-

Please join our new sister site dedicated to discussion of gold, silver, platinum, copper and palladium bar, coin, jewelry collecting/investing/storing/selling/buying. It would be greatly appreciated if you joined and help add a few new topics for new people to engage in.

Bullion.Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crevicing / Small Picks information and questions

- Thread starter backcreek

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jan 2, 2017

- Messages

- 2,328

- Reaction score

- 3,015

I doubt you can re-shape a plough disc much as far as bending cold, due it's temper and corbon content. There is and acid type solution and process for hardening these days. Not involving heat.

mudgee hunter said:I doubt you can re-shape a plough disc much as far as bending cold, due it's temper and corbon content. There is and acid type solution and process for hardening these days. Not involving heat.

Not meaning to hijack this topic but can you expand on the acid hardening process ?

I have made my own pick from a plow disc. Not that easy to find second hand anymore. Cutting the shape out even took a good while with an 8 inch angle grinder with a cutting disc. I would have made a handle and was going to out of the local Eucalyptus Porosa and very hard fine grained timber but no access to a wood lathe. So I had to source one from eBay but couldn't find any that were actually had a round crossection just oval ones. Anyway welded a slightly flattened round tubular section onto the cut out head put a heap of Gorilla glue into the tube, put the handle in thena cut to length roofing teck into the predrilled hole and did up tight. After the glue set trimmed of the excess expaned glue. Sharpened the point slowly on a grinding wheel dipping in water to cool very often and then the srapping end. Painted the head black and most of the handle with bright orange marking paint. I have been told that it is easy to loose a pick in the bush hence the paint colour. The one I made has an18 inch handle 950 grams total. I also have one for Mrs Wishfull that is 850 grams and a larger Walco pick that is 1.8 kg with a 750 mm handle which isn't something you want to lug around all day.

Please excuse my changing from metric to imperial I was brought up with both but I'm mostly an imperialist.

Cheers. :Y:

Thanks for the comments guys. I was not going to attempt to shape the plough disc through any bending. I was going to use the natural curve and then just cut the shape out with an angle grinder. I actually found a home made pick when I was out on a creek a month ago. I could see that it was made from a plough disc. I reshaped it slightly and now use it every time I go out. The steel quality is quite good. The making will be a simple process (my background is a Wood/ metal teacher) but ideas in relation to shape will be the major consideration.

Thanks again.

Les

Thanks again.

Les

Look up Crevic Tool, I think, someone had them for sale .

- Joined

- Jan 2, 2017

- Messages

- 2,328

- Reaction score

- 3,015

RE/ Hardening acid process. Wishfull.

Its a new process that seems to getting used a lot in machinery. The large gears on our printers, aprox 100kg had this process done to them when i worked there. so it dose exist. Who, how and how much might be a google topic sorry mate. My old boss/owner was murdered sadly just over a year ago. So I have lost my direct info source.

Its a new process that seems to getting used a lot in machinery. The large gears on our printers, aprox 100kg had this process done to them when i worked there. so it dose exist. Who, how and how much might be a google topic sorry mate. My old boss/owner was murdered sadly just over a year ago. So I have lost my direct info source.

Just on tempering , sump oil is the oil of choice because of the higher carbon rate , welding and grinding and cutting destroy the temper so do the cuts then weld the handle holder on and dunk it immediately into sump oil the quick cooling and carbon in the used oil will give a degree of hardening , slow cooling after welding will cause a mild steel effect.Mungoman said:OP, to regain steels temper, it requires quenching in an organic substance like oil.

- Joined

- Jul 20, 2016

- Messages

- 2,274

- Reaction score

- 2,272

Les, dunno how long you have been doing it mate, as your post count said 10.

You said crevicing pick, I assume you mean for alluvial prospecting?

If so you'll need a completely different shape to detector picks.

I find for creek work a small crow bar and yabbie pump get used most, along with small scraping tools.

AND a brush.

You said crevicing pick, I assume you mean for alluvial prospecting?

If so you'll need a completely different shape to detector picks.

I find for creek work a small crow bar and yabbie pump get used most, along with small scraping tools.

AND a brush.

Hi occasional-panner,

I get where you are coming from. I use this gear also but I found that a pick comes in handy for starting the clean up of some of the crevices ( you know the ones that are always full of tightly packed gravel) I used a mates pick that was qiute narrow and sharp a couple of weeks ago and it came in quite handy for this purpose. As you guessed, I am a mug on a steep learning curve and need all the help I can get.

I must throw in a small crow bar next trip. Thanks for the advice. I have been using the yabbie pump with a slight modification (added a pvc reducer and 25mm pipe to give more suction and get into tighter corners and some crevices) I have only tried it once. It worked quite well and held the gravel/ clay a little longer due to the reducer. I want to give it a bit more time before a final judgement is made.

Aussie farmer,

Thanks for your wise words. Many moons ago (when I still had colour in my hair) we taught the students how to oil harden high carbon steels and then how to temper. Of course these days if you allow kids to handle luke warm water you could end up in jail for life.

One of the best inventions of the 20th century was the 1mm cutting disc for the angle grinder. They cut well without the huge heat generation. You are correct though, I will need to cut slowly to prevent the temper from being drawn. I will drop the pick into oil after the welding process.

Keep the ideas and comments coming. They have made the grey matter work overtime.

Cheers

Les

I get where you are coming from. I use this gear also but I found that a pick comes in handy for starting the clean up of some of the crevices ( you know the ones that are always full of tightly packed gravel) I used a mates pick that was qiute narrow and sharp a couple of weeks ago and it came in quite handy for this purpose. As you guessed, I am a mug on a steep learning curve and need all the help I can get.

I must throw in a small crow bar next trip. Thanks for the advice. I have been using the yabbie pump with a slight modification (added a pvc reducer and 25mm pipe to give more suction and get into tighter corners and some crevices) I have only tried it once. It worked quite well and held the gravel/ clay a little longer due to the reducer. I want to give it a bit more time before a final judgement is made.

Aussie farmer,

Thanks for your wise words. Many moons ago (when I still had colour in my hair) we taught the students how to oil harden high carbon steels and then how to temper. Of course these days if you allow kids to handle luke warm water you could end up in jail for life.

One of the best inventions of the 20th century was the 1mm cutting disc for the angle grinder. They cut well without the huge heat generation. You are correct though, I will need to cut slowly to prevent the temper from being drawn. I will drop the pick into oil after the welding process.

Keep the ideas and comments coming. They have made the grey matter work overtime.

Cheers

Les

Try this on a piece of scrap steel first to get the hang of it.

Half a bucket of Sand,

1/4 bucket of Charcoal crushed fine

3 cups sugar.

Mix the lot together very well and make sure it is dry.

After you are happy with your job, Heat the metal until

red hot.

Drop it into the mixture and cover it up real quick.

Give it about an hour then test with a file.

Be warned, You can still burn yourself if not careful.

Half a bucket of Sand,

1/4 bucket of Charcoal crushed fine

3 cups sugar.

Mix the lot together very well and make sure it is dry.

After you are happy with your job, Heat the metal until

red hot.

Drop it into the mixture and cover it up real quick.

Give it about an hour then test with a file.

Be warned, You can still burn yourself if not careful.

Lesgold said:Hi occasional-panner,

I get where you are coming from. I use this gear also but I found that a pick comes in handy for starting the clean up of some of the crevices ( you know the ones that are always full of tightly packed gravel) I used a mates pick that was qiute narrow and sharp a couple of weeks ago and it came in quite handy for this purpose. As you guessed, I am a mug on a steep learning curve and need all the help I can get.

I must throw in a small crow bar next trip. Thanks for the advice. I have been using the yabbie pump with a slight modification (added a pvc reducer and 25mm pipe to give more suction and get into tighter corners and some crevices) I have only tried it once. It worked quite well and held the gravel/ clay a little longer due to the reducer. I want to give it a bit more time before a final judgement is made.

Aussie farmer,

Thanks for your wise words. Many moons ago (when I still had colour in my hair) we taught the students how to oil harden high carbon steels and then how to temper. Of course these days if you allow kids to handle luke warm water you could end up in jail for life.

One of the best inventions of the 20th century was the 1mm cutting disc for the angle grinder. They cut well without the huge heat generation. You are correct though, I will need to cut slowly to prevent the temper from being drawn. I will drop the pick into oil after the welding process.

Keep the ideas and comments coming. They have made the grey matter work overtime.

Cheers

Les

G'day Les - i detect some old knowledge bubbling to the surface - we have the knowledge, greybeards rule :Y:

Hi Casper,

Jack of all trades, master of none. The problem with only having a small amount of knowledge is that you tend to get deeper into s#*t as you think you know it all. (Spend a heck of a lot of time here) The older you get, the more you learn. This growth in knowledge makes you realise how little you know.

This forum is a top place to learn (and to give). Unfortunately, l think that I'll be the student who will need to be taught for many years to come. I suppose that I can give more in the area of helping people in relation to constructing bits and pieces. Being a teacher of design, woodwork and metalwork for 36 years has been my career but also my passion. Now that I have retired, I will have the time to help out where I can in relation to this fascinating hobby.

Hey Wishfull, if you ever need a handle turned for one of those homemade picks, let me know.

Cheers

Les

Jack of all trades, master of none. The problem with only having a small amount of knowledge is that you tend to get deeper into s#*t as you think you know it all. (Spend a heck of a lot of time here) The older you get, the more you learn. This growth in knowledge makes you realise how little you know.

This forum is a top place to learn (and to give). Unfortunately, l think that I'll be the student who will need to be taught for many years to come. I suppose that I can give more in the area of helping people in relation to constructing bits and pieces. Being a teacher of design, woodwork and metalwork for 36 years has been my career but also my passion. Now that I have retired, I will have the time to help out where I can in relation to this fascinating hobby.

Hey Wishfull, if you ever need a handle turned for one of those homemade picks, let me know.

Cheers

Les

- Joined

- Jul 20, 2016

- Messages

- 2,274

- Reaction score

- 2,272

Plenty of info on youtube Les

https://www.youtube.com/watch?v=IhkMRrxjrPQ

https://www.youtube.com/watch?v=0ITwkHnAThg

https://www.youtube.com/watch?v=4-gfuZh0ppw

https://www.youtube.com/watch?v=E9gwYAzv1ac

https://www.youtube.com/watch?v=fEFCTVKjs1c

That should be a good start.

https://www.youtube.com/watch?v=IhkMRrxjrPQ

https://www.youtube.com/watch?v=0ITwkHnAThg

https://www.youtube.com/watch?v=4-gfuZh0ppw

https://www.youtube.com/watch?v=E9gwYAzv1ac

https://www.youtube.com/watch?v=fEFCTVKjs1c

That should be a good start.

- Joined

- Jul 20, 2016

- Messages

- 2,274

- Reaction score

- 2,272

These look good https://www.prospectingaustralia.com/forum/viewtopic.php?id=14338

Doesn't look like Ryan makes them any more, you could do it easily.

Here is another crevice thread to read https://www.prospectingaustralia.com/forum/viewtopic.php?id=12455&p=1

Doesn't look like Ryan makes them any more, you could do it easily.

Here is another crevice thread to read https://www.prospectingaustralia.com/forum/viewtopic.php?id=12455&p=1

Hi Guys,

Thanks for the info and ideas guys. I will be making a few of these tools. They are excellent. From what you have shown me, I assume that some of you are dentists......

Cheers

Les

Thanks for the info and ideas guys. I will be making a few of these tools. They are excellent. From what you have shown me, I assume that some of you are dentists......

Cheers

Les

- Joined

- May 25, 2015

- Messages

- 249

- Reaction score

- 314

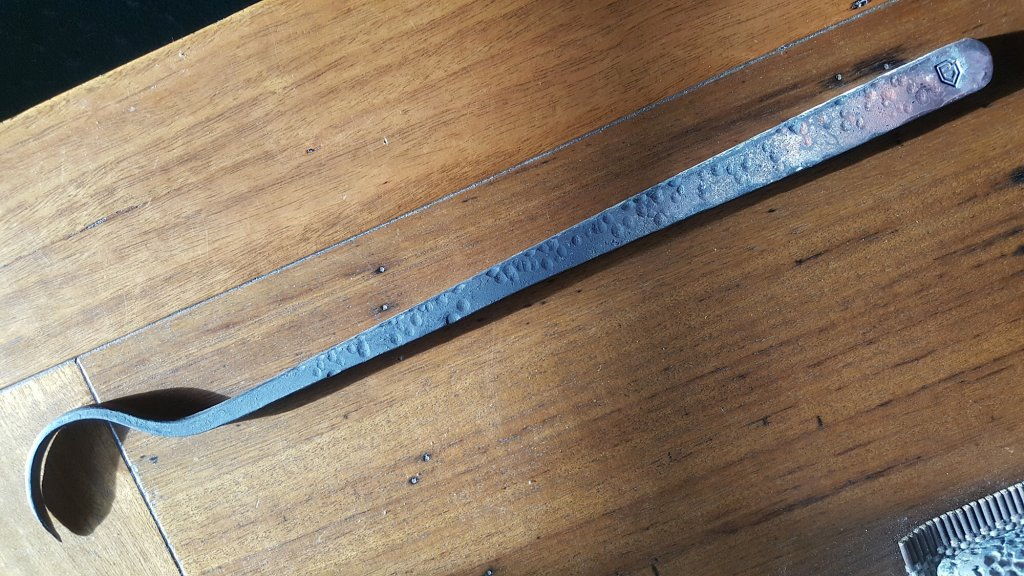

So I finally managed to find my crevice pick hiding deep in the shed and thought I'd share it...

It's a strip of 3mm stainless steel with a small scoop twisted into one end. At its widest point about 4mm and about 700 long. Small t handle for added control.

I find it works really well at getting down in deep crevices but definitely doesn't make gold magicly appear.

It's a strip of 3mm stainless steel with a small scoop twisted into one end. At its widest point about 4mm and about 700 long. Small t handle for added control.

I find it works really well at getting down in deep crevices but definitely doesn't make gold magicly appear.

Aussiedigs

Al.

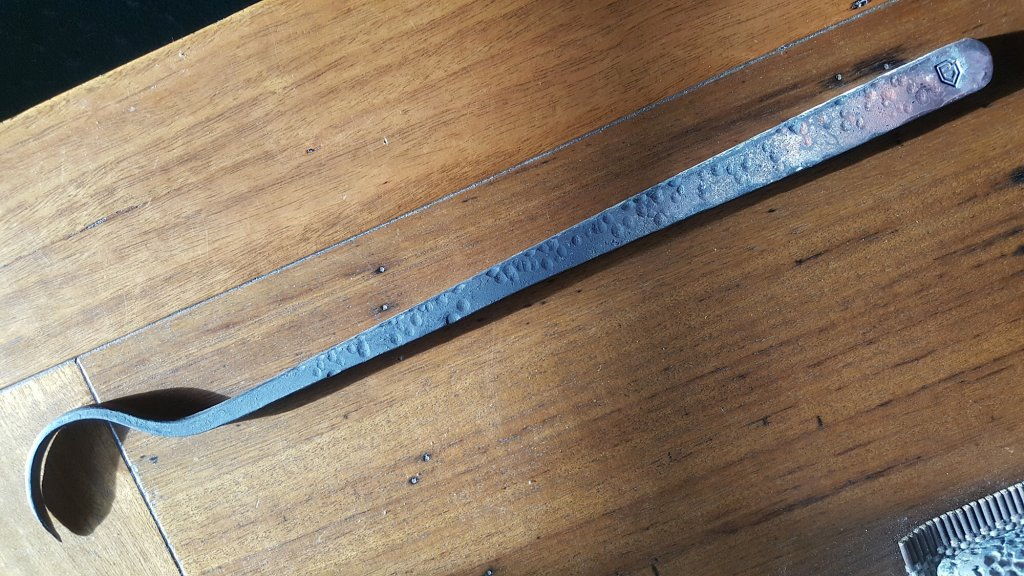

No, i didnt make it, but Baz a member here did.

Baz is in The area prospecting with his son. This is a gift from Baz.

Made out of a Landrover leaf spring, tempered and heat treated to perfection. (Let me know if ive got that wrong Baz if you read this).

Baz showed me pics of his knives. This fella has serious talent!

Baz is in The area prospecting with his son. This is a gift from Baz.

Made out of a Landrover leaf spring, tempered and heat treated to perfection. (Let me know if ive got that wrong Baz if you read this).

Baz showed me pics of his knives. This fella has serious talent!

Aussiedigs said:No, i didnt make it, but Baz a member here did.

Baz is in The area prospecting with his son. This is a gift from Baz.

Made out of a Landrover leaf spring, tempered and heat treated to perfection. (Let me know if ive got that wrong Baz if you read this).

Baz showed me pics of his knives. This fella has serious talent!

Land Rover? It'll leak or Lucas the prince of darkness will extinguish the lights :lol: :lol:

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 17

- Views

- 3K

- Replies

- 55

- Views

- 9K