Welcome Prooz, my wife and I both have Hall machines, I use a 2000 and once 'tuned in' it's an awesome machine, my wife has an Xtra which is good but not brilliant on the ergonomics, particularly if you have to wear glasses. Both machines have the capacity to produce competition winning stones. In last year's AFG comp a novice scored something like 97/100 for one of her stones and she used a Hall Xtra.

So what to look for:

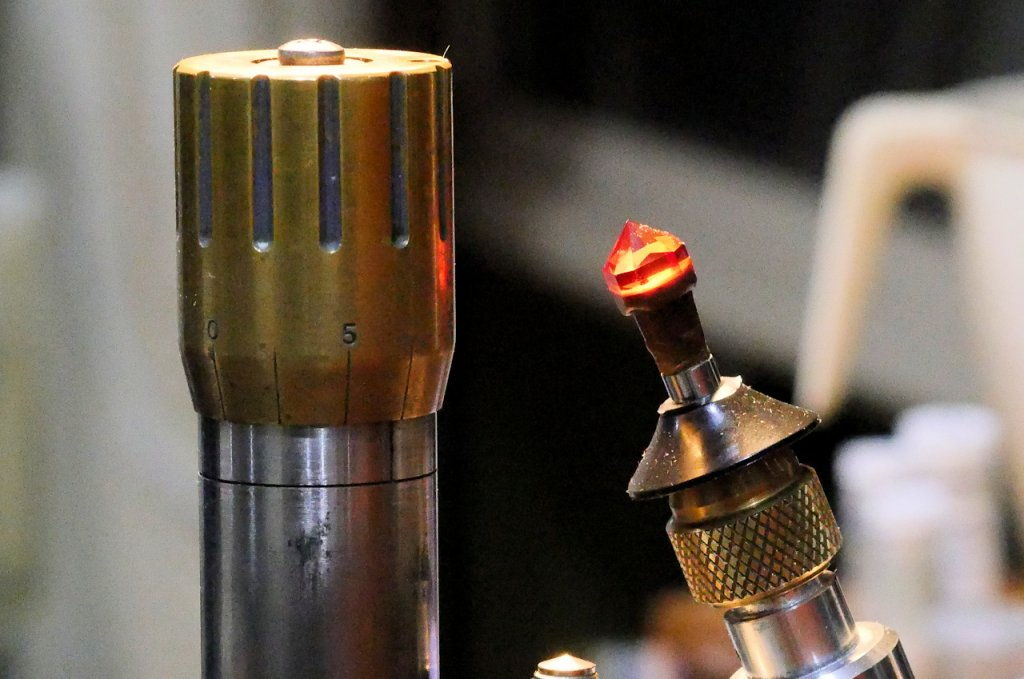

1. Play in the quill bearings, both laterally and longitudinally.

2. Main spindle bearings, leaking oil and noise, noise is a give away, they should purr. Very easy to replace

3. Bent master lap. Put a dop in the quill, set it on the master lap and zero the gauge, now slowly rotate the master lap. The Dial should not move off zero, if it does you will either need the master re-machined or a new one made. If the master is out/bent you will never be able to cut an accurate stone.

4. If the lap is true, set the quill close to the perimeter of the lap directly above one of the adjusting nuts, there are 3 sitting under the bowl. These are used for lap alignment. With your first position zero the dial, now lift the dop and move the mast base so the dop sits above each of the other nuts and see how much variation there is in the readings. DON'T touch the mast adjuster, all you want to do is move the quill and mast position.

5. The hardest thing to tell is if you have a bent mast, you need a workshop to test this.

Other than those checks there are the obvious like general condition etc. Worth taking a straight edge so you can check hollowing on the polishing laps if there are any with the package, this will tell you a lot about the user, I dress mine regularly to keep them flat, too much hollowing and I'm fighting to keep a stone and the meets accurate.

In general if you have some mechanical 'know how', machines are relatively straight forward to service, bearings are readily available and some common sense goes a long way.

Good luck with your search.