Syndyne

Shaun Galman

Hi all,

As this had some interest over on Matt22's DIY Hand Dredge thread, I thought I would give it it's own thread to be a bit more concise on changes and idea's that may come.

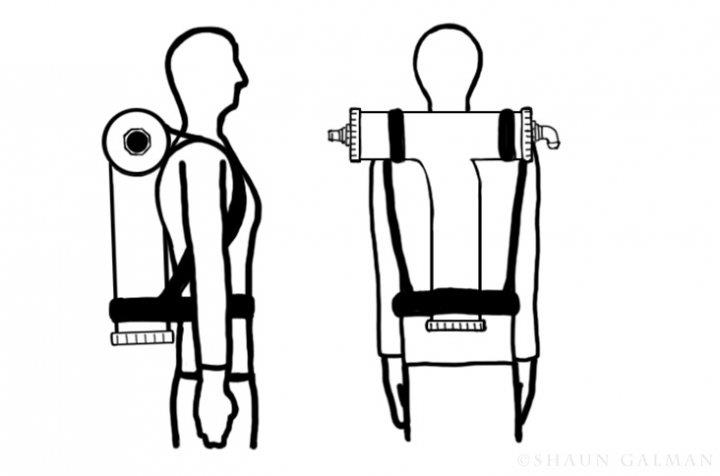

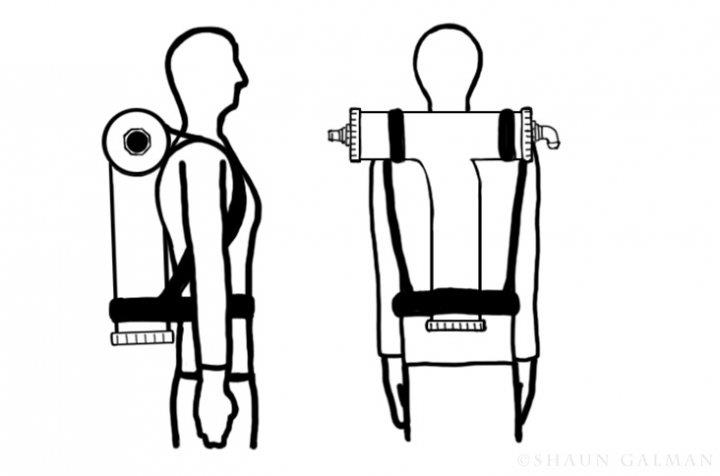

The basics of this bilge pump design had come from a previous one I found many years ago and I believe there are one or two similar still around on the older US prospecting forums. However saying that, I have yet to see or find a good backpack mounted design like this. The basic parts are in the first photo -minus the actual strapping section that I still need to find for the mounting application. It can still be used on the ground as we did with the first design, but not as portable that way.

These 1" Jabsco manual bilge pumps are some serious business! Purchased from BIAS Boating and rated at 100L/min -which I feel is pretty close to real world use as it gives a squirt that goes out anywhere between 12-15feet every second or so. In the field we found that once primed it only needed a few good pumps to create tremendous suction in the PVC unit. The reason for the PVC is that on initial testing we thought of using a drum for strength so I set it up with a thick walled brewers keg (rated for high compression) and after priming and giving a few good pumps the keg just imploded and completely destroyed itself. It did this on a second try with a 10ltr (20Gallon) steel oil drum (with the clip locking lid) . This was a blessing in a way as we also realised the weight of a drum full of dirt and water was far too much to handle anyway so we then scaled it down somewhat.

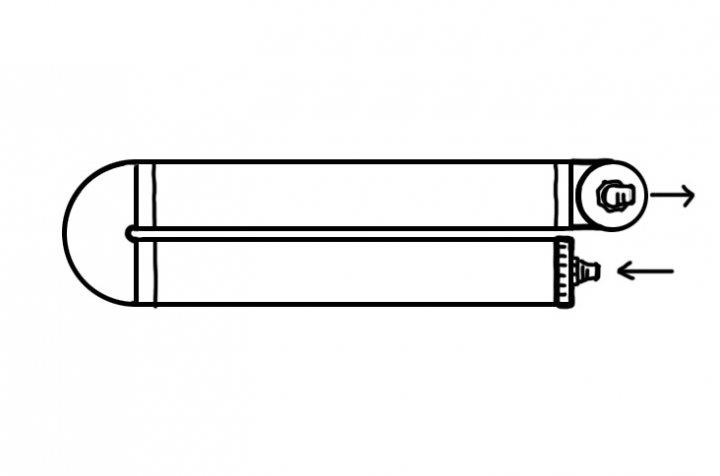

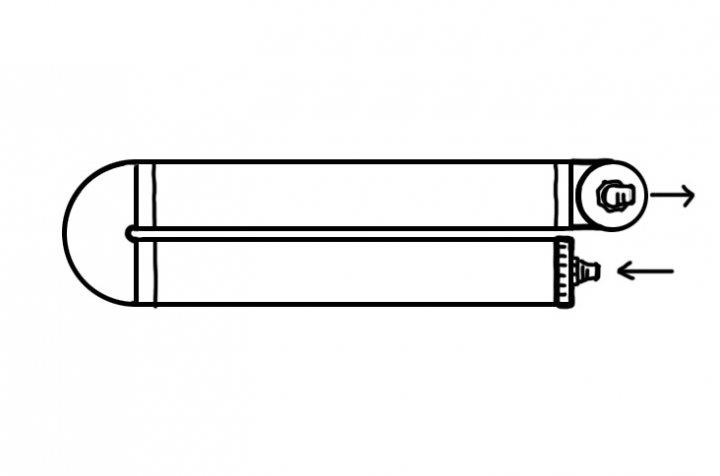

The first successful ground mounted design of the 100mm PVC section was basically two 3feet long sections joined with a U bend and a 90 bend at one end of one section going up so as not to draw sand and gravels through into the pump -even though they do no harm as the pump is all of a plastic and rubber construction. I also have a piece of 1/4"mesh folded over the outlet pipe inside the PVC section.

Here's a top-down sketch of what the older PVC section looked like:

This was still very heavy and awkward to empty when full. For this older version we also had the pump on a small separate stand. The results from this first design speak for themselves with full testing down on the Buckland River. My good friends (who had an identical one to ours after I bought them everything needed to thank them for the use of their shed while staying in Albury) used a cut off silicone gun nozzle (two of which are pictured with the pump at the top) cut down to 12mm/half inch with great success (after I had come home) as it still gave very high suction while preventing blockages.

What I see ahead is something along these lines:

The base of the PVC section as a backpack is now easy to unscrew and empty into a sluice or pan etc. What I still need to do is probably just mount the pump on a non water reactive board like plastic or perspex to either stand or kneel on when using one-handed. Should do the trick nicely when finished. No more shoving your hands into small cracks and holes risking a bit of broken glass/old rusty metal cutting you or using your mouth to suck up the mud and gravels into a hose, sometimes resulting in an unwanted mouthful.

Any comments or questions are always highly appreciated! I may have left out a bit here and there but I hopefully got the basics of it across.

Cheers guys,

Shauno.

As this had some interest over on Matt22's DIY Hand Dredge thread, I thought I would give it it's own thread to be a bit more concise on changes and idea's that may come.

The basics of this bilge pump design had come from a previous one I found many years ago and I believe there are one or two similar still around on the older US prospecting forums. However saying that, I have yet to see or find a good backpack mounted design like this. The basic parts are in the first photo -minus the actual strapping section that I still need to find for the mounting application. It can still be used on the ground as we did with the first design, but not as portable that way.

These 1" Jabsco manual bilge pumps are some serious business! Purchased from BIAS Boating and rated at 100L/min -which I feel is pretty close to real world use as it gives a squirt that goes out anywhere between 12-15feet every second or so. In the field we found that once primed it only needed a few good pumps to create tremendous suction in the PVC unit. The reason for the PVC is that on initial testing we thought of using a drum for strength so I set it up with a thick walled brewers keg (rated for high compression) and after priming and giving a few good pumps the keg just imploded and completely destroyed itself. It did this on a second try with a 10ltr (20Gallon) steel oil drum (with the clip locking lid) . This was a blessing in a way as we also realised the weight of a drum full of dirt and water was far too much to handle anyway so we then scaled it down somewhat.

The first successful ground mounted design of the 100mm PVC section was basically two 3feet long sections joined with a U bend and a 90 bend at one end of one section going up so as not to draw sand and gravels through into the pump -even though they do no harm as the pump is all of a plastic and rubber construction. I also have a piece of 1/4"mesh folded over the outlet pipe inside the PVC section.

Here's a top-down sketch of what the older PVC section looked like:

This was still very heavy and awkward to empty when full. For this older version we also had the pump on a small separate stand. The results from this first design speak for themselves with full testing down on the Buckland River. My good friends (who had an identical one to ours after I bought them everything needed to thank them for the use of their shed while staying in Albury) used a cut off silicone gun nozzle (two of which are pictured with the pump at the top) cut down to 12mm/half inch with great success (after I had come home) as it still gave very high suction while preventing blockages.

What I see ahead is something along these lines:

The base of the PVC section as a backpack is now easy to unscrew and empty into a sluice or pan etc. What I still need to do is probably just mount the pump on a non water reactive board like plastic or perspex to either stand or kneel on when using one-handed. Should do the trick nicely when finished. No more shoving your hands into small cracks and holes risking a bit of broken glass/old rusty metal cutting you or using your mouth to suck up the mud and gravels into a hose, sometimes resulting in an unwanted mouthful.

Any comments or questions are always highly appreciated! I may have left out a bit here and there but I hopefully got the basics of it across.

Cheers guys,

Shauno.