- Joined

- May 26, 2018

- Messages

- 385

- Reaction score

- 1,145

Looks the ducks guts, great job, now we want to

see what you can do. :gemstone:

see what you can do. :gemstone:

Dihusky said:Rotational direction shouldn't make any difference, provided the fixing nut is threaded the correct way so it doesn't come undone when you start the motor. Anti-clockwise needs a right hand thread, clockwise needs a left hand thread, looking from the lap end of the shaft. You just work on the side that pushes into the stone.

A master will depend on the laps you're using. The thin topper laps all need a backing plate, often with a magnetic topper glued to it so it grips the lap.

Felt, rubber, acrylic for polishing will all need a backing master, different from the magnetic one, felt and rubber are normally permanently bonded to a backing plate. Acrylic, it's purely for support against stone/hand pressure.

This mob: https://www.gemworld.com.au/products/show/348/polishing-laps used to have backing plates with a screwed boss in either LH of RH threads, I have some of them which I purchased from them, think they might have been custom made, so could be worth giving them a call, otherwise contact people like Gemcuts for threaded backing plates.

xcvator said:I need a lot more help on how to mark out cabs, not just the shape but the girdles and forming the domes.Any tricks to learn ?

What are the best stones to learn on, I've got some bits of Rhodonite (good to work with) Sodalite ( like the colour) Labradorite ( love the colour, fractures along lines easily) Rose Quartz (looks good untill it's polished, then it looks insipid (to me, a nothing washed out stone)

Noticed that the "superglue" can penetrate and remove some material where it's been holding the dop (lepodolite, must be a bit porous )

Does the wax/shellac combination ever damage the surface of cabs?

Have you watched any of Justins youtube vids, he explains in several about all the stuff you are after, thats how I taught myself, have watched every vid several times. Black Opal Direct is the youtube channel from memory.xcvator said:Thanks Wally :Y: :Y:

LoneWolf said:Xcvator, You can just change the blade over to a thin lapidary blade but make sure it has the same size bore (the hole in the middle)...

If you are worried about the gap around the blade, just get a piece of very thin Aluminium and cut a slit halfway along it and slip it around your blade...

LW...

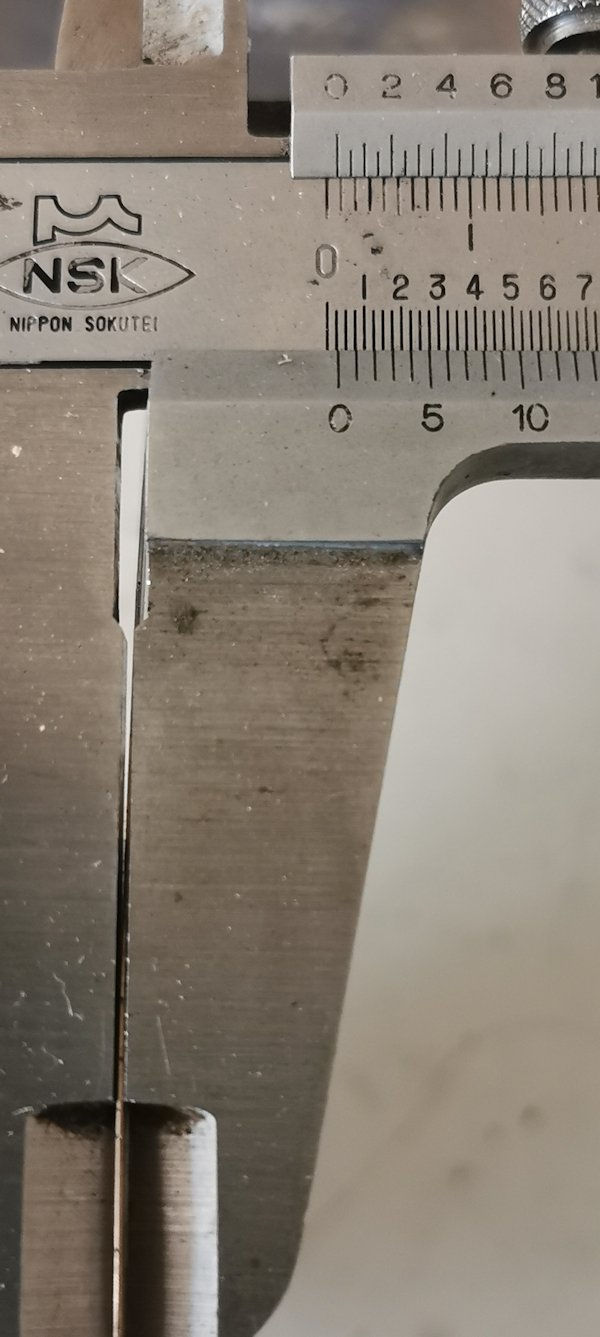

sand surfer said:what size is the arbor of the saw xcvator, i have thick(slabbing) and a thin blade for a 7" saw if they fit you can have them ,i don't have the saw anymore and the arbor on my new saw is a different size so they don't fit,the bore on the blades are 5/8"(about 16 mm)

xcvator said:Has anybody built their own 8"trim saw, I've got the little tile saw that 2lateagain sent me, cuts well, but the blade is quite thick and tends to shatter/chip some of the rocks so I'd like to get/make a trim saw with a very fine blade, that would make the final shaping much easier

LoneWolf said:Wow that seems to be a large bore... I think mine is only 16mm.. I will measure it tomorrow...

But no those blades wont work, I think they will chip your stone pretty easily... but I haven't tried that type...

My tile saw takes 7" blades but I can use a 8" I think... there's enough room there for it...

Is there room under (no)... as you can always cut the slot in the saw a bit longer to take the larger blade.. It has been done on mine..

Have you looked on Aussie Sapphire or Gemcuts website?

I found some for you but only a 20mm bore (gem-cuts on ebay)... think you might need to convert with bushings from 22mm down (Not possible to bush down in size) to imperial or metric to do what you want...

https://www.ebay.com.au/itm/5-Thin-...726641?hash=item23b7b19fb1:g:tNEAAOSwSnZe6lG6

LW...

Dihusky said:xcvator said:Has anybody built their own 8"trim saw, I've got the little tile saw that 2lateagain sent me, cuts well, but the blade is quite thick and tends to shatter/chip some of the rocks so I'd like to get/make a trim saw with a very fine blade, that would make the final shaping much easier

Tile blades are totally wrong for what you're doing, too thick and slow. You can get diamond blades that are a lot thinner, they come in two types; sintered and plated, the one to go for is sintered as they last a very long time in comparison to the plated blades.

We have a tile saw currently and use a 0.5mm thick sintered blade, cuts like a hot knife through butter and easy to control the stone.

One thing to remember is diamond cuts at the rate it wants to cut, forcing a blade to cut will only damage the blade, the stone and possibly yourself, cutting is a job of patients not rush.

Enter your email address to join: