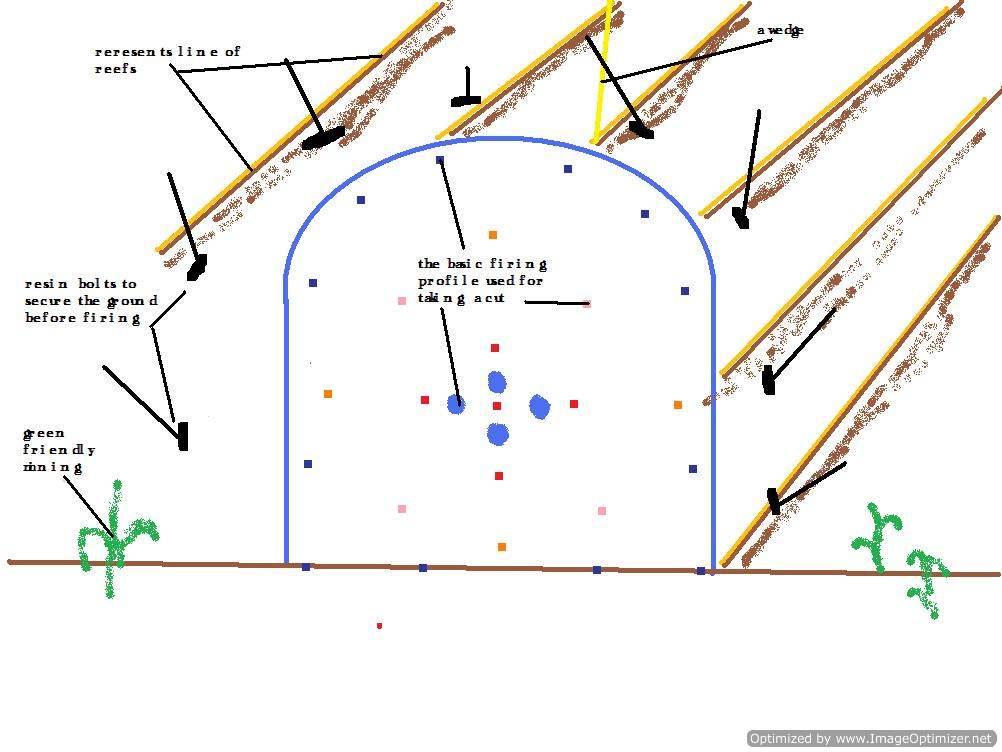

Interested in taking a "cut" running some down holes for a "shaft sink", need to take a "part face" "inclining" 'declining" "portal" or "adit", all used in mining small or large scale.

So you have a wee mining lease, how can i go about knocking some rocks about without using ANFO, POWER GEL, TNT, DETS, EMULSION, simple "NON EXPLOSIVE CRACKING AGENTS", used in quarries and mining this product expands in drilled holes to crack the rock.

Its non explosive, environmentally safe, and whisper quiet.

So lets start with you have a small hard rock mining lease approved and your going to kick off with a shaft sink, working on the theory you have hit bedrock at 2 feet.

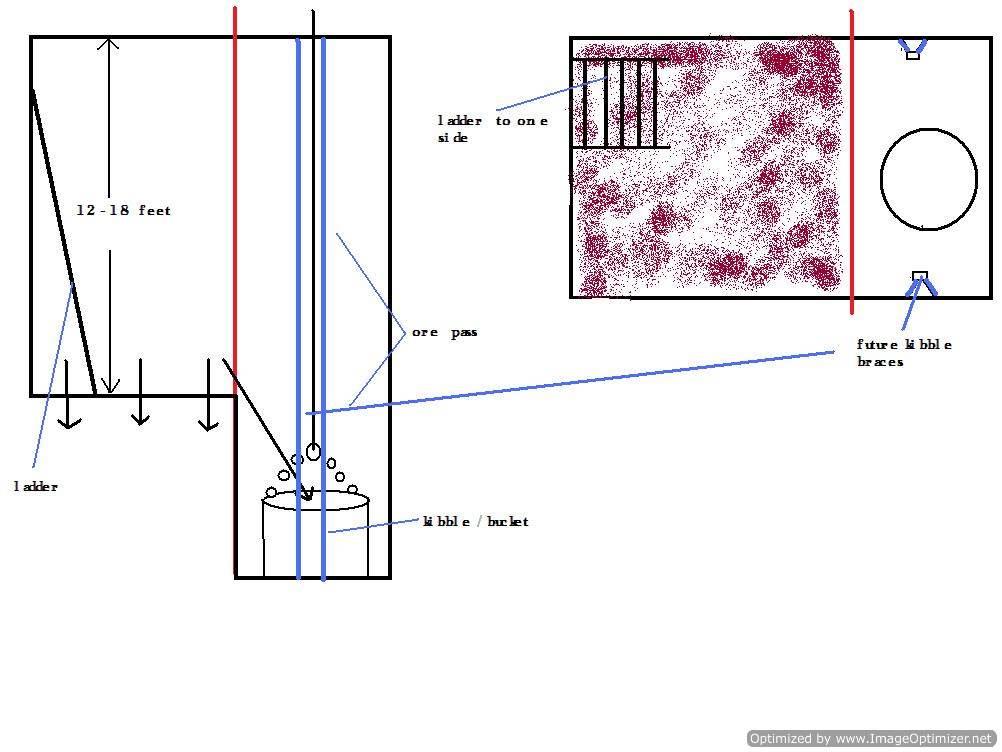

Firstly you need to bore holes, now were on a tight budget so a 100cfm commpressor and a SIG29 rock drill are out of the question, settle for a large rotary/demo drill normally you can pick these up for about 1k with 900mm x 30mm drill bits, firstly mark out your shaft size (keeping in mind you will need a section for an ore/waste pass)

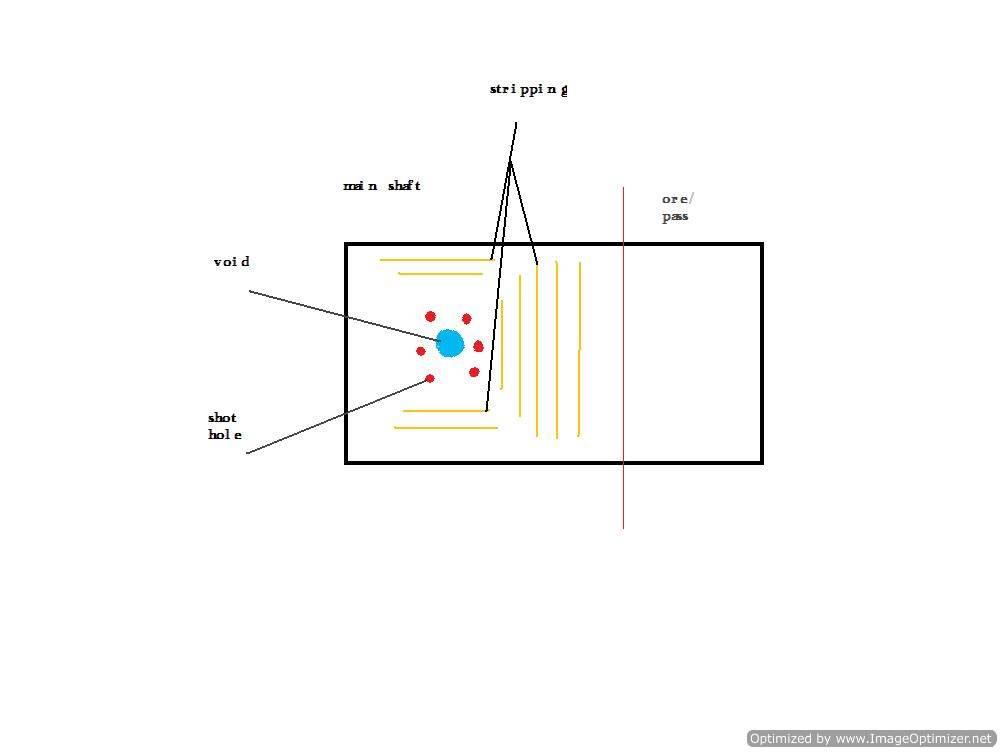

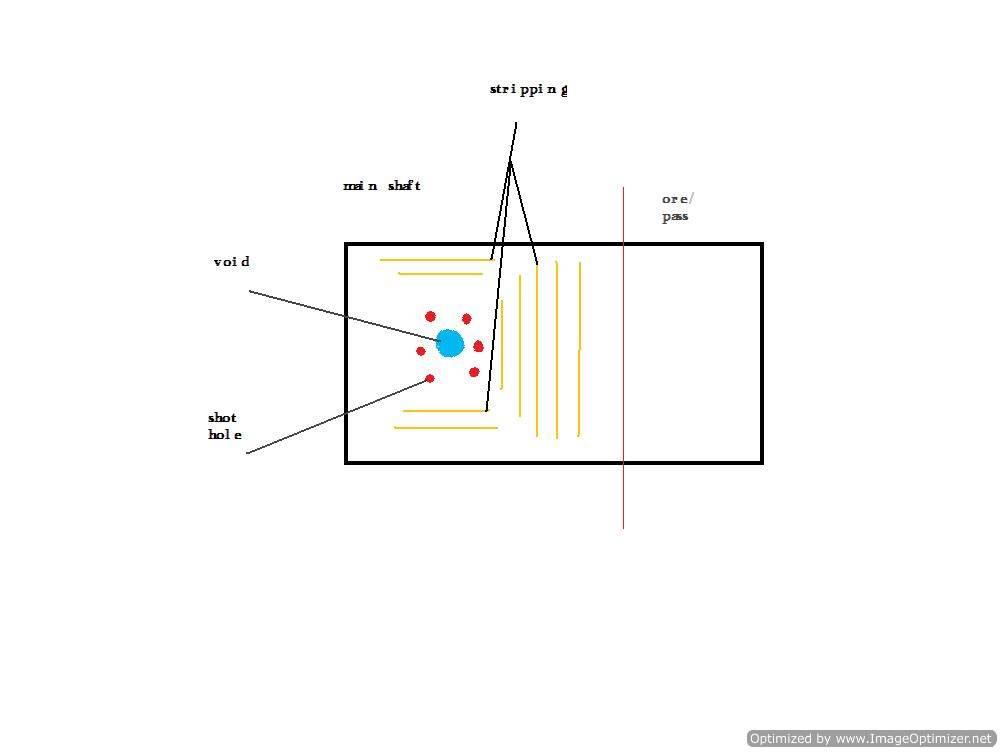

From the pic below you can see the blue hole which is referenced as void, this is the most critical part of any cut, firing, whenever you try to remove rock in its solid state you need an area for the rock to move to, hence the void, this can be achieved by boring holes in close proximity to each other and jack hammering out the centre (note: the hole dose not have to be neat or round it just needs to be a hole)

The red holes around the void are classed as "shot" holes, these when loaded with non explosive cracking agent will break into the void if you keep in mind that everything tries to take the easy way out, the point of least resistance, you will have no trouble in getting your head around how to break rock up.

The yellow lines are classed as stripping, this can be done by boring holes in similar fashion to your shot holes, or simply slicing the rock with a jack hammer, once again breaking the dirt into the area of least resistance, that being the void.

The red lines dsignates your ore/waste pass, we will get more descriptive on that later, you dont need to do anything here until your at a depth of head height, so strip out the rock to your desired width of the shaft.

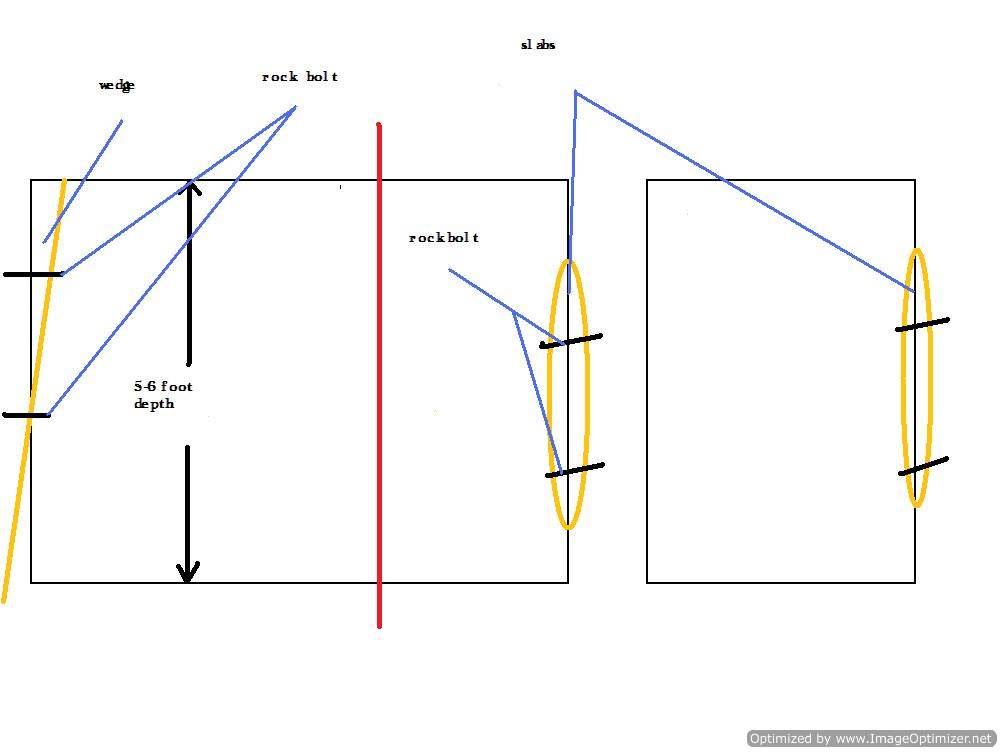

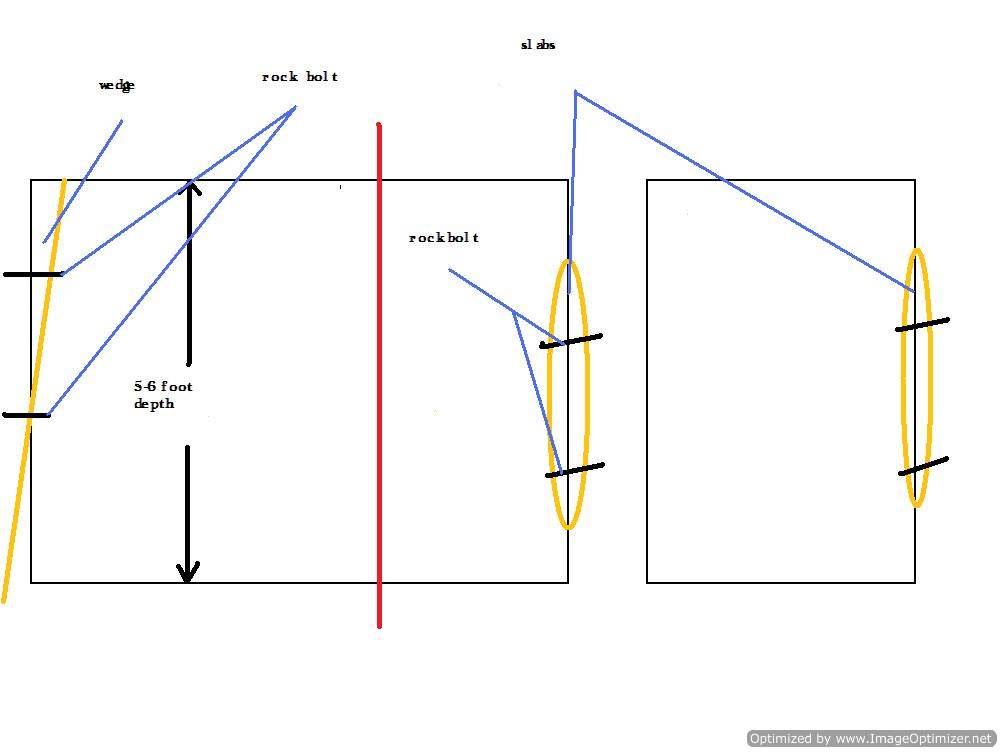

So now were at roughly 5-6 foot level, and we have hit a few snags, eg wedges and slabs, these suckers can and are lethal, to remove these can break open the shaft to a size that can and will compromise the integrity of our shaft, so by installing rock bolts we essentially are locking these rocks into position.

These can be purchased but are expensive, but are a necessity, approach a local mine about purchasing these, they have them in bundles so they will not be hard to acquire.

These are called "resin bolts" and "split sets", i would recomend the resin bolts they are a high tensile threaded bar that uses a two part epoxy resin to set at the rear of the hole, once the resin has "turned" the shear pin in the nut can be cracked and you can then tension the nut to pull the slab or wedge up tight locking it into place, note: if you do tension these resin bolts DO NOT over tension, by over tensioning you can compromise the effectivness of that particular ground support, the bolts have plates on the back of them, if the ground decides to move the plate will 'give" by this i mean bend, hence now loading up the bolt with weight and a perfect tell tale is a bent plate.

So you have a wee mining lease, how can i go about knocking some rocks about without using ANFO, POWER GEL, TNT, DETS, EMULSION, simple "NON EXPLOSIVE CRACKING AGENTS", used in quarries and mining this product expands in drilled holes to crack the rock.

Its non explosive, environmentally safe, and whisper quiet.

So lets start with you have a small hard rock mining lease approved and your going to kick off with a shaft sink, working on the theory you have hit bedrock at 2 feet.

Firstly you need to bore holes, now were on a tight budget so a 100cfm commpressor and a SIG29 rock drill are out of the question, settle for a large rotary/demo drill normally you can pick these up for about 1k with 900mm x 30mm drill bits, firstly mark out your shaft size (keeping in mind you will need a section for an ore/waste pass)

From the pic below you can see the blue hole which is referenced as void, this is the most critical part of any cut, firing, whenever you try to remove rock in its solid state you need an area for the rock to move to, hence the void, this can be achieved by boring holes in close proximity to each other and jack hammering out the centre (note: the hole dose not have to be neat or round it just needs to be a hole)

The red holes around the void are classed as "shot" holes, these when loaded with non explosive cracking agent will break into the void if you keep in mind that everything tries to take the easy way out, the point of least resistance, you will have no trouble in getting your head around how to break rock up.

The yellow lines are classed as stripping, this can be done by boring holes in similar fashion to your shot holes, or simply slicing the rock with a jack hammer, once again breaking the dirt into the area of least resistance, that being the void.

The red lines dsignates your ore/waste pass, we will get more descriptive on that later, you dont need to do anything here until your at a depth of head height, so strip out the rock to your desired width of the shaft.

So now were at roughly 5-6 foot level, and we have hit a few snags, eg wedges and slabs, these suckers can and are lethal, to remove these can break open the shaft to a size that can and will compromise the integrity of our shaft, so by installing rock bolts we essentially are locking these rocks into position.

These can be purchased but are expensive, but are a necessity, approach a local mine about purchasing these, they have them in bundles so they will not be hard to acquire.

These are called "resin bolts" and "split sets", i would recomend the resin bolts they are a high tensile threaded bar that uses a two part epoxy resin to set at the rear of the hole, once the resin has "turned" the shear pin in the nut can be cracked and you can then tension the nut to pull the slab or wedge up tight locking it into place, note: if you do tension these resin bolts DO NOT over tension, by over tensioning you can compromise the effectivness of that particular ground support, the bolts have plates on the back of them, if the ground decides to move the plate will 'give" by this i mean bend, hence now loading up the bolt with weight and a perfect tell tale is a bent plate.