aushunter

Brad Welch

- Joined

- Feb 15, 2013

- Messages

- 645

- Reaction score

- 525

Hey Lads,

Been busy lately, still with the reno, scored a new job in the Plastics industries and yes plastic welders are a reality.

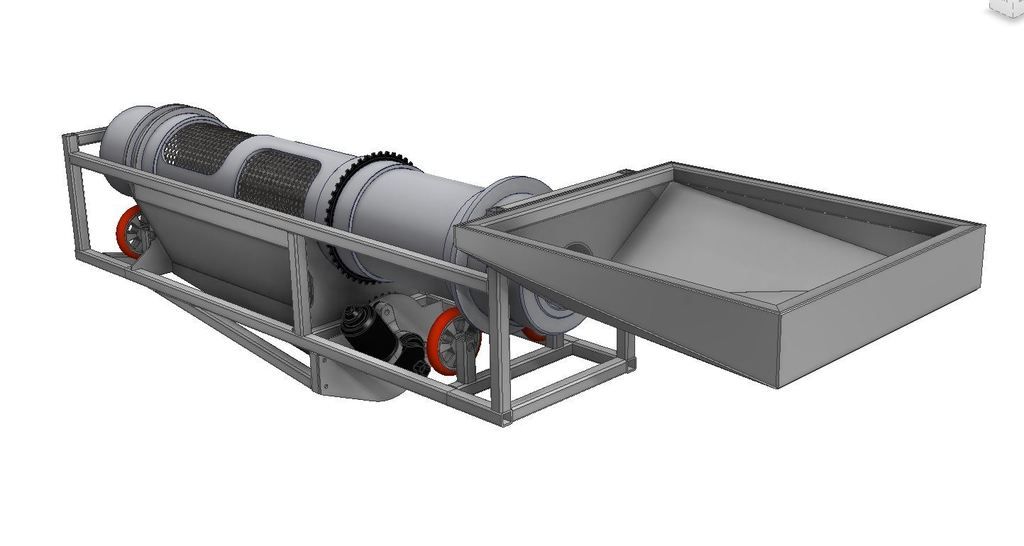

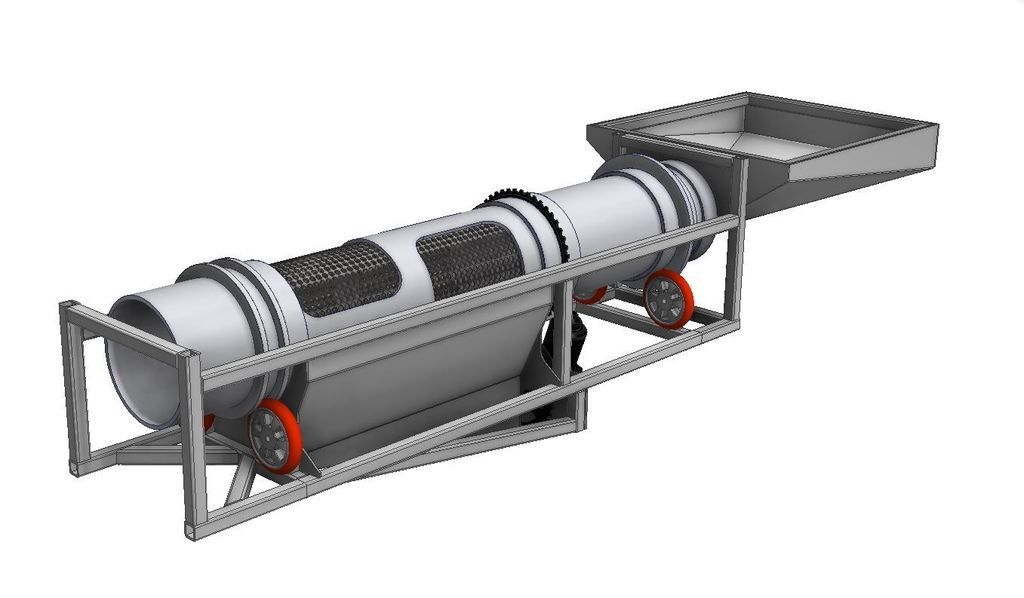

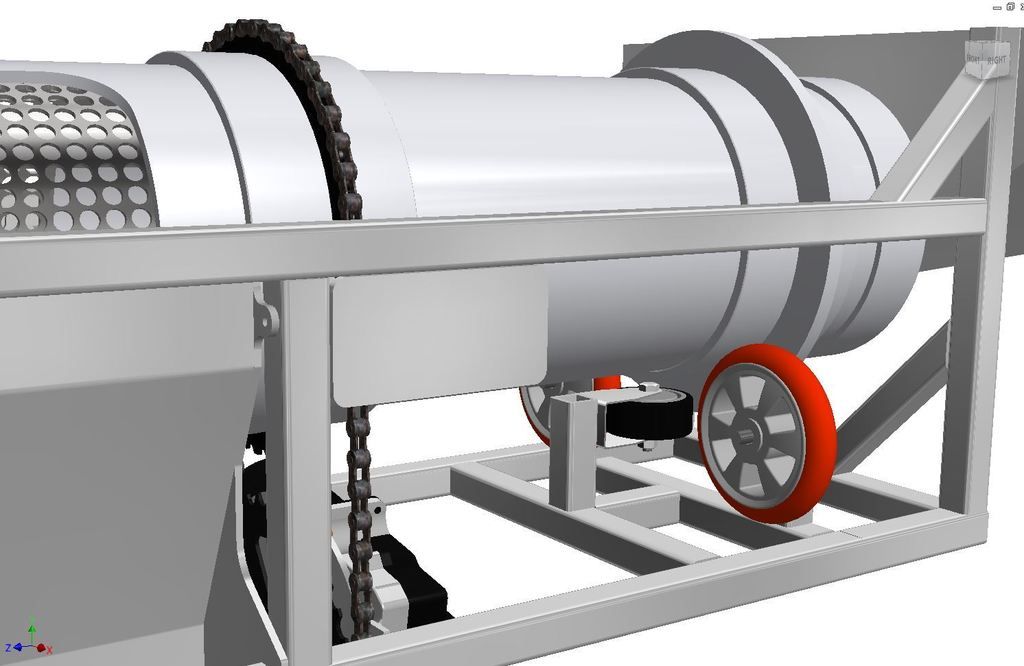

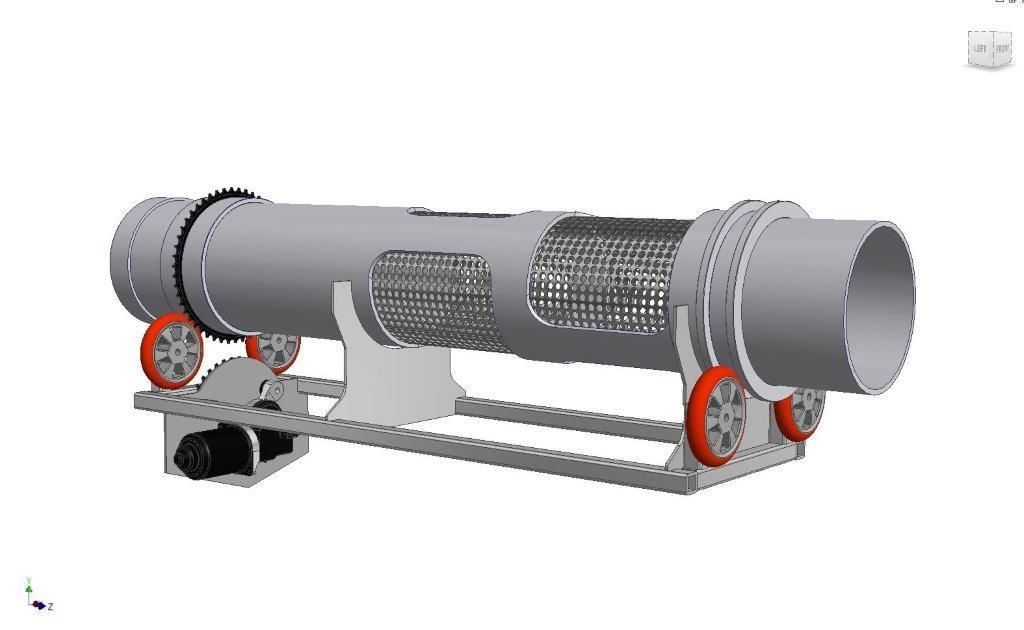

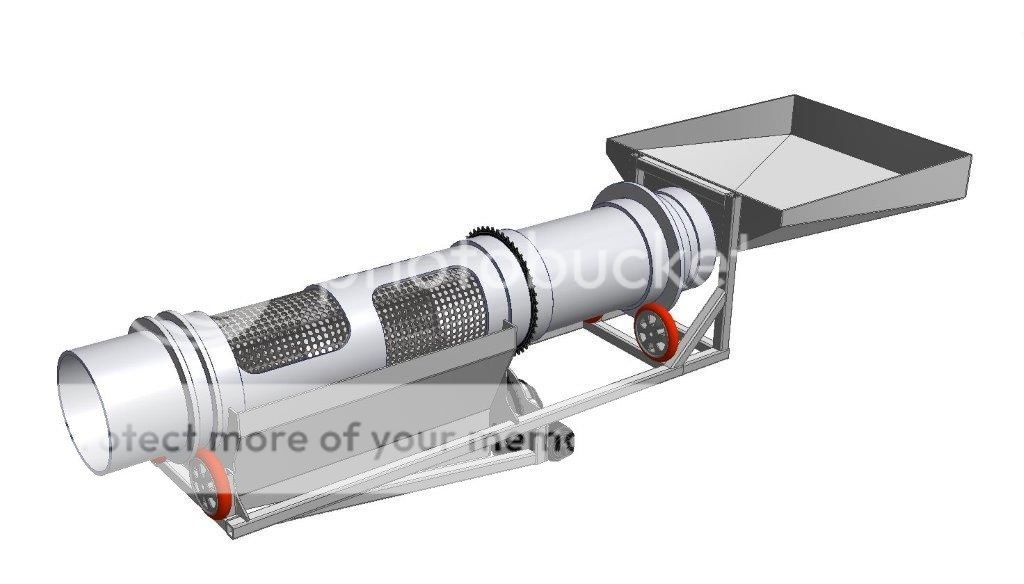

And during my little time I have when wifey is out shopping I am slowly building my little 6" poly trammel that is run by a Toyota Windscreen Wiper Motor which drives the main Barrel via pushbike chain.

I have the Barrel pretty much finished, the motor and chain and Sprockets, now I am in the stages of getting together a simple enough frame design that works using 20mm gal hollow bar. Well I hear a lot thinkin out there why not Alloy, well I have that kicking around the house so to save cost I will use that instead.

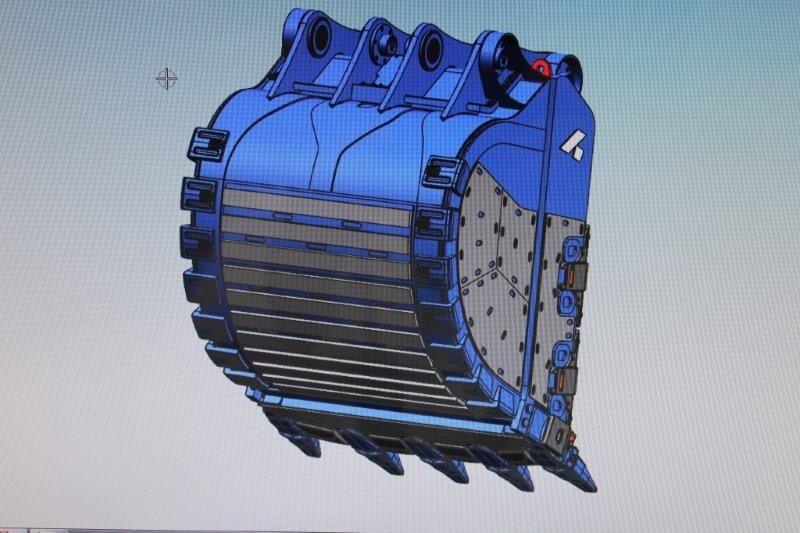

The perforated grill came from a range hood thrown out in a bin when I was working at Masters a month or two ago.

A smaller Sprocket from the same pushbike will be attached to the Windscreen wiper motor

Looking Down the Barrel

The main Sprocket from the Pushie just fits nicely.

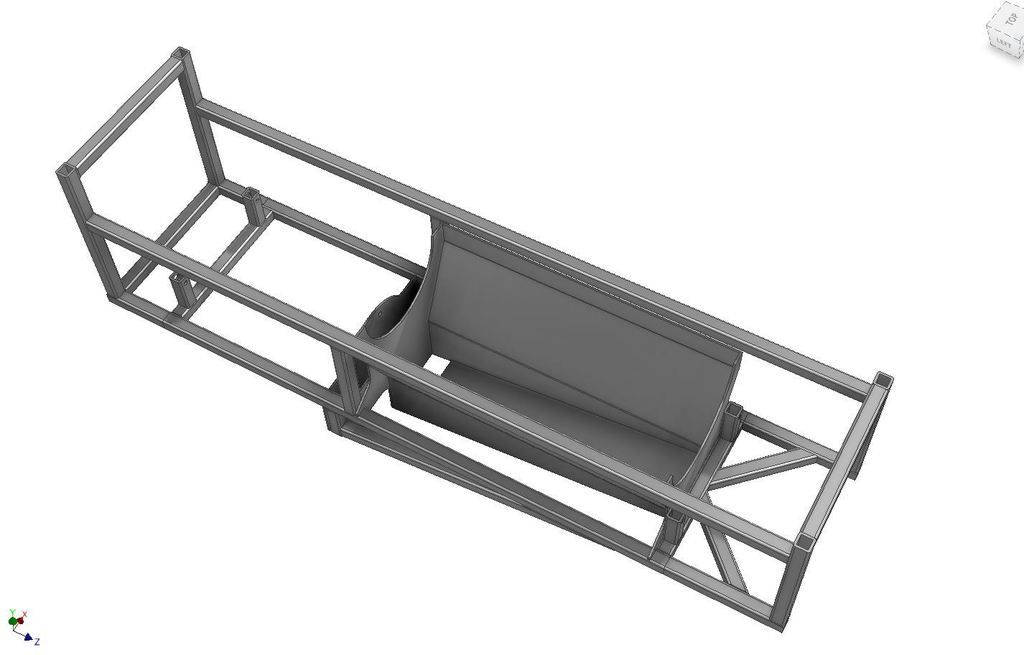

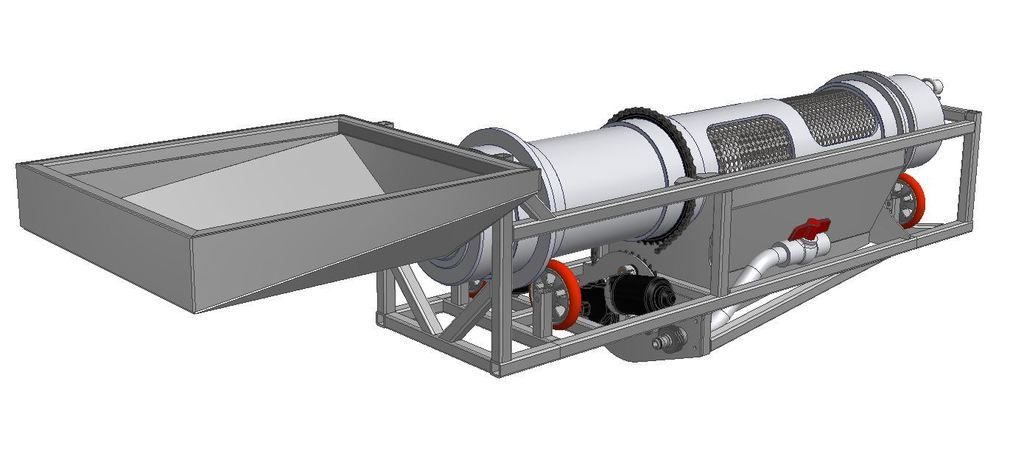

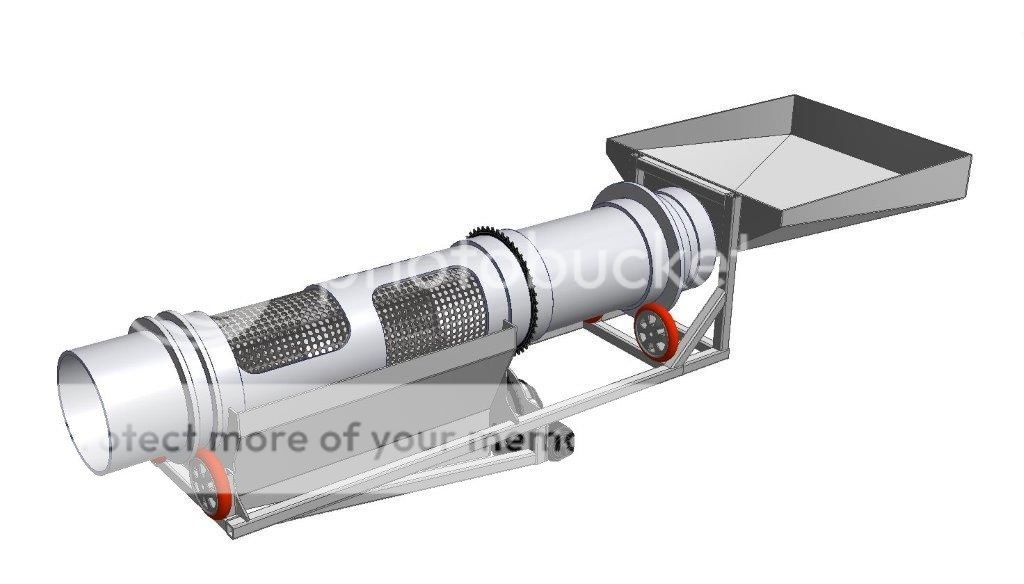

My original design. Not quite right.

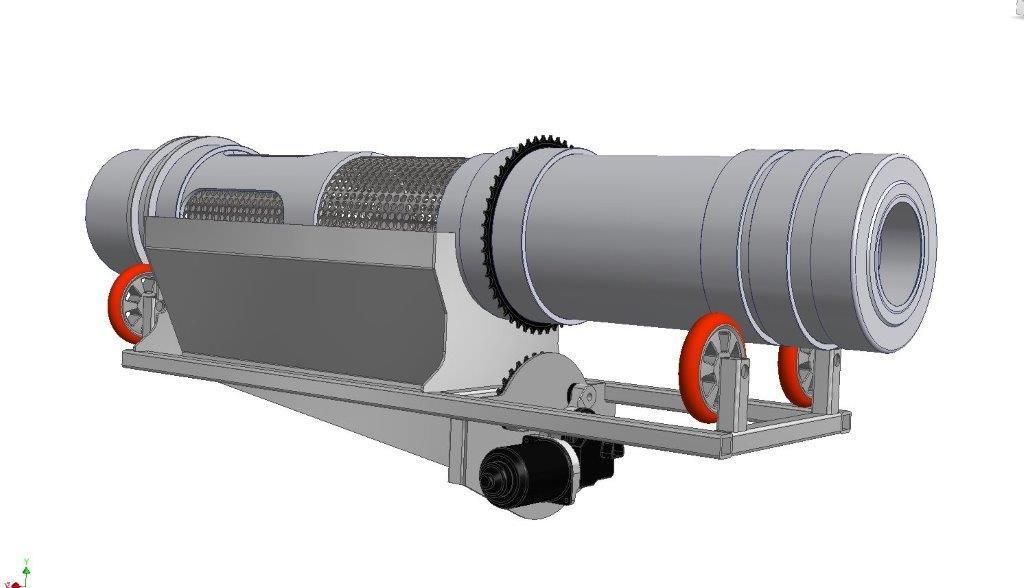

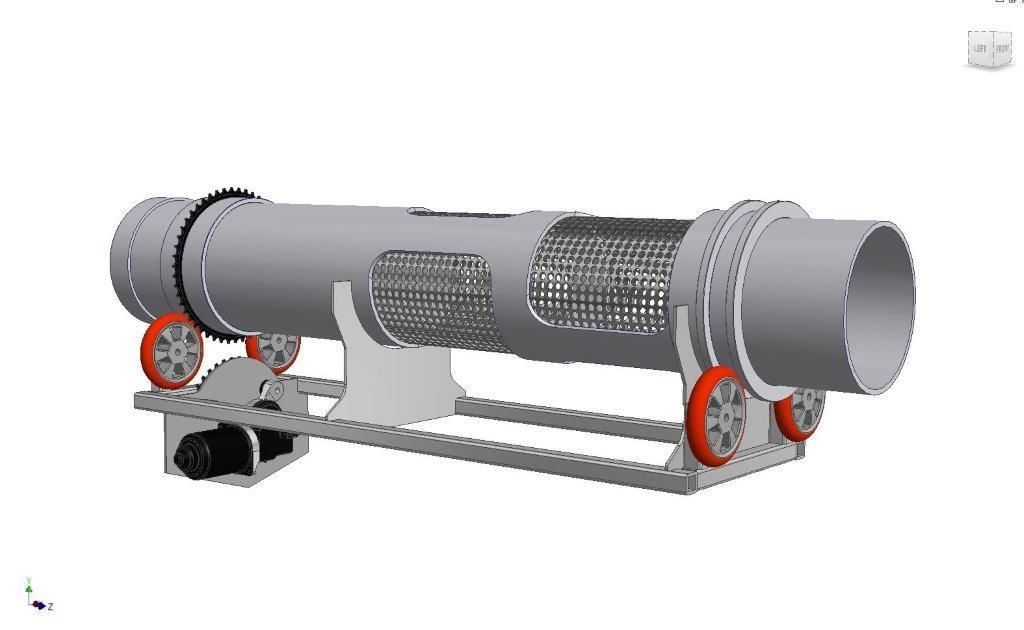

Just another view

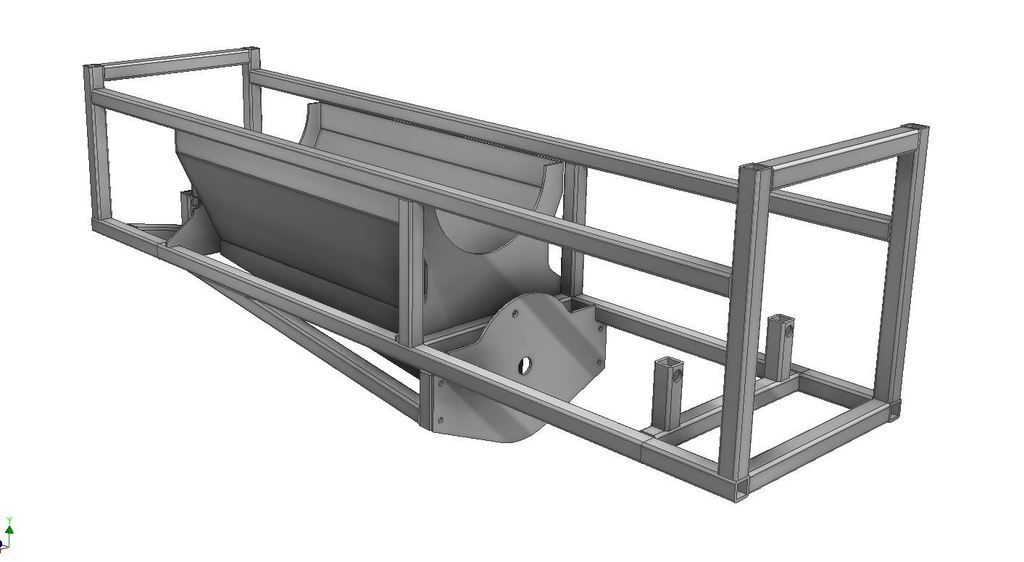

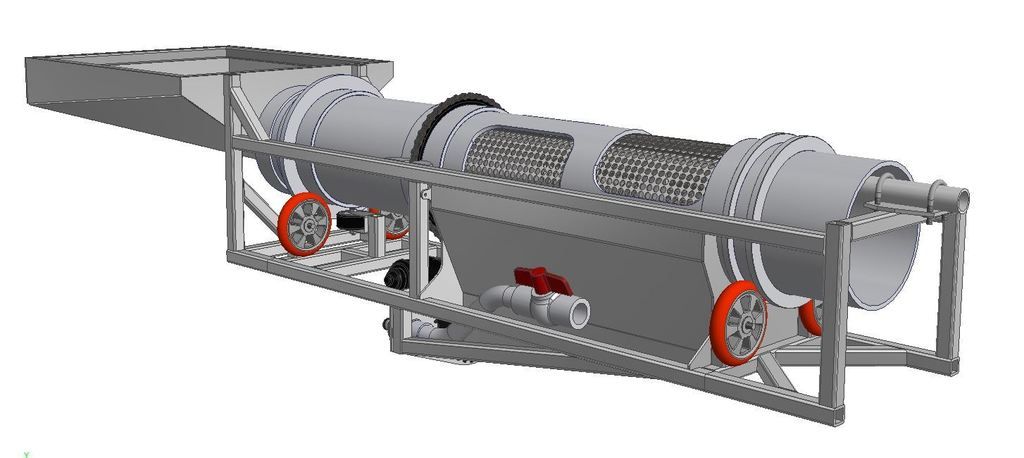

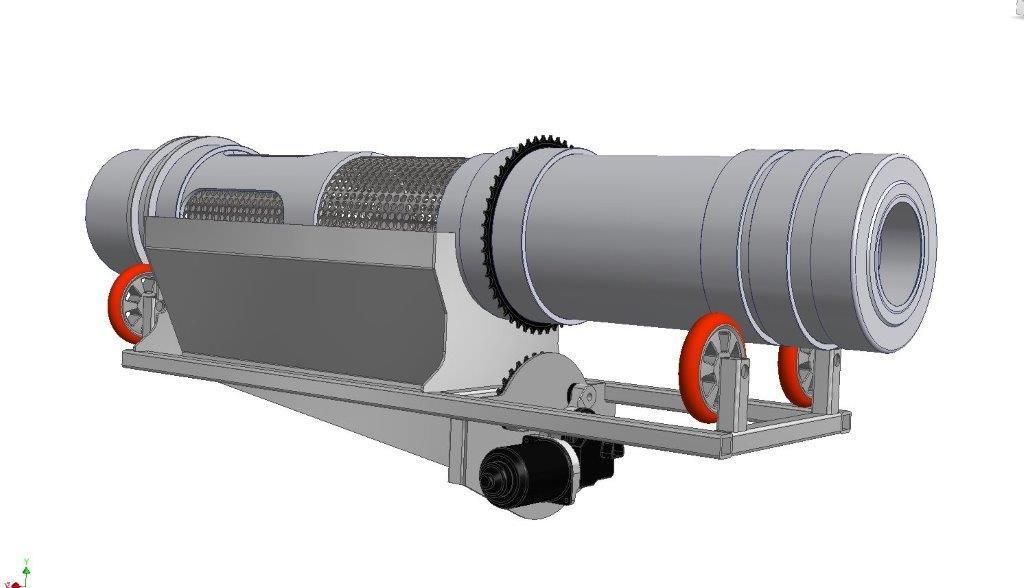

So I tried another way, looking good.

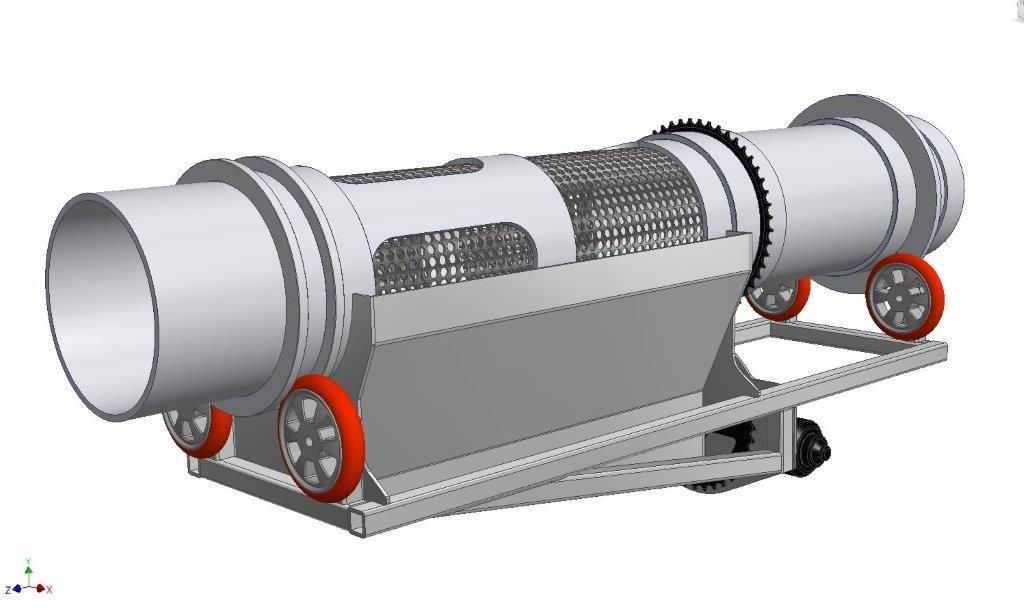

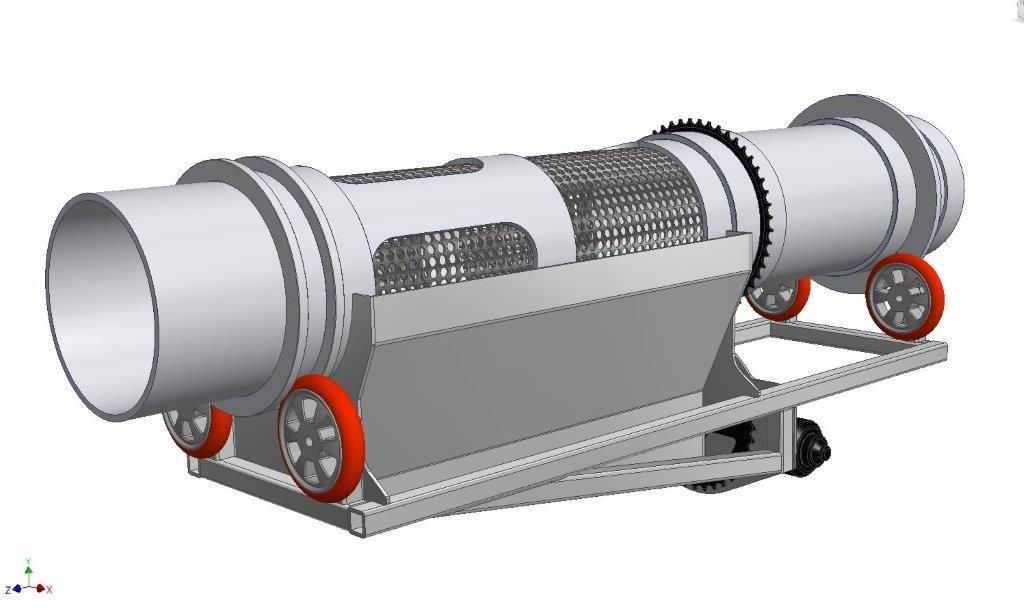

Starting on the Shute/grizzly

I hope the boys don't mind me pinching there scooter wheels, runs really smooth too.

I still have muck around with it yet but I will get there no doubt.

Cheers

Brad....

Been busy lately, still with the reno, scored a new job in the Plastics industries and yes plastic welders are a reality.

And during my little time I have when wifey is out shopping I am slowly building my little 6" poly trammel that is run by a Toyota Windscreen Wiper Motor which drives the main Barrel via pushbike chain.

I have the Barrel pretty much finished, the motor and chain and Sprockets, now I am in the stages of getting together a simple enough frame design that works using 20mm gal hollow bar. Well I hear a lot thinkin out there why not Alloy, well I have that kicking around the house so to save cost I will use that instead.

The perforated grill came from a range hood thrown out in a bin when I was working at Masters a month or two ago.

A smaller Sprocket from the same pushbike will be attached to the Windscreen wiper motor

Looking Down the Barrel

The main Sprocket from the Pushie just fits nicely.

My original design. Not quite right.

Just another view

So I tried another way, looking good.

Starting on the Shute/grizzly

I hope the boys don't mind me pinching there scooter wheels, runs really smooth too.

I still have muck around with it yet but I will get there no doubt.

Cheers

Brad....