- Joined

- Jul 2, 2013

- Messages

- 4

- Reaction score

- 6

Hi All,

I will apologise now that this may be a long post, or 2.

After digging & gathering up pretty rocks for a few years, & cabbing for a while too. I have been learning to facet for the last little while. Limited free time, combined with a touch of the old O.C.D. means its a steep learning curve. Ive found tons of really helpful inspiration here from you guys. So here I am writing this in the hope it helps any of you in return.

Since starting up I often read mainly on overseas forums, that any topper lap will do for roughing & cutting. But then there is an ever-expanding list of recommendations for stone specific pre-polish & polishing laps. Meanwhile there is a steady stream of newbies like me, having a hard time getting a good pre-polish / polish, & asking for help. This has me scratching my head lately. I have given that advice a really good go already & maybe its just me. But I am finding that a different strategy absolutely transforms the process for me. Which is the reason for my post.

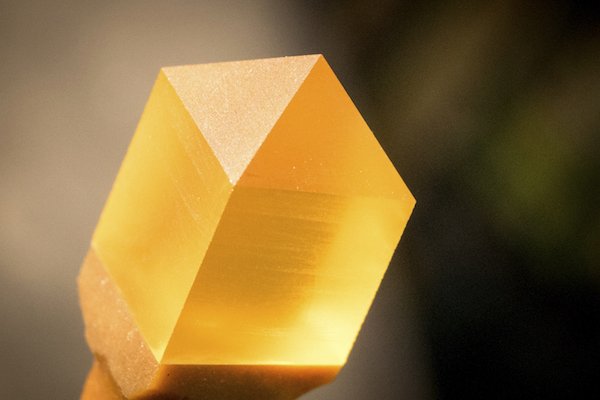

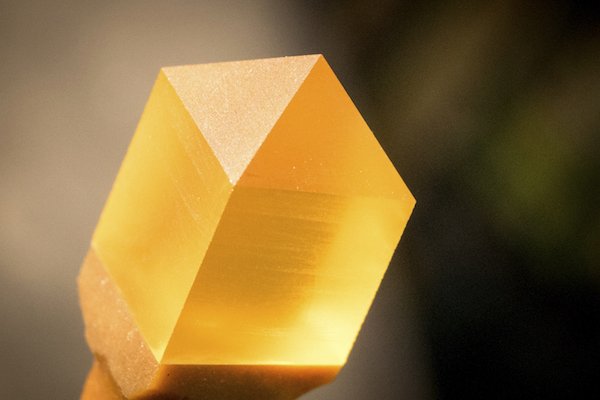

So to show you what I am on about, here is a sacrificial bit of Cristinite. Its been repeatedly cut as a pyramid while tuning up my old Gemmasta, all the way down to the wax.

Usually with me doing the cutting, the edges to chip pretty significantly on Cristinite, that is using plated laps all the way up to 1200. Cristinite is a bit of a bugger for me. Then again opal, quartz, topaz, tourmaline, & sapphire all have their own reasons to be a bugger too. You guys will probably know what I mean.

This pic is actually showing the finish from Rough2Cuts (Tony Fitzgerald) 360 grit sintered lap. Its super balanced & ultra flat. It removes material like a wood chipper. But I can get it to leave a clean, flat undamaged surface like this, even on cristinite. I reckon thats worthy of some praise for this lap.

The other most common advice Ive seen is that sintered laps are too expensive. But I reckon the speed gained due to the lack of damage they cause is well worth the cost to me personally. I have come to see that for me, the amount of damage I cause in roughing & cutting has a far bigger influence on the speed I can get through the job than pretty much anything else. It didn't really click for me when starting up, so maybe I am preaching to the choir here already. But I thought I should share it just the same.

My original lap purchases have now mostly been replaced with Tonys laps. I run the 360 grit sintered, for most rough cutting. For fine cutting through to polish I am using Tonys 8 fast cutting system with 800 sintered outer rim, & a couple of interchangeable pre-polish/ polish centre laps depending on the stone. I love not having to change the stone height to go from cutting to pre-polish to polish. Im using his polishing compounds too. So I will take some pics showing results of these too, as I am similarly impressed. But this is probably long enough for now.

Hope it helps.

I will apologise now that this may be a long post, or 2.

After digging & gathering up pretty rocks for a few years, & cabbing for a while too. I have been learning to facet for the last little while. Limited free time, combined with a touch of the old O.C.D. means its a steep learning curve. Ive found tons of really helpful inspiration here from you guys. So here I am writing this in the hope it helps any of you in return.

Since starting up I often read mainly on overseas forums, that any topper lap will do for roughing & cutting. But then there is an ever-expanding list of recommendations for stone specific pre-polish & polishing laps. Meanwhile there is a steady stream of newbies like me, having a hard time getting a good pre-polish / polish, & asking for help. This has me scratching my head lately. I have given that advice a really good go already & maybe its just me. But I am finding that a different strategy absolutely transforms the process for me. Which is the reason for my post.

So to show you what I am on about, here is a sacrificial bit of Cristinite. Its been repeatedly cut as a pyramid while tuning up my old Gemmasta, all the way down to the wax.

Usually with me doing the cutting, the edges to chip pretty significantly on Cristinite, that is using plated laps all the way up to 1200. Cristinite is a bit of a bugger for me. Then again opal, quartz, topaz, tourmaline, & sapphire all have their own reasons to be a bugger too. You guys will probably know what I mean.

This pic is actually showing the finish from Rough2Cuts (Tony Fitzgerald) 360 grit sintered lap. Its super balanced & ultra flat. It removes material like a wood chipper. But I can get it to leave a clean, flat undamaged surface like this, even on cristinite. I reckon thats worthy of some praise for this lap.

The other most common advice Ive seen is that sintered laps are too expensive. But I reckon the speed gained due to the lack of damage they cause is well worth the cost to me personally. I have come to see that for me, the amount of damage I cause in roughing & cutting has a far bigger influence on the speed I can get through the job than pretty much anything else. It didn't really click for me when starting up, so maybe I am preaching to the choir here already. But I thought I should share it just the same.

My original lap purchases have now mostly been replaced with Tonys laps. I run the 360 grit sintered, for most rough cutting. For fine cutting through to polish I am using Tonys 8 fast cutting system with 800 sintered outer rim, & a couple of interchangeable pre-polish/ polish centre laps depending on the stone. I love not having to change the stone height to go from cutting to pre-polish to polish. Im using his polishing compounds too. So I will take some pics showing results of these too, as I am similarly impressed. But this is probably long enough for now.

Hope it helps.