Meta's questions,

1: Both mate, by backfilling stopes with waste we kill a few birds with one stone, firstly, cost cutting on the transport of waste to the surface, secondly, minimises the wear and tear on our haulage gear, thirdly, we can support the 'open stope' to take our next 'panel' or round and for general ground support.

Allow me to elaborate a wee bit before I continue, we are still talking small scale here, by this I'm talking drives that are roughly 1.8meters wide, by 2.8meters high, the norm for stopes is anywhere between 4-6 meters (plus) depending on your ground integrity, and the type of equipment being run.

You can run smaller drives and minimise your waste from around your ore, in this case you would most likely be using a little dingo or toro digga to bog your dirt, or maybe even a wheel barrow.

There are a few things to be aware of when tipping waste back down stope, make sure it's waste, there is such a thing as secondary enrichments, scattered minerals outside of the main ore body, gold, tin, lead, copper, whatever, this is not visible to the human eye, for small scalers, or water processors, anything we can't see is waste, that very well may not be the fact, biox processing mines extract dirt as little as 4grams to the tonne, with chemicals they can leach gold so fine we cannot see it, your waste from around the ore body, might actually be running from 2-20 grams to the tonne, but if we can't see it, it's waste, strike a deal up with a larger mining company that can process mineralised gold, you could very well find yourself selling what you would assume to be waste, for a substantial amount per tonne, that amount could quite easily cover costs, and see everything else as pure fat on top

And for the safety side, before tipping waste down an open stope, a bund wall needs to be installed before you can even attempt to backfill, this wall needs to be 3/4 the height of the tyres on whatever machine you are operating, I've heard quite a few stories of loaders going over into open stopes simply because they forgot to install a two to three bucket wall, and if your wheel barrowing or bucketing, I would suggest a harness and lanyard, 3 meters might'nt sound far but it is in the dark landing on jagged rocks!

Right back on track

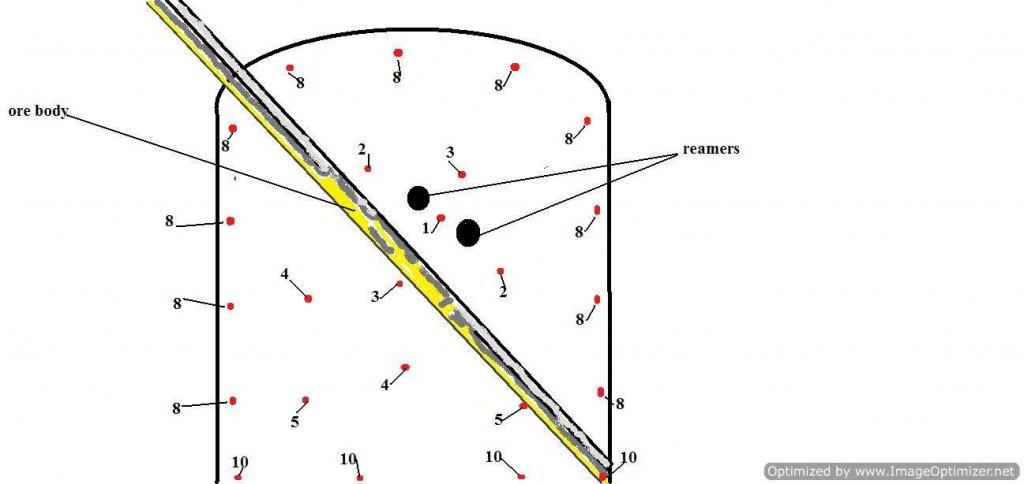

I think I can answer the rest of your questions combining them all together, for sinking your shaft, honestly you would want to pick the best ground, so in saying this, the face of your non gold bearing rock heads down and joins with the lower edge of your reef, this is referred to as the 'footwall', opposite that on the other side of the reef is called the hanging wall, rule of thumb, sink your shaft in the 'footwall' and waste, steer clear of the 'hanging wall' and ore body, ordinarily I would sink quite a few meters away from the ore body, ensuring that I was placing my shaft in good ground, but, in the case of working a tight budget and we can only afford to break pay dirt, then I would sink directly on top of the gold bearing reef, keep in mind though, if you do sink directly on top of your ore body, you have just destroyed your chances of mining whatever gold may be sitting out in that ore body within 5-6 meters of your shaft the whole way down.

Also good to keep in mind is where your going to sink your second shaft for return airway and secondary means of egress.

"Does the waste come from cutting in a drive to the reef"

Yes and no, your first initial waste dirt will be on the surface till you hit pay, and I wouldn't be contemplating stopeing till you have a good number of drives in, or the ground is suitable to take a stope, you don't want to go throwing crapy muddy ground in a stope when your taking panels, good hard rock, a mix of large and small, will see a nice tight fill.

all of the above is not really relevant if your 'Lead' mining, then you'll choose good solid ground, and sink until you hit the lead.

I do realise I missed quite a bit in this post, but I hope I've answerd most of your questions mate

Just realised I missed on of your questions mate, in reference to direction, by sinking in the footwall we can drive in to the ore body, once we hit the ore body we would put in a turn out cut, and start driving North and South, thus leading us to Development Ore Drives, so after we have sunk our shaft to its required depth, we would drive off to the East till we hit the ore body

Pheeeew, almost as long winded as a chapter of the 'Play'