Having sold the VJ as Dinah was having back troubles using it, we've been looking around to pick up a Gemmasta. Friday night I spotted a Gumtree ad for a Topaz Tec, but like no Topaz Tec I had ever seen so headed off to check it out. It was easy to see this was a bit different, the engineering looked good and the machine ticked a lot of boxes, plus it was really clean. Turned out is had been sitting for 2 years, anyway.. bit the bullet and bought it; $3k

We started the strip and clean once we got home and it wasn't long before we discovered just how good the engineering in this machine is. Everything is was smooth as silk, except for a bit of binding on grub

Started cleaning the head and discovered the angle arc spindle sits in a good sized, sealed bearing, not only that the rotating face had a 50mm thrust bearing so it'll never run out or wear!

so it'll never run out or wear!

Clean simple base, no clutter and a rubber mat to stand bits and pieces on:

As we progressed it became apparent someone had been tinkering as the tension washers on the spindle/lap adjusters had been fitted incorrectly and there were spring washers on the bolts so nothing moved... easy fix

Splash bowl with two spun ali covers, one for girdles and a second fully enclosed cover, plus the bowl adjusts in height and quickly lifts off for cleaning :inlove:

Came with 4 index wheels, several are double sided and you can select the coloured dots for either multiples of 3 or 4 to minimise confusion, plus seriously clear markings.

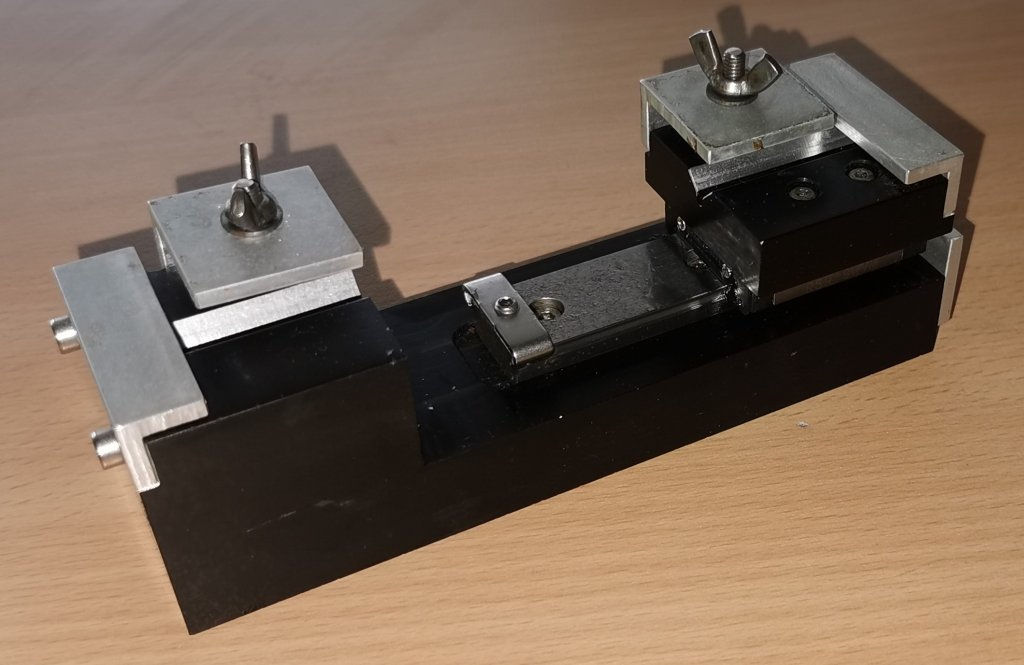

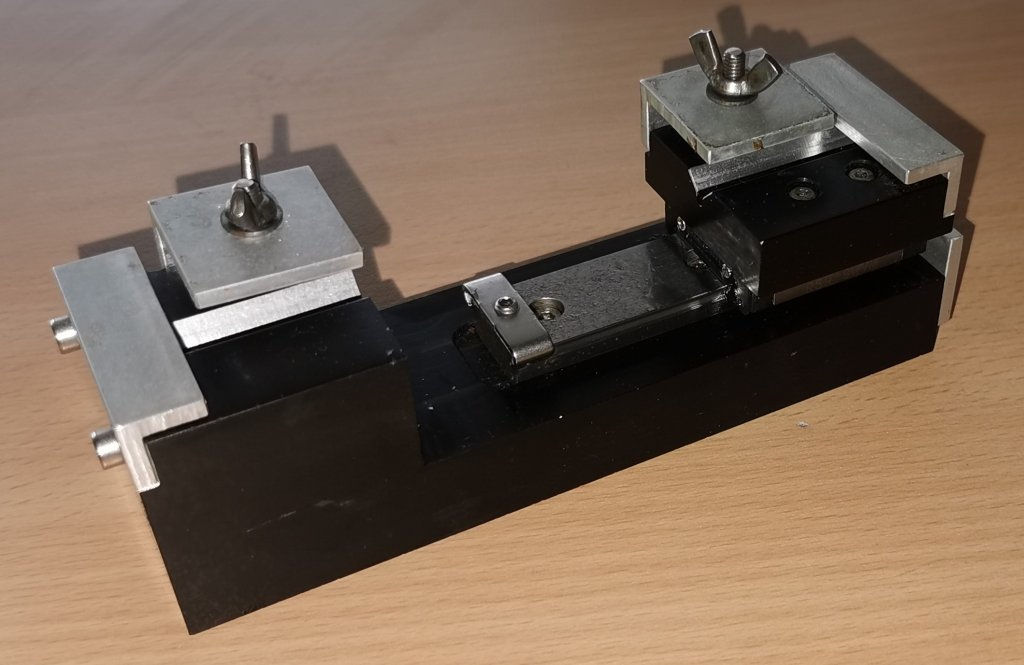

Dinah decided to clean the transfer jig, suddenly a scream for help as she has tiny ball bearings going everywhere :awful: Turns out the transfer slide runs on a linear bearing!! Fortunately a magnet found all the balls layful:

layful:

After that disaster, she decided not to tinker but do some reading. Turns out the machine was made in 1997/8, serial number 6021 and when purchased the price was $3900 I think this machine shares an engineering spot with such as the Hall 2000 extended and they could genuinely be considered as the "Rolls Royce" of faceting machines. I'm in awe of what Glen Booth designed and made.

but do some reading. Turns out the machine was made in 1997/8, serial number 6021 and when purchased the price was $3900 I think this machine shares an engineering spot with such as the Hall 2000 extended and they could genuinely be considered as the "Rolls Royce" of faceting machines. I'm in awe of what Glen Booth designed and made.

We started the strip and clean once we got home and it wasn't long before we discovered just how good the engineering in this machine is. Everything is was smooth as silk, except for a bit of binding on grub

Started cleaning the head and discovered the angle arc spindle sits in a good sized, sealed bearing, not only that the rotating face had a 50mm thrust bearing

Clean simple base, no clutter and a rubber mat to stand bits and pieces on:

As we progressed it became apparent someone had been tinkering as the tension washers on the spindle/lap adjusters had been fitted incorrectly and there were spring washers on the bolts so nothing moved... easy fix

Splash bowl with two spun ali covers, one for girdles and a second fully enclosed cover, plus the bowl adjusts in height and quickly lifts off for cleaning :inlove:

Came with 4 index wheels, several are double sided and you can select the coloured dots for either multiples of 3 or 4 to minimise confusion, plus seriously clear markings.

Dinah decided to clean the transfer jig, suddenly a scream for help as she has tiny ball bearings going everywhere :awful: Turns out the transfer slide runs on a linear bearing!! Fortunately a magnet found all the balls

After that disaster, she decided not to tinker