-

Please join our new sister site dedicated to discussion of gold, silver, platinum, copper and palladium bar, coin, jewelry collecting/investing/storing/selling/buying. It would be greatly appreciated if you joined and help add a few new topics for new people to engage in.

Bullion.Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

G

Guest

I run 2mm round hole jetting, have done now for years never had any trouble with blockages and find them the best for me on clay. But then it all depends on what type of gear your running and the strainer you are using. Slots I found also increases your fuel use which is an important factor when out on a long stay where every drop needs to be accounted for. Its good to hear different ideas. Cheers thanks

Soak Hole Pumping.

Where this idea originally came from we will never know, it is now lost in the dim misty shadows of time. Just what is soak hole pumping. Well it was a few years ago now, Dry hot and not a drop of water in the creek I was working and I was on good gold. Bugger I was in a pickle right enough. Finding an area to work in the right place was hard enough but getting the water to work the area now that was going to be a bit tricky. I remembered been told about digging a soak hole for water. The hole must be at the end or beginning of a large pond or pool, you then dig down on the lowest side of the pond or pool in the creek bed to find the water. As we know when a creek is dry on top there is a 90% chance that there is sub surface water not always but there is most times. The hole must be a big one a few meters wide, long and deep as shown in the photos I posted earlier on in this thread.

https://www.prospectingaustralia.com/forum/viewtopic.php?pid=210328#p210328

Pump size is important you can only work the little inch pumps with any success, the 1&1/2 inch pumps are two strong even at idle and will very quickly take your water away. Your foot valve filter must also be in top shape or you will suck up sand and junk and block your system real quick {You got to watch that}, The deeper you can get your pumps pick up hose the better and try to run the discarded water from the banker back into the pool or pond through sand this will prolong your working life of the water.

Soak Hole Pumping.

Where this idea originally came from we will never know, it is now lost in the dim misty shadows of time. Just what is soak hole pumping. Well it was a few years ago now, Dry hot and not a drop of water in the creek I was working and I was on good gold. Bugger I was in a pickle right enough. Finding an area to work in the right place was hard enough but getting the water to work the area now that was going to be a bit tricky. I remembered been told about digging a soak hole for water. The hole must be at the end or beginning of a large pond or pool, you then dig down on the lowest side of the pond or pool in the creek bed to find the water. As we know when a creek is dry on top there is a 90% chance that there is sub surface water not always but there is most times. The hole must be a big one a few meters wide, long and deep as shown in the photos I posted earlier on in this thread.

https://www.prospectingaustralia.com/forum/viewtopic.php?pid=210328#p210328

Pump size is important you can only work the little inch pumps with any success, the 1&1/2 inch pumps are two strong even at idle and will very quickly take your water away. Your foot valve filter must also be in top shape or you will suck up sand and junk and block your system real quick {You got to watch that}, The deeper you can get your pumps pick up hose the better and try to run the discarded water from the banker back into the pool or pond through sand this will prolong your working life of the water.

G

Guest

For pump and hose information go to this line of post. There has been some good information posted which will give you good guidance.

https://www.prospectingaustralia.com/forum/viewtopic.php?id=14796

Jembaicumbene

https://www.prospectingaustralia.com/forum/viewtopic.php?id=14796

Jembaicumbene

G

Guest

Well we covered a fair bit so far. One very bit of important gear the high-banker. Boy where to start with this one! First off you will hear my banker is better than that banker it gets more gold or buy this banker it can do hand stands. The fact of the matter is they all work pretty much the same in regards to gold retention. Some a little better than others but that only comes down to a few extra shovels of wash. Your concern is getting the right banker that ticks all your boxes. But to find out what boxes need ticking here is a quick guide for starters.

What I would look for in a banker

1- My first consideration would be space for the banker in my vehicle along with all the other gear including camping gear.

2- What is the banker like to set up. Fiddley or simple

.

3- Ease of operation when shovelling wash dirt into the bankers top hopper.

4- Ease of clean up.

5- The amount of concentrate you will need to clean up to get the gold.

5- Pump size to drive the unit.

6- Is the banker made to last {solid}

7- The bankers weight.

8- Try and learn as much as I can about the banker from prospecting forums, and from people who are using them.

For starters

Check this thread out some good information embedded within its pages.

https://www.prospectingaustralia.com/forum/viewtopic.php?id=1115

Or you could look up this site but remember do not jump in and buy the first banker you see take the time do your research, ask the questions and youll be ok.

http://www.Highbanker.com.au

What I would look for in a banker

1- My first consideration would be space for the banker in my vehicle along with all the other gear including camping gear.

2- What is the banker like to set up. Fiddley or simple

.

3- Ease of operation when shovelling wash dirt into the bankers top hopper.

4- Ease of clean up.

5- The amount of concentrate you will need to clean up to get the gold.

5- Pump size to drive the unit.

6- Is the banker made to last {solid}

7- The bankers weight.

8- Try and learn as much as I can about the banker from prospecting forums, and from people who are using them.

For starters

Check this thread out some good information embedded within its pages.

https://www.prospectingaustralia.com/forum/viewtopic.php?id=1115

Or you could look up this site but remember do not jump in and buy the first banker you see take the time do your research, ask the questions and youll be ok.

http://www.Highbanker.com.au

Im in the process of designing a new one so ill explain what ive got going on

1 - keep my sluices so they easily fit in my boot or anyone elses car with ease. Sluice extensions slide inside one another incrementing down in size.

2 - drawing the design makes this a lot easier than ending up with random drill holes everywhere and bolting things on. Quick clamping systems which lock in place. Most attachments ( trommel ) are pre-thought and added to design. Quick leg changes in height should be simple as can be, keeping in mind that sand always fills and blocks most designs.

3 - has been a struggle to minimize the height of what to shovel into, so i want to have a sluice i could launch a shovel load at it at least 1 meter away onto a strong backplate, rather than lifting. If i have no choice i make a ramp from my tailings and rocks to walk up and out of my hole. Eventually the ramp is as tall as the sluice.

4 - cleanup im thinking the simple lock down and clamping riffle / mat design. One clamp to unlock / lock all layers. cleanup can be annoying as we struggle to unclamp, roll mats, lift sluice into a bucket..etc. a simple tray that clips onto the sluices end after mesh and riffles lifted, washed down with a spray of water from a garden hose sprayer. I tend not to mess with cleanup or even looking at my finds while digging. It all goes straight into a container with the days heavies collected.

5 - depends on the area

6 - banker should be structually build strong. I use thick alloy ( wish i could weld it ), around 3-5mm mostly and some thinner in sections of the sluice. A strong design in how the legs keep the system straight and sturdy by holding the top and bottom sluice as one. I now use a small clamp over the top of the sluice walls to hold its shape strong from water and rock forces pushing the walls outwards and making the sluice bend under matting.

7 - i try to keep it so the banker can be held one handed always, even when assembled but struggle at times with this. They are roughly the same weight as a walbanker and the option to carry it on your back is useful as well so keep that in mind. Ive thought of a transforming wheelburrow / sluice with a wheel or multiple wheels as well.

8 - always consider everyones designs. As jemba said, basically a stick in a cardboard box will catch gold, just make what suits you. Be careful of dodgy fast built sluices if you are buyingone. Check for upside down riffles.. sloppy tack welds leaving gaps everywhere and vortexing issues..too thin of material and the innability to modify freely..etc.

Be creative and try something new. Something i use that i dont see many members use, is matting and mesh in my top box. This isnt only useful for rubbing and breaking clays, but why not have an extra carpet on the top box? I catch gold up there as well as below.

Might be a bit of a mixed post ive done here but just trying to input from my perspective on things as ive dealt and seen most issues sluices have had and read most studies about designs and vortexes that others have done through the years. My first sluice was a 12" wide river sluice ( stollen now ) that had yukon style riffles on it. I needed 3 times the water to make the riffles even turn material and they just didnt happen. They would be great riffles on a steep, fast sluice for chunky gold though, but no good for gravity creek flow :lol:

1 - keep my sluices so they easily fit in my boot or anyone elses car with ease. Sluice extensions slide inside one another incrementing down in size.

2 - drawing the design makes this a lot easier than ending up with random drill holes everywhere and bolting things on. Quick clamping systems which lock in place. Most attachments ( trommel ) are pre-thought and added to design. Quick leg changes in height should be simple as can be, keeping in mind that sand always fills and blocks most designs.

3 - has been a struggle to minimize the height of what to shovel into, so i want to have a sluice i could launch a shovel load at it at least 1 meter away onto a strong backplate, rather than lifting. If i have no choice i make a ramp from my tailings and rocks to walk up and out of my hole. Eventually the ramp is as tall as the sluice.

4 - cleanup im thinking the simple lock down and clamping riffle / mat design. One clamp to unlock / lock all layers. cleanup can be annoying as we struggle to unclamp, roll mats, lift sluice into a bucket..etc. a simple tray that clips onto the sluices end after mesh and riffles lifted, washed down with a spray of water from a garden hose sprayer. I tend not to mess with cleanup or even looking at my finds while digging. It all goes straight into a container with the days heavies collected.

5 - depends on the area

6 - banker should be structually build strong. I use thick alloy ( wish i could weld it ), around 3-5mm mostly and some thinner in sections of the sluice. A strong design in how the legs keep the system straight and sturdy by holding the top and bottom sluice as one. I now use a small clamp over the top of the sluice walls to hold its shape strong from water and rock forces pushing the walls outwards and making the sluice bend under matting.

7 - i try to keep it so the banker can be held one handed always, even when assembled but struggle at times with this. They are roughly the same weight as a walbanker and the option to carry it on your back is useful as well so keep that in mind. Ive thought of a transforming wheelburrow / sluice with a wheel or multiple wheels as well.

8 - always consider everyones designs. As jemba said, basically a stick in a cardboard box will catch gold, just make what suits you. Be careful of dodgy fast built sluices if you are buyingone. Check for upside down riffles.. sloppy tack welds leaving gaps everywhere and vortexing issues..too thin of material and the innability to modify freely..etc.

Be creative and try something new. Something i use that i dont see many members use, is matting and mesh in my top box. This isnt only useful for rubbing and breaking clays, but why not have an extra carpet on the top box? I catch gold up there as well as below.

Might be a bit of a mixed post ive done here but just trying to input from my perspective on things as ive dealt and seen most issues sluices have had and read most studies about designs and vortexes that others have done through the years. My first sluice was a 12" wide river sluice ( stollen now ) that had yukon style riffles on it. I needed 3 times the water to make the riffles even turn material and they just didnt happen. They would be great riffles on a steep, fast sluice for chunky gold though, but no good for gravity creek flow :lol:

G

Guest

Mate that is a really good post thank you. cheers

Another little tip.

And I it is an acceptable thing by the powers that be,

.

When using a pump, Draw your water from the downstream side.

I was talking to an inspector once about the usage of a pump in a river and he said they prefer

to pump from down river up to where you are.

And I it is an acceptable thing by the powers that be,

.

When using a pump, Draw your water from the downstream side.

I was talking to an inspector once about the usage of a pump in a river and he said they prefer

to pump from down river up to where you are.

That's why should have your sluice run onto grass and rocks to filter, instead of feeding it straight back into the water supply. The silts from your sluice wouldnt do much damage anyway if there's running water

Sometimes you are hemmed in and you just can't do that .. I process my gold lines where they are and have never had a ranger say I couldn't do that ( Vic) but they do get grumpy with people testing layers in the banks ? As they should ! So until instructed first hand I will do as I've always done , remember take the water to the dirt it's a lot easier.

G

Guest

Yes indeed guys working within the rules, even though we may not agree with them we must obey them. Good point fellows. Cheers and thanks

G

Guest

In regards to foot valves it is a very good idea to never pan off over them or walk around in the water where they are placed while the are working. They will suck up fine silt which can chew out the pumps seal real quick.

A little off topic and I will remove this post if desired.

Make the best with what you have and if you are going to do a stuff up, Make sure you do it properly.

https://www.prospectingaustralia.com/forum/viewtopic.php?id=12169

Make the best with what you have and if you are going to do a stuff up, Make sure you do it properly.

https://www.prospectingaustralia.com/forum/viewtopic.php?id=12169

Tater said:Sometimes you are hemmed in and you just can't do that .. I process my gold lines where they are and have never had a ranger say I couldn't do that ( Vic) but they do get grumpy with people testing layers in the banks ? As they should ! So until instructed first hand I will do as I've always done , remember take the water to the dirt it's a lot easier.

7 - i try to keep it so the banker can be held one handed always, even when assembled but struggle at times with this. They are roughly the same weight as a walbanker and the option to carry it on your back is useful as well so keep that in mind. Ive thought of a transforming wheelburrow / sluice with a wheel or multiple wheels as well.

I've recently mounted my banker to a modified golf bag cart. Folds down to fit fit in the boot and some holes in the mounting for the handle provide the majority of height adjustment. does need stronger wheels or at least new tyres though. Done this way you can strap smaller pumps, layflat, picks etc. to the unit for hiking in.I'll try and remember to take some pics in the next couple of days.

modifications to the cart were pretty minimal, a few holes for height adjustment and a couple of pieces of angle iron to bolt the banker on.

I've recently mounted my banker to a modified golf bag cart. Folds down to fit fit in the boot and some holes in the mounting for the handle provide the majority of height adjustment. does need stronger wheels or at least new tyres though. Done this way you can strap smaller pumps, layflat, picks etc. to the unit for hiking in.I'll try and remember to take some pics in the next couple of days.

modifications to the cart were pretty minimal, a few holes for height adjustment and a couple of pieces of angle iron to bolt the banker on.

What I got pulled up for was taking drums of wash down the road to process !!! You are allowed to process on site and take away cons ( minerals) do not remove dirt and gravel from where it is ! So says the ranger ! Vic again , so to all those who prospect in Vic do not post on a public forum that you are taking dirt to wash at home ! Other states I don't know about . Now and again you might test a layer in the bank ,if you do don't put it in a post on a public forum . I know this because I was head smacked over something I posted ,it was legal and checked , but the greens used it as a reason to vilify prospectors at a recent inquiry. IMO do not put things on a public forum that you wouldn't email to your granny! Lol,

G

Guest

bend said:7 - i try to keep it so the banker can be held one handed always, even when assembled but struggle at times with this. They are roughly the same weight as a walbanker and the option to carry it on your back is useful as well so keep that in mind. Ive thought of a transforming wheelburrow / sluice with a wheel or multiple wheels as well.

I've recently mounted my banker to a modified golf bag cart. Folds down to fit fit in the boot and some holes in the mounting for the handle provide the majority of height adjustment. does need stronger wheels or at least new tyres though. Done this way you can strap smaller pumps, layflat, picks etc. to the unit for hiking in.I'll try and remember to take some pics in the next couple of days.

modifications to the cart were pretty minimal, a few holes for height adjustment and a couple of pieces of angle iron to bolt the banker on.

Yep I understand where your coming from and the idea is very good thanks for posting. For those who are unable to make their own gear due to varying reasons. There are so many bankers on the net it would take a year to wade through them all. That is where a good forum with experienced members comes into play for you. Once a bit of gear gets your eye, all you have to do is ask the question and sure as tomorrow will come someone will respond. This can and will save you big bucks at no cost other than time. Do not rush into a sale without research on the item.

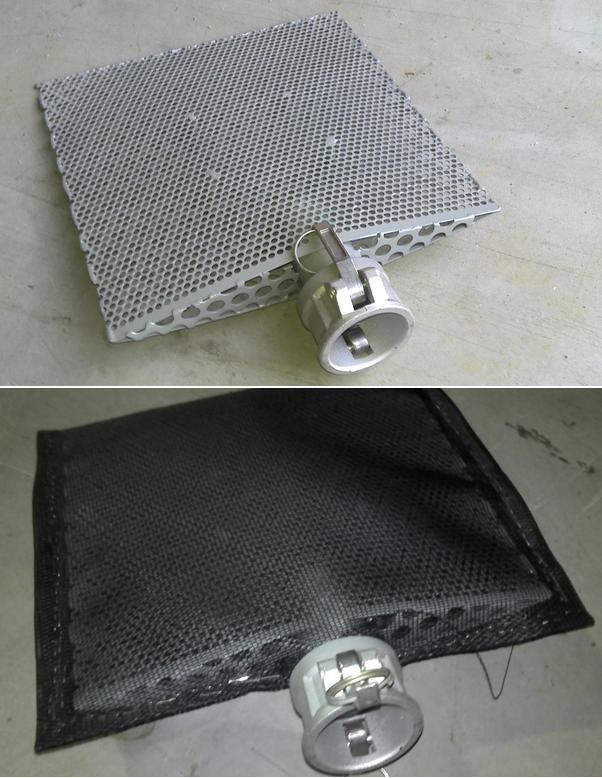

AtomRat said:Ok..ive got a question while where sort of on pumps. Sometimes ive seen at the inlet the water supply can tend to swirl and make a vortex down to the inlet. Even if its well under the water and deep. Is this eddy currents causing it say if were in a creek?

If the water IS low and you have this problem, whats the best solution? Im guessing a guard over the top side of the mesh?

sorry for reposting this again ...

the shallow water solution .

large surface area , mosquito mesh all over, 4mm perf mesh on the bottom ( muddy side ) and 12 mm perf mesh facing to the top.

Absolutely awesome headsup

Similar threads

- Replies

- 18

- Views

- 2K

- Replies

- 0

- Views

- 279

- Replies

- 5

- Views

- 423

- Replies

- 5

- Views

- 2K