no please hijack all you like, i dont mind it evolving to related subjects at all when it comes to set ups etc

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

riffle setup with expanded metal

- Thread starter jamie

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Next1m8

Chris

Any suggestions would be helpful thanks

Howdy Next1, riffles are usually governed by your pump size/water flow, in a nutshell, you want the water to skip over your riffle, and at least start to flatten out and build up speed before it hits the next riffle, this helps keep the sluice box clear of lights, and assists in creating a few dead zones ( slow moving, low pressure areas) around the riffle enabling heavies to drop out, some of the better riffles I have seen and used are the Hungarian style riffle,Next1m8 said:just wondering if anyone has any modification suggestions for this, I've tried with just expanded metal and miners moss, found that it let way to much fine material through, so I tried it without miners miss and a 6$ shower mat from reject shop and it caught all the fine material well just wondering if I should put smaller rifles and extend them up further? I tried the flat steel on a 45degree angle and washing washing off the larger rocks very well so I'm considering putting in smaller rifles with maybe a bigger gap between them?

Any suggestions would be helpful thanks

Personally, I have found using a 2 inch high pressure fire fighting pump, only a few rpm above idle, I usually keep my riffles in comparison with the width of the box, 400mm wide sluice box, 400mm between riffles, and of course riffle height is governed by screening size.

Ps, the above method is my personal choice, as for the 400mm x 400mm theory, well I blew that outa the water when I built a 100mm sluice for a mate, I then found that under 300mm wide, I added 100mm to the distance between riffles and that seemed to return the water back to its pressured/low pressure state

dwt, have you used 'modified clarkson riffles' sloped at 15 deg. upstream like a lot of the US reports on sluice design recommend? if so how did you find them? i was thinking of setting mine up like it to see how it goes, have to admit i have been busy and lazy so i haven't finished my banker yet

Next1m8

Chris

dwt said:Howdy Next1, riffles are usually governed by your pump size/water flow, in a nutshell, you want the water to skip over your riffle, and at least start to flatten out and build up speed before it hits the next riffle, this helps keep the sluice box clear of lights, and assists in creating a few dead zones ( slow moving, low pressure areas) around the riffle enabling heavies to drop out, some of the better riffles I have seen and used are the Hungarian style riffle,Next1m8 said:just wondering if anyone has any modification suggestions for this, I've tried with just expanded metal and miners moss, found that it let way to much fine material through, so I tried it without miners miss and a 6$ shower mat from reject shop and it caught all the fine material well just wondering if I should put smaller rifles and extend them up further? I tried the flat steel on a 45degree angle and washing washing off the larger rocks very well so I'm considering putting in smaller rifles with maybe a bigger gap between them?

Any suggestions would be helpful thanks

Personally, I have found using a 2 inch high pressure fire fighting pump, only a few rpm above idle, I usually keep my riffles in comparison with the width of the box, 400mm wide sluice box, 400mm between riffles, and of course riffle height is governed by screening size.

Ps, the above method is my personal choice, as for the 400mm x 400mm theory, well I blew that outa the water when I built a 100mm sluice for a mate, I then found that under 300mm wide, I added 100mm to the distance between riffles and that seemed to return the water back to its pressured/low pressure state

I was thinking dwt, that my riffles are to close as the water is transferring way to fast between them and not really creating a dead zone sadly it's kinda more like a gushing torrent, I found when I remove them it's way more effective at removing all lights, I'm just worried with the size of expanded mesh that I may run the risk of losing my larger gold pieces and river gems I've been finding lots of little blue ones and some nice sized red ones. I come up around Bendigo/castlemain a bit is there any chance you may let me join you? Currently I'm using an apparent 2000 gph 12v pump I highly doubt that's it's true output however

the 'dead zone' will be created behind the riffle and that is where your heavies will drop, if it is creating the exchange area behind your riffles you are prob doing ok, from the photos they dont look to close together

In my short time prospecting i have never seen gold get pass that setup. Unless its on a ridiculous angle ? Even so the large gold wont move...ive seen flat gold float straight through but its small. I reckon its catching all heavys.

cracka

Craig

Check this out, a bit long but some great info in there.

http://www.hecklerfabrication.com/files/sluice-build-partIII-2.pdf

And this one for riffle size and spacing.

http://www.hecklerfabrication.com/files/Clarkson_Riffle_Test.pdf

Read both a few times before I even tried to build a sluice. Enjoy.

Cracka

http://www.hecklerfabrication.com/files/sluice-build-partIII-2.pdf

And this one for riffle size and spacing.

http://www.hecklerfabrication.com/files/Clarkson_Riffle_Test.pdf

Read both a few times before I even tried to build a sluice. Enjoy.

Cracka

Top post matecracka said:Check this out, a bit long but some great info in there.

http://www.hecklerfabrication.com/files/sluice-build-partIII-2.pdf

And this one for riffle size and spacing.

http://www.hecklerfabrication.com/files/Clarkson_Riffle_Test.pdf

Read both a few times before I even tried to build a sluice. Enjoy.

Cracka

No I havnt mate, to be honest I've read the name Clarkson here a few times but never looked into it, I purchased a book some years ago called "fists full of gold" by Chris Ralph, I studed his riffle ideas then started playing around with them from there, from memory all up I've ran some 20-30 different types of riffles in testing, some success and some downright laughable failures, not to include the ones when I stood back, paused, and having a good cack to myself as to how idiotic and out there they really were :lol:jamie said:dwt, have you used 'modified clarkson riffles' sloped at 15 deg. upstream like a lot of the US reports on sluice design recommend? if so how did you find them? i was thinking of setting mine up like it to see how it goes, have to admit i have been busy and lazy so i haven't finished my banker yet

I've tried flatbar tall and short, different angles, flat bar with holes in it (that was scotch induced) pressed M shaped riffles, wich had mixed results!, 1/4 section 25mm tube riffles, 1/2 section 25mm tube riffles that were set up with low water pressure to create a dead zone, round tube riffles, angle iron differing sizes, on top of all that, degree changes from 90 down to about 10, spacing of riffles from close to far apart, pressed sheet, now that's were ***** gets really outa control, so out of all that testing I eventually came back to slightly modified Hungarian style riffles.

I was working on nugget trap Hungarian riffle for a while but I havnt had a chance to test them out in a sluice box yet,

So when you add up all the time spent testing/making different types of riffles, and then start to think about sluice box lengths, heights, angles, pitches, widths, then include water pressures and volumes............well I guess you can see why I havnt tested for awhile, basically I'd had enough of trying to reinvent the wheel, half my gear is going to need to be spider sprayed and have wasps nests smashed off them before the rains hit too

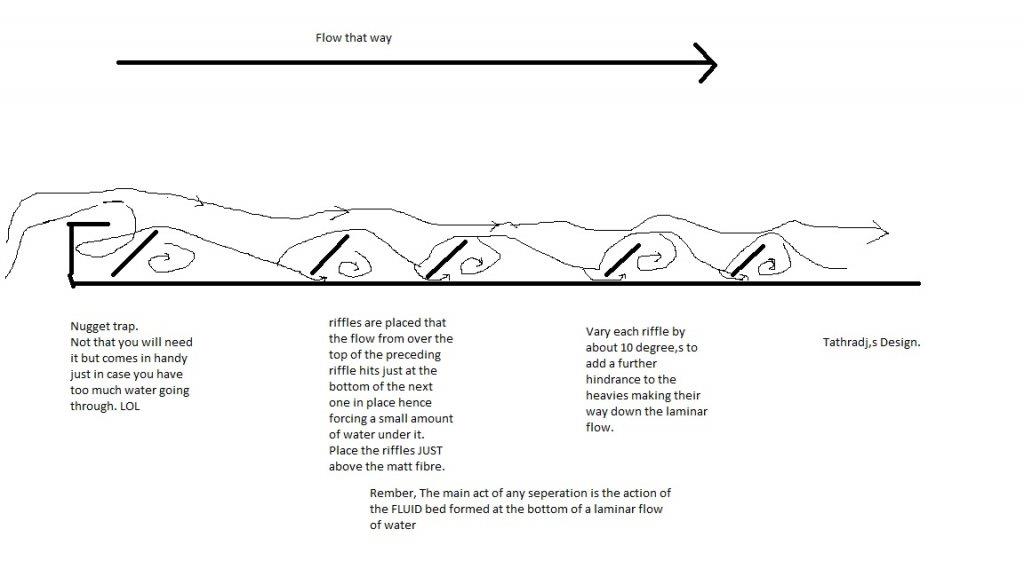

No issues in blocking on your underflowy thingy's (under the riffles)?Tathradj said:Gotta add this one mate.

Just had a quick scrawl with paint.

THIS is my big secret riffle design that in a WalBanker works extremely well.https://www.prospectingaustralia.com/forum/img/member-images/2436/1427798385_riffle_setup.jpg

For me any way.

Thank you for that response dwt, greatly appreciate the time put in for the reply, lots of experience there that i respect and appreciate the sharing of that.

When we were at Oallan Ford i looked at your riffle set up Doug, and was impressed by it, proper thought and time put into your design and seems to work well

When we were at Oallan Ford i looked at your riffle set up Doug, and was impressed by it, proper thought and time put into your design and seems to work well

.dwt said:No issues in blocking on your underflowy thingy's (under the riffles)?Tathradj said:Gotta add this one mate.

Just had a quick scrawl with paint.

THIS is my big secret riffle design that in a WalBanker works extremely well.https://www.prospectingaustralia.com/forum/img/member-images/2436/1427798385_riffle_setup.jpg

For me any way.

No problem there DWT. The pressure wave from the preceding riffle keeps that area clear.

Very cool mate, I'm guessing that your running standard degree ratio, 9.5-10 or can you go steeper having that set up?Tathradj said:.dwt said:No issues in blocking on your underflowy thingy's (under the riffles)?Tathradj said:Gotta add this one mate.

Just had a quick scrawl with paint.

THIS is my big secret riffle design that in a WalBanker works extremely well.https://www.prospectingaustralia.com/forum/img/member-images/2436/1427798385_riffle_setup.jpg

For me any way.

No problem there DWT. The pressure wave from the preceding riffle keeps that area clear.

It all depends on the material you are processing.

4:1 start then throw a couple of shovel fulls in.

Watch the action just in under the first and second riffle. You will see the fluid bed come to life and if it is too aggressive, drop your water flow and angle either way to improve it.

.

Other thing to watch is the wave coming over the top and hitting the back of the riffle in front. It HAS to impact just on the bottom of the riffle.

The water flow over the top of the riffle causes a small vacuum pulling water in under the bottom of the riffle. It is not much but makes a big impact on keeping black sand interfering with the process. Gold being the heaviest drops down into the mat and stays there.

Idea come about as I was thinking of building a set of hydraulic riffles. I bit of a pain to do and not really suited to a small "Hobby" Sluice.

Penny dropped. Why use a forced action to keep the bed agitated. Falling water does the same trick.

If the sediment is building up too much between the riffles, You have not paid attention to your flow/Angle. .

.

When working properly you will see a fine band of black sand just in under the riffle with the area behind it nearly clear. That is where the gold is buried in the mat.

And that is the stuff that comes past your expanded without you knowing about it.

4:1 start then throw a couple of shovel fulls in.

Watch the action just in under the first and second riffle. You will see the fluid bed come to life and if it is too aggressive, drop your water flow and angle either way to improve it.

.

Other thing to watch is the wave coming over the top and hitting the back of the riffle in front. It HAS to impact just on the bottom of the riffle.

The water flow over the top of the riffle causes a small vacuum pulling water in under the bottom of the riffle. It is not much but makes a big impact on keeping black sand interfering with the process. Gold being the heaviest drops down into the mat and stays there.

Idea come about as I was thinking of building a set of hydraulic riffles. I bit of a pain to do and not really suited to a small "Hobby" Sluice.

Penny dropped. Why use a forced action to keep the bed agitated. Falling water does the same trick.

If the sediment is building up too much between the riffles, You have not paid attention to your flow/Angle. .

.

When working properly you will see a fine band of black sand just in under the riffle with the area behind it nearly clear. That is where the gold is buried in the mat.

And that is the stuff that comes past your expanded without you knowing about it.

Awesome mate, well done, looking forward to seeing it in actionTathradj said:It all depends on the material you are processing.

4:1 start then throw a couple of shovel fulls in.

Watch the action just in under the first and second riffle. You will see the fluid bed come to life and if it is too aggressive, drop your water flow and angle either way to improve it.

.

Other thing to watch is the wave coming over the top and hitting the back of the riffle in front. It HAS to impact just on the bottom of the riffle.

The water flow over the top of the riffle causes a small vacuum pulling water in under the bottom of the riffle. It is not much but makes a big impact on keeping black sand interfering with the process. Gold being the heaviest drops down into the mat and stays there.

Idea come about as I was thinking of building a set of hydraulic riffles. I bit of a pain to do and not really suited to a small "Hobby" Sluice.

Penny dropped. Why use a forced action to keep the bed agitated. Falling water does the same trick.

If the sediment is building up too much between the riffles, You have not paid attention to your flow/Angle. .

.

When working properly you will see a fine band of black sand just in under the riffle with the area behind it nearly clear. That is where the gold is buried in the mat.

And that is the stuff that comes past your expanded without you knowing about it.

Next1m8

Chris

Done some modifications to the high banker, added my miners moss back in over laying my reject shop mat & rubber mat - reason being I find the miners moss lets too much trough, so my reject shop mat will catch that. Also added some plastic in the back of my sluice tray to stop stuff getting caught up the back, drove me mental. Also put my riffles back in due to the material I'm running being clay and what not so I need a sort of scrubber bcos I don't have a wash trommel I wish I did

Hopefully I put this in the right section now

Hopefully I put this in the right section now

Next1m8

Chris

Would anyone be interested in having a hand in running a few test on this to see if it's running right and give me any extra advice? I am tired of reading stuff, I love all the suggestions now but just need someone experienced to come for a run with me

looks pretty good mate, if i was in that area i would go out and test it with you but again i am no expert so not sure if i could help a lot

Similar threads

- Replies

- 24

- Views

- 11K