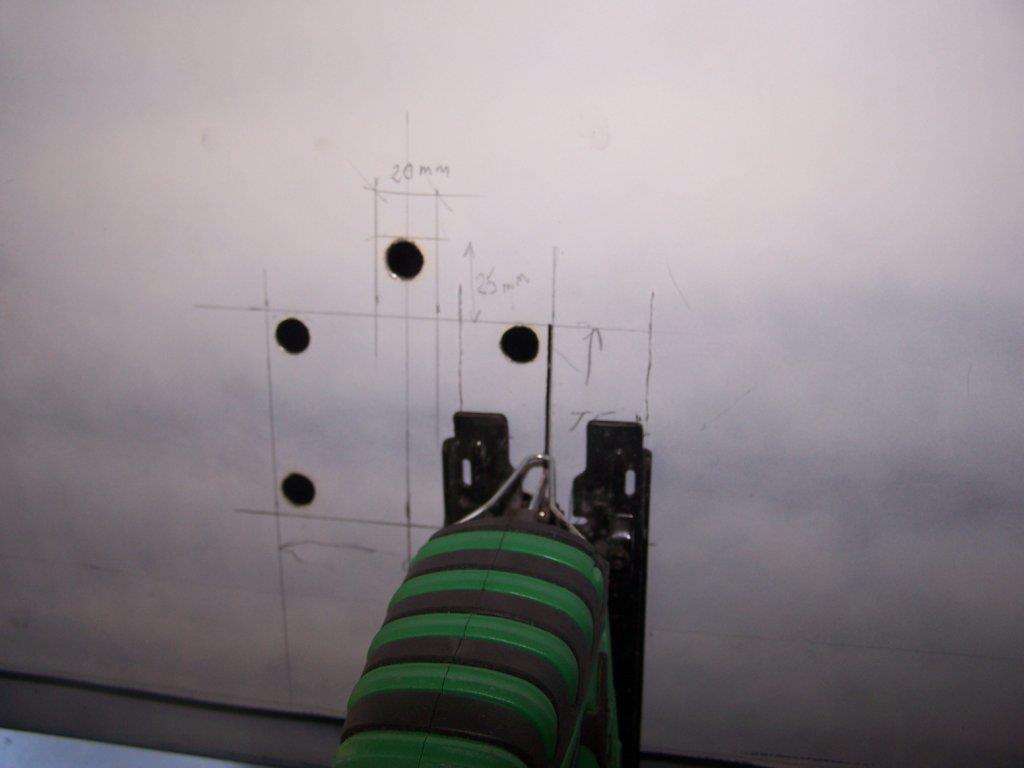

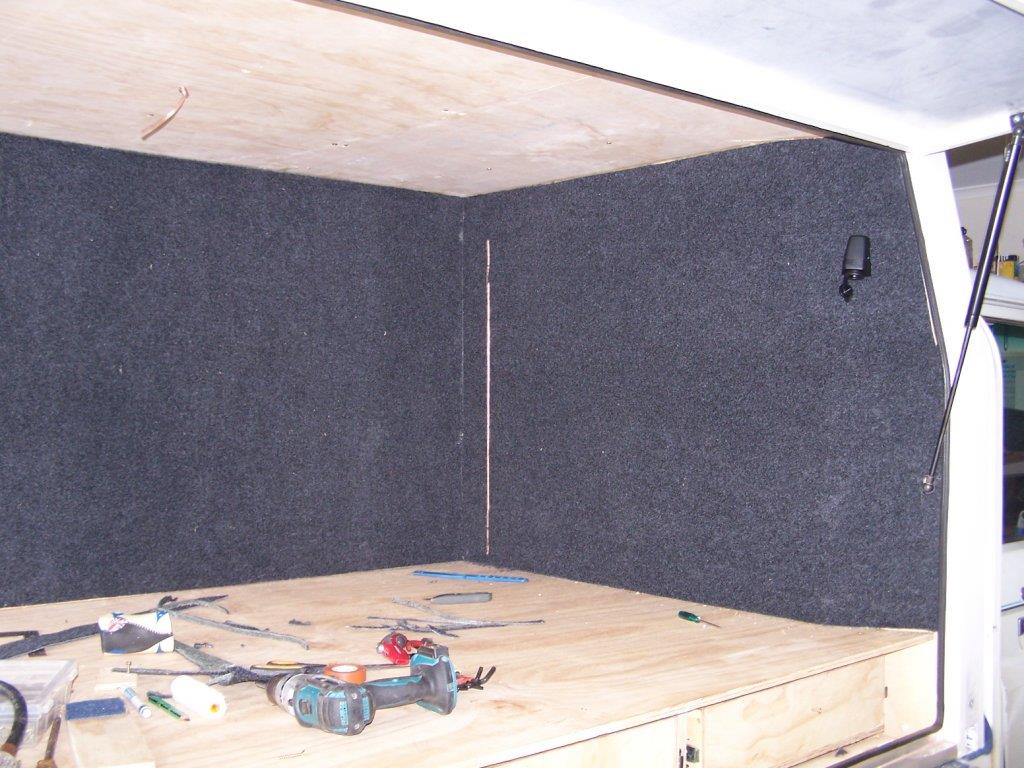

The main walls were made from 9mm construction ply and cost around $36 sheet and I used approx 6 8x4 sheets. Seems a lot but there is a false wall right across the front, as well as all the fiddly bits around and inside the gas and electrical areas and the ceiling. One point to remember is if you are fixing with self tapping pan or wafer head screws through thick steel frames(mine were2mm) buy the fine thread variety, as I had a box of coarse threaded ones and they either snapped off before they screwed right home or the cross head chewed out, not a thing you want to happen when putting screws in awkward spots or overhead.When I was scribing in the ply around an area where the carpet had to be cut neat to a finish as around the door frame with the inner seal installed, I had to allow at least 10mm for the thickness of the carpet.I chiseled out a groove for the bed light wire and slid a 10mm plastic tube over it as it was pushed up between the steel frame and the ply. Just a precaution to stop it wearing through and causing a short.

The false wall depth was determined by the depth of the satellite dish in the folded position(Access Antennas and Satellites from WA)200mm.I put ply on the frame them made packers or spacers and then the false wall ply. This inner ply gave me something to attach anything else at a later date.These packers can be seen in the previous prewire pics.

If I had misaligned a sheet at a corner I gave it a sand down with a belt sander to make it flush.

Because the frame was just that, a frame, I had not allowed for the sheets to be attached at the intersections of the walls and ceiling so I had to scribe around the ribs so I could screw them on. Bit of a pain and in hind sight a few tabs in the right places would have saved me heaps of time and effort.

The water tank sat in its own recess to stop movement, wrapped in high density foam rubber for further protection and then I built around it with the drawer carcasses which cocooned it snugly in place.

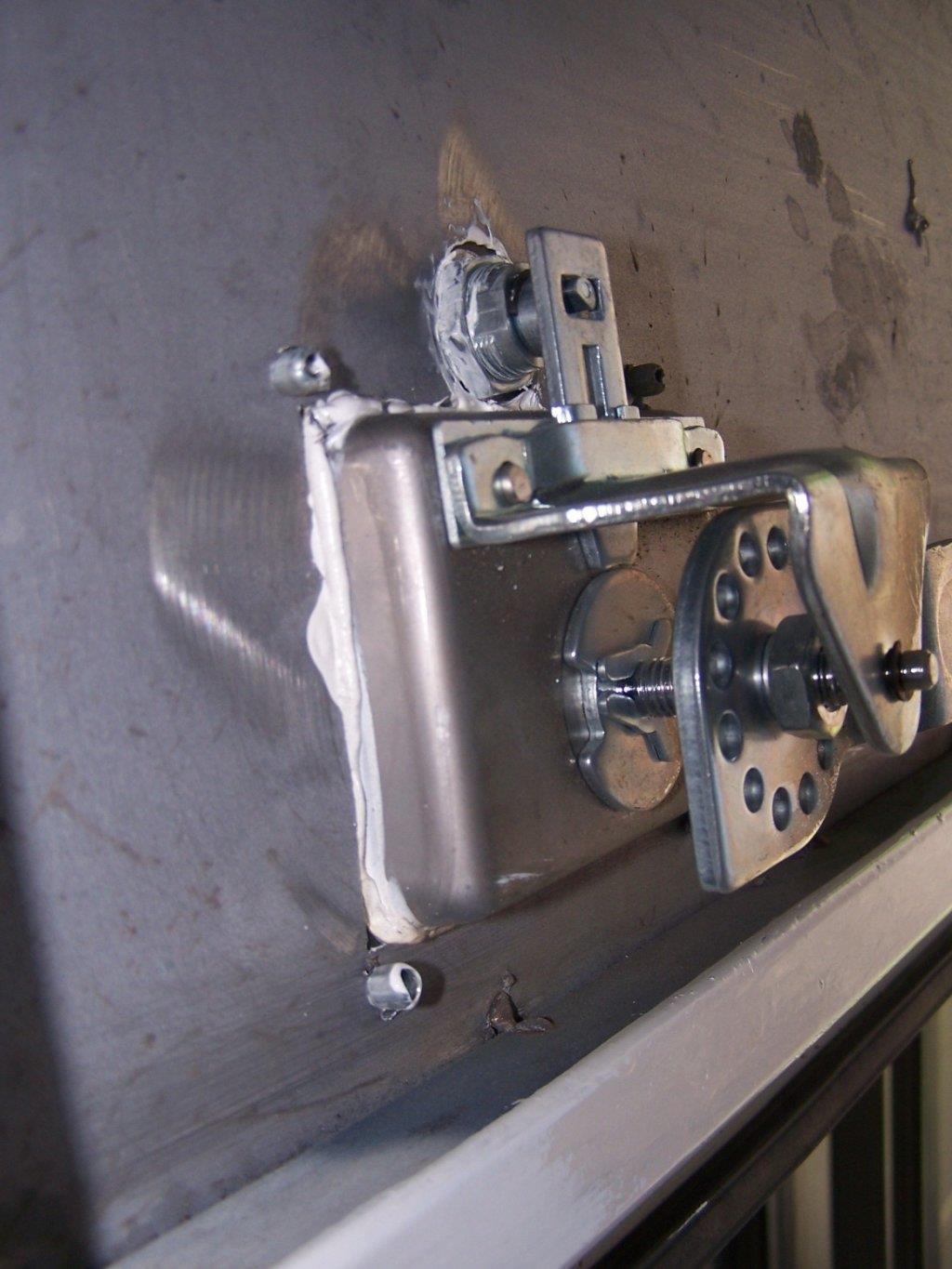

I did buy and install the struts for all the doors(ouch that hurt the pocket!) but all I had to do was weigh the door on the hinge, take the measurements and take all this info into the local gas strut shop and they worked out the NM for pressure and also the measurements where on the main frame and how far out on the door they should be attached.

To measure the door weight you simply open it to the position you want it to go to,and with a set of bathroom scales on the floor, prop up the door with a piece of wood or similar on the scales. What it reads is the down weight of the door and that determines the NM of pressure in the struts.

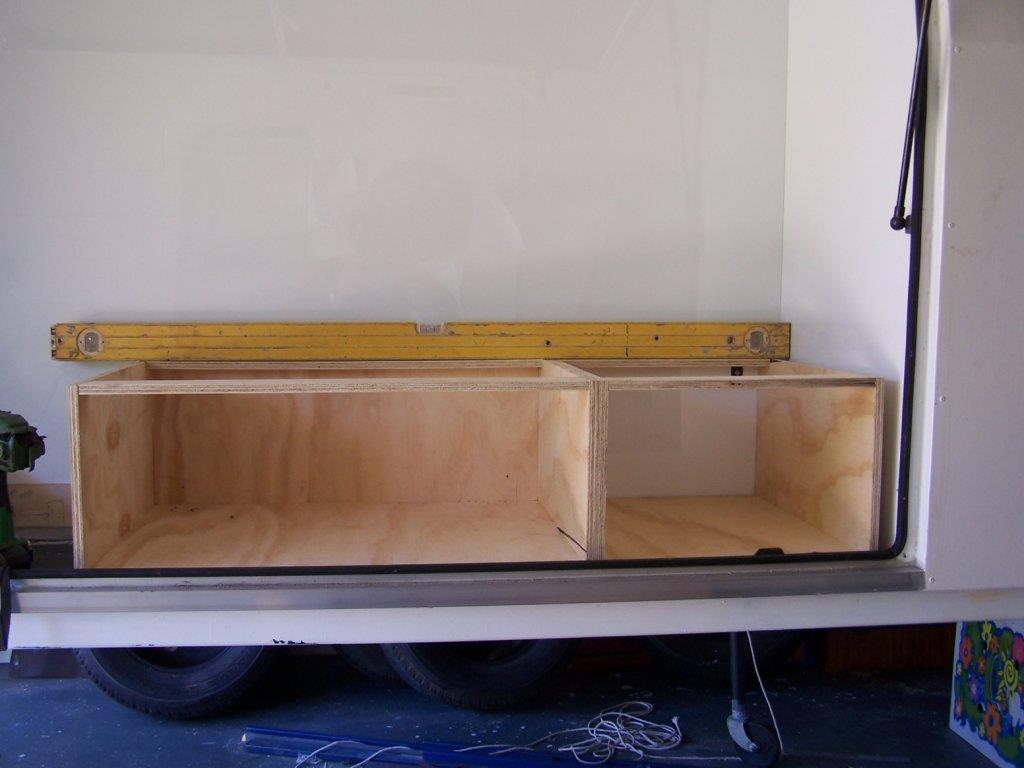

Next, drawers