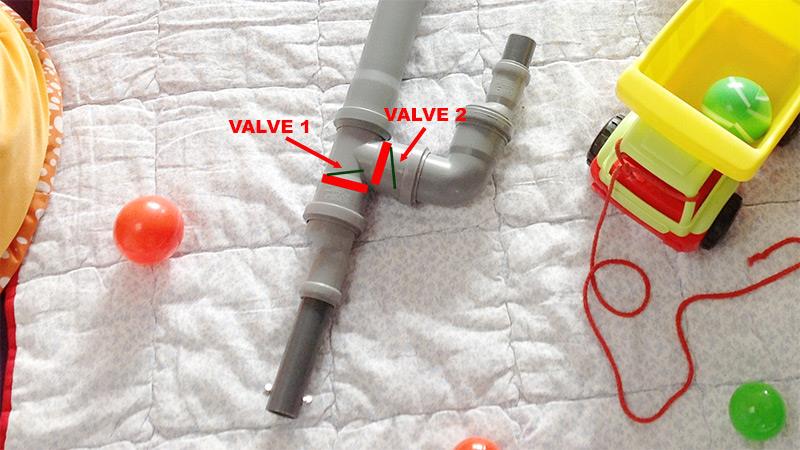

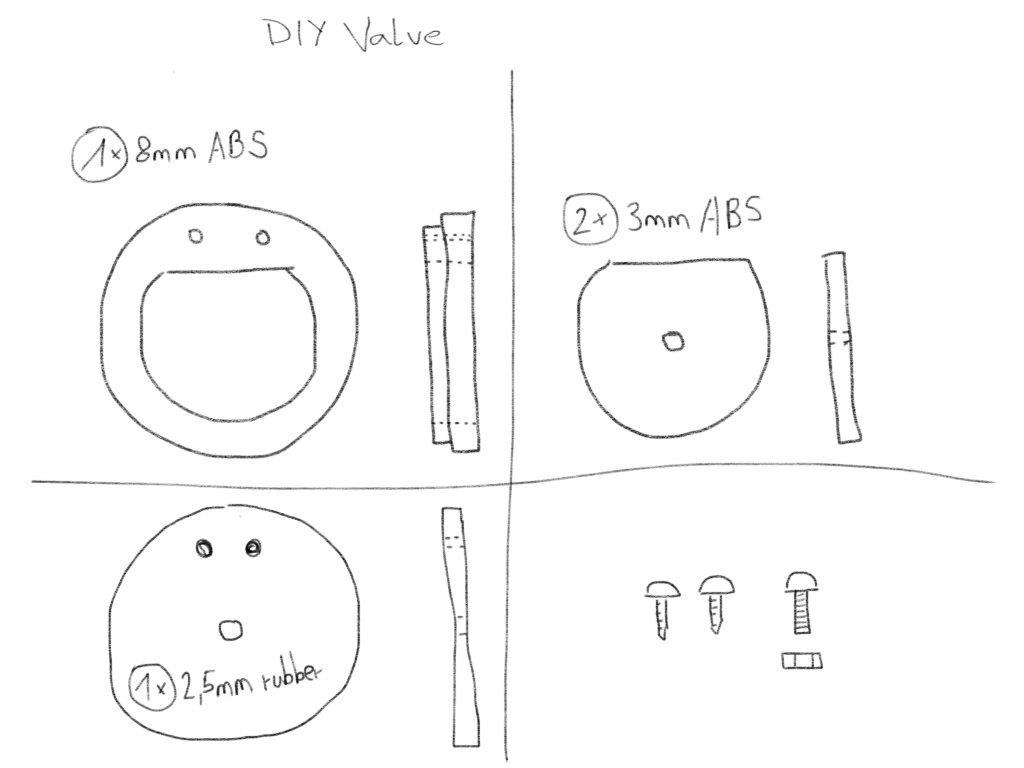

Hi All, thought I would share my ideas for the pump valves, I used a sink outlet 2 " , cut off the funnel and machined it down to clear the thread. You can skrew a 2" onto each end. Used 1.5 mm rubber for flap, but started with poly truck tarp. Cut down the stainless so one valve lets smaller particles through, what goes through the first valve goes through the second.

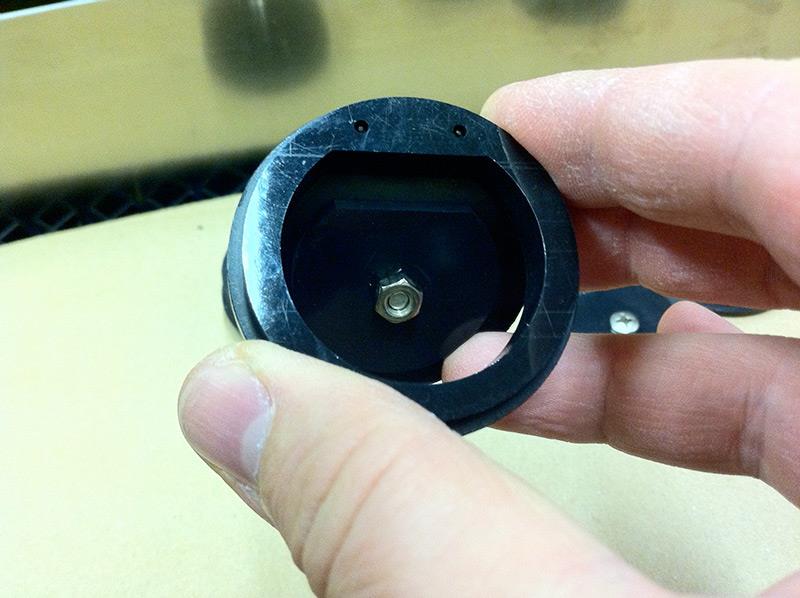

I made another valve out of a 2" floor waste, 50 mm flange and pipe, 1.5 mm rubber. screws and a 40 mm thred. All threds are 1.5"

Cheers All

I made another valve out of a 2" floor waste, 50 mm flange and pipe, 1.5 mm rubber. screws and a 40 mm thred. All threds are 1.5"

Cheers All