waiting with bated breath  ickshovel: :gemstone:

ickshovel: :gemstone:  ower:

ower:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Actually Building the Machine!

- Thread starter Nena

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Me too yes it is still a function i want to have in the machine to automatic change the laps!

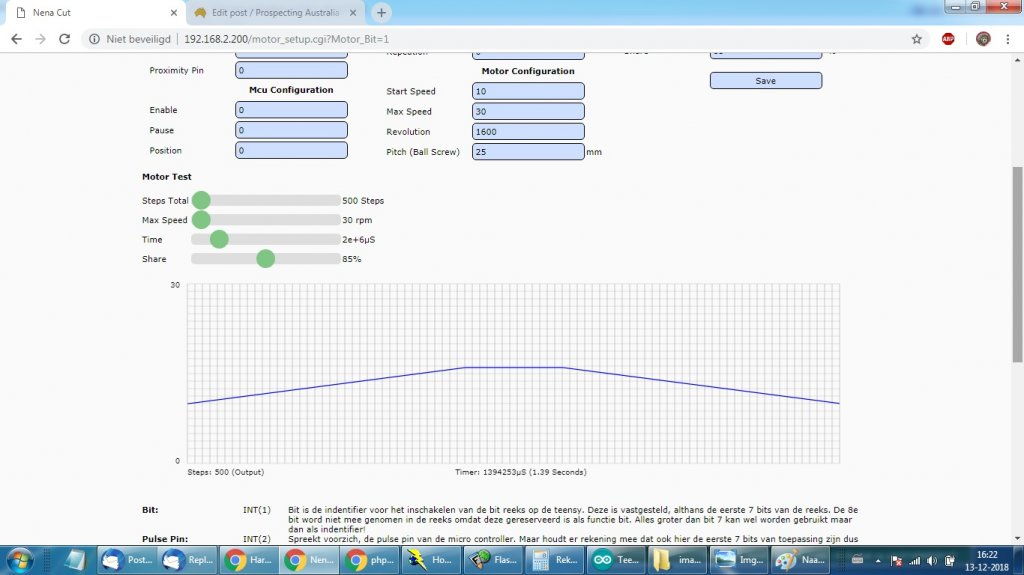

First i need to solder de teensy mcu for programming the beast :- ) Still have a lot to program...

First i need to solder de teensy mcu for programming the beast :- ) Still have a lot to program...

:100: :gemstone: :koala:

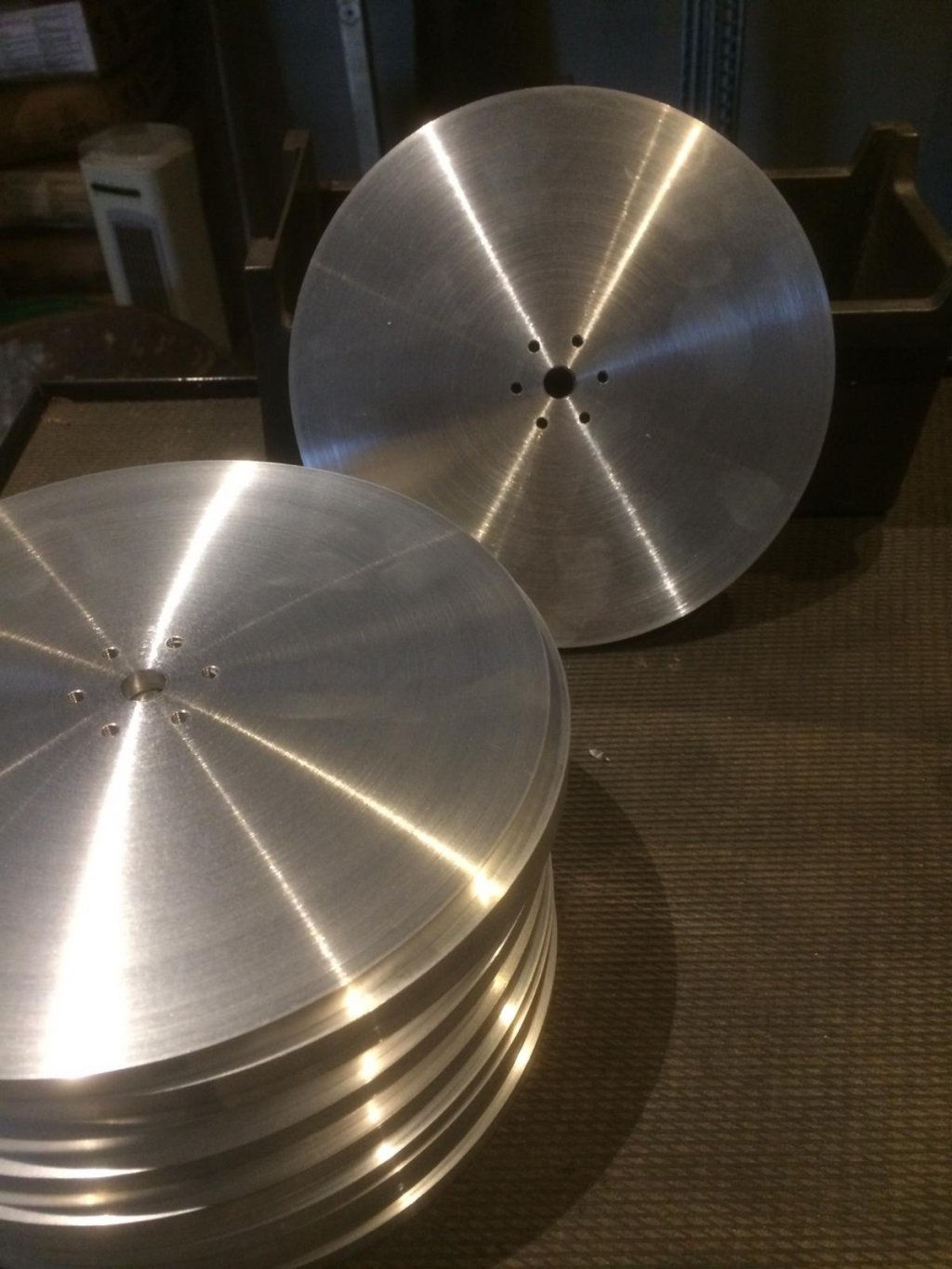

Whoohoo, the underlayment laps are almost done! Hope to see them soon!!! :heart:

Christian

Hi,

Ill first going to use those for china laps sintered laps are around 1000 euro's each... big? 200mm in diameter and 16 in total for the lap changer :- ) im going to glue the cheap china laps for test onto the underlayment laps. And if i need to replace them ill use acetone to remove them off the base laps.

Greets,

Christian

Ill first going to use those for china laps sintered laps are around 1000 euro's each... big? 200mm in diameter and 16 in total for the lap changer :- ) im going to glue the cheap china laps for test onto the underlayment laps. And if i need to replace them ill use acetone to remove them off the base laps.

Greets,

Christian

Those china laps are 10-20 euro each?! So these ill use for test :- ) they work, they arent that greath but good inaf for testing. Sintered laps are too expensive but works a lifetime but dont have 1000 euro's for each lap  so ill use the cheap ones for testing and some laps from BATT laps. But also those costs around 200-300 usd each.

so ill use the cheap ones for testing and some laps from BATT laps. But also those costs around 200-300 usd each.

I can glue them together under preasure so dont think the runout will be that high. But testing should tell

I can glue them together under preasure so dont think the runout will be that high. But testing should tell

Yes they are cheap and thin.

Batt laps are good though. But for testing you will only need one or two laps anyway. Just for checking the machine and the programming.

Hope it will work out with the glueing of the laps.

When are you going to start with the tests?

Batt laps are good though. But for testing you will only need one or two laps anyway. Just for checking the machine and the programming.

Hope it will work out with the glueing of the laps.

When are you going to start with the tests?

When im done with the motors, its still a pain in the *** but im almost done and did some promesing tests. Im almost there now, software is time consuming work so it can take a few weeks to a month  but mayby i can fix it in a few day's

but mayby i can fix it in a few day's  hahaha

hahaha

I have a local made 10 inch flat lap and the chinese thin plates are glued to pvc magnet sheet and are easy to remove

ray :money:

ray :money:

Thats very clever Gilly.

Mackka

Mackka

Ya thats a good tip!!! Doesnt work on aluminium lol but thats a good solution for those laps! Ill glue them directly to the base lap.

Top!

Top!

Not my brain storm,, The guy that sells and makes saws,grinders and laps in central QLD coast. Clive, been makin stuff for years.

My flat lap is a bench drill press with the drill head turned upside down and a skillett lid for a water carrier.

ray :100: erfect: :100:

erfect: :100:

My flat lap is a bench drill press with the drill head turned upside down and a skillett lid for a water carrier.

ray :100:

Necessity the Mother of Invention

Well done Gilly

Mackka :Y: :Y: :Y:

Well done Gilly

Mackka :Y: :Y: :Y:

Mackka said:Necessity the Mother of Invention

Well done Gilly

Mackka :Y: :Y: :Y:

I will put up a pic tomorrow of my 'Victa' Flat Lap Machine just for you Mackka... Yes its made from a Lawnmower...

I have an old book with lots of Plans on 'Homemade Lapidary' gear... :Y:

LW....

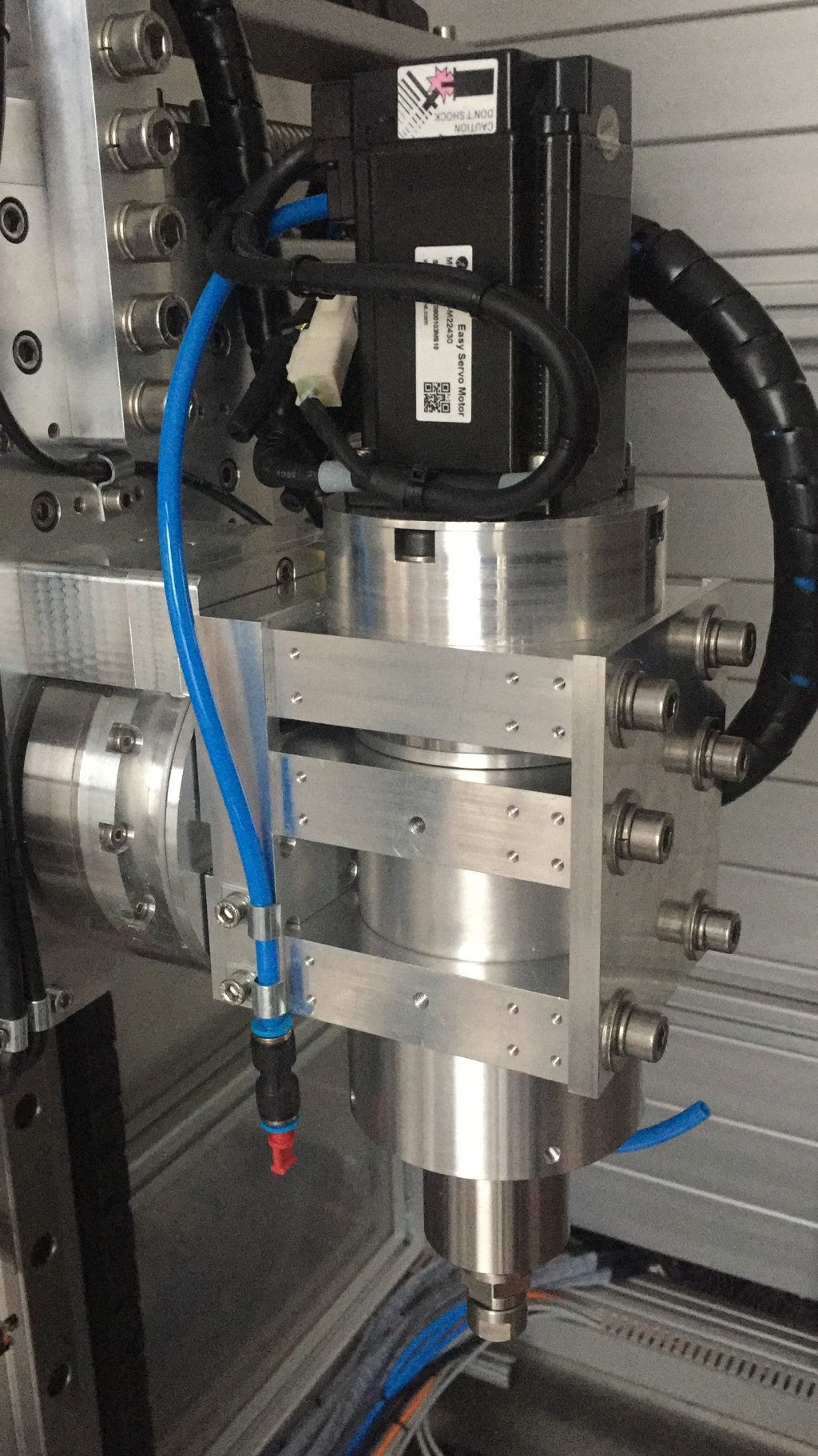

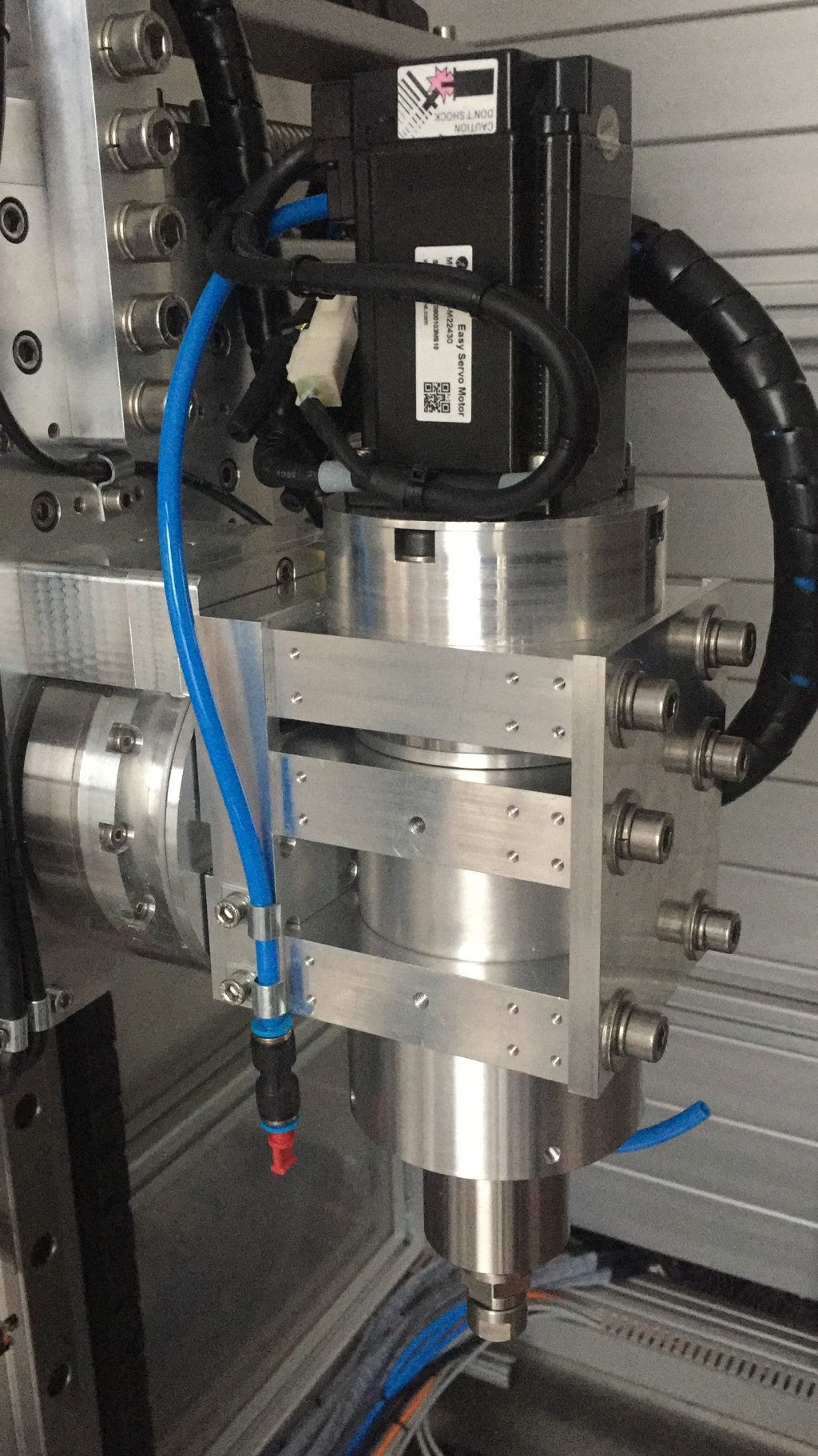

Yes! My milling work is done

Soon the rest i hope

i hope

Soon the rest

Coming along nicely Nena.... Wish I had access to that sort of gear to make things...

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 1

- Views

- 1K

- Replies

- 9

- Views

- 1K