You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Update on the New, Compact Crusher

- Thread starter Ryan27

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

very nice mate I want one, do you need to open it up to remove material? or is there a screen?

The unit needs to be tipped upside down to empty, which is pretty easy as it is a light weight.G0lddigg@ said:very nice mate I want one, do you need to open it up to remove material? or is there a screen?

I caught up with Geoff Strang today for a demonstration.

I gave both the 240volt and the 18volt a run with some conglomerate I picked up at Waanyarra. It turned the conglomerate into flour in 3 to 4 seconds.

Geoff panned off the concentrates and we found ........nothing LOL

There was a good concentration of heavy!!! Black sand which is a good sign that the conglomerate may contain the good stuff.

I have collected a 20ltr bucket of this cement from the area mentioned so there is hope yet.

I designed this product for fast crushing and sampling, it is a good move up from a conventional Dolly Pot.

Once satisfactory results are achieved then I guess the decision can be made the introduce more production based crushing equipment.

Cheers Ryan

The Milwaulkee brushless grinder performed OKBen78 said:Those Milwaukee Fuel grinders are fantastic

However I would recommend the 240 volt system first. Due to R.O.I.

Love your work Ryan its top notch.

Any maintenance required on these units over time?

Is it using chain link or jaws/plates to do the crushing and how often do these need to be changed out? Are these readily obtainable if you had to do field repairs?

I note the use of wing nuts to hold main plate on, is there some sort of foam lining inside to seal this so the crusher dust doesn't escape out between the plate and the body of the unit?

With the bend in the neck of hopper for the unit will rocks get caught at the choke point of the bend, if so is it easy to clear or do you have to pull it apart?

Any maintenance required on these units over time?

Is it using chain link or jaws/plates to do the crushing and how often do these need to be changed out? Are these readily obtainable if you had to do field repairs?

I note the use of wing nuts to hold main plate on, is there some sort of foam lining inside to seal this so the crusher dust doesn't escape out between the plate and the body of the unit?

With the bend in the neck of hopper for the unit will rocks get caught at the choke point of the bend, if so is it easy to clear or do you have to pull it apart?

Hi gcause,gcause said:Love your work Ryan its top notch.

Any maintenance required on these units over time?

Is it using chain link or jaws/plates to do the crushing and how often do these need to be changed out? Are these readily obtainable if you had to do field repairs?

I note the use of wing nuts to hold main plate on, is there some sort of foam lining inside to seal this so the crusher dust doesn't escape out between the plate and the body of the unit?

With the bend in the neck of hopper for the unit will rocks get caught at the choke point of the bend, if so is it easy to clear or do you have to pull it apart?

I will answer your Q's as best as possible.

The crusher is a Rotary Impact Crusher, chain links, see photo below.

The unit does require maintenance. The rota shaft turns at 10,000 RPM's , so as you can imagine when ore is added there is a lot of friction going on.

I will be supplying spare parts for those who want to push the unit at limit ( like I will be doing )

I have run maintenance on Primary Jaw Crushers, Tertiary crushers etc. all require maintenance.

However the cost of maintenance (minimal) Vs time and volume of final concentrate ore will be rewarding.

I did think of putting a rubber membrane (gasket) to seal cover plate. However after initial testing today I feel it is not necessary.

As long as material is 25mm or even 30mm Minus fed into cranked intake there will be no plug ups.

I will be working on instruction manual / maintenance etc and Safe operation of Unit. Over the next week or so.

Geoff Strang has done a lot of business with George (Qld miners den) including some products I have made over the years.

When the Compact Crusher is Ready for the Gold Field maybe you can have a word to George, and stock one.

Any Questions I am happy to answer...

Cheers Ryan

Hi Bazz,Bazz said:Hey Ryan

This look s great, I think I'll pass on getting one of your dolly pots....

Is it too early to ask price point ???????

Thanks

Bazz

I am finalising pricing now. I think that they will Retail at around $600 dollars ( this includes 5" grinder )

I will be doing a special for Forum members as a product intro for $ 395 plus P&H

This will be very temporary !

Hopefully the product is well supported so large batches can be manufactured to keep pricing down

Cheers Ryan

Ryan,

Thank you for taking the time to answer those questions greatly appreciated.

I don't work for NQ Miners Den but can certainly have a chat to George for you. I will point him at this thread.

I will point him at this thread.

George does stock rock crushers already they are large bulky units so this would be a good complimentary item to his stock for those wanting a portable unit they could do loaming with.

Cheers,

Grant

Thank you for taking the time to answer those questions greatly appreciated.

I don't work for NQ Miners Den but can certainly have a chat to George for you.

George does stock rock crushers already they are large bulky units so this would be a good complimentary item to his stock for those wanting a portable unit they could do loaming with.

Cheers,

Grant

Hey Ryan

Mate it looks like you know your stuff in the fabrication world, very impressive!! what is the diameter of the drum, do you have a price for the unit ex the grinder????

Mate it looks like you know your stuff in the fabrication world, very impressive!! what is the diameter of the drum, do you have a price for the unit ex the grinder????

Drum is 165mm OD.rc62burke said:Hey Ryan

Mate it looks like you know your stuff in the fabrication world, very impressive!! what is the diameter of the drum, do you have a price for the unit ex the grinder????

The unit has a bracket specifically for the grinder, each grinder is different, it would have to be same brand.

Price for crusher only is $325

This is intro offer only

Hi Ryan,

Advised George to have a look at this thread. Hope it helps.

Cheers,

Grant

Advised George to have a look at this thread. Hope it helps.

Cheers,

Grant

Thanks Grantgcause said:Hi Ryan,

Advised George to have a look at this thread. Hope it helps.

Cheers,

Grant

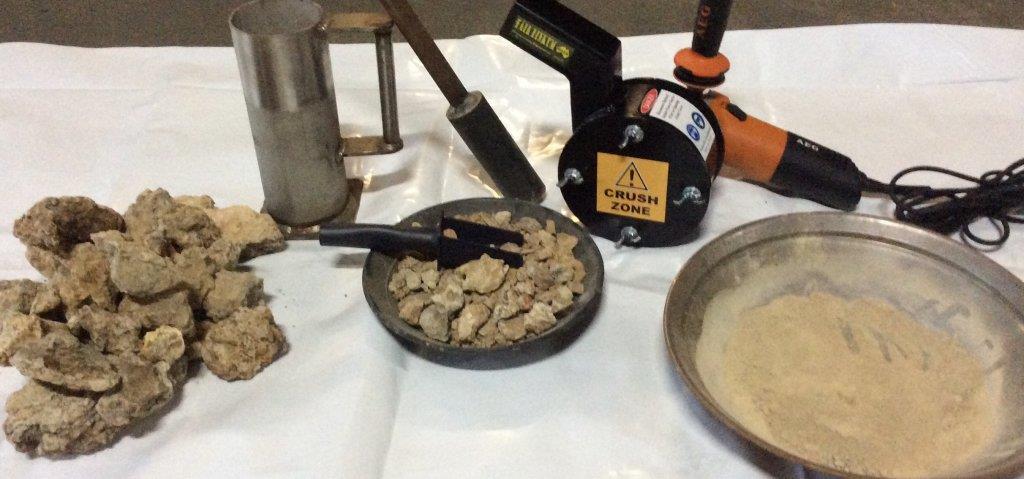

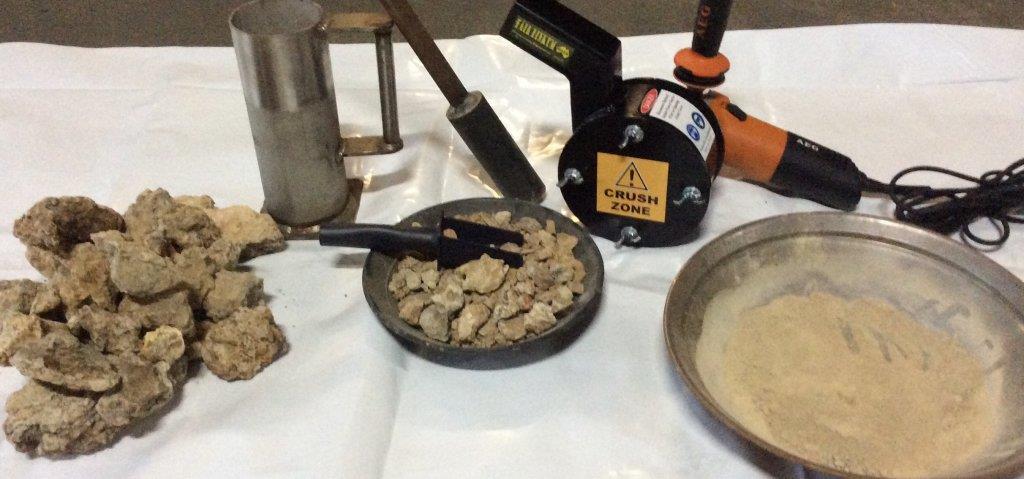

Here is a bit of an update on the portable Compact Crusher. With photos

Step 1.

I started with some suspect material I found in a very local spot at Waanyarra. It looked like the material had been carted to this area for crushing many years ago.

Step 2.

I gave the material 3 to 4 smacks in the Dolly pot to break it down to 25mm to 30mm minus.

Step 3.

I used the scoop to feed material into Compact Crusher. The scoop comes with the crusher, it's purpose is to double up as a safety guard in case the rota throws a link or bolt.

Step 4.

Tip the Compact Crusher upside down over a pan, give the grinder a short burst and empty powder into pan.

I found each scoop took approx 3 to 4 seconds to process. The Crusher could take around 3 to 4 scoops before each empty out.

This is what was left of the ancient conglomerate after 4 seconds in the Compact Crusher.

Geoff Strang from Prospecting Supplies Australia will also validate this claim.

It is a very simple and fast way to process ore samples. Now when I go detecting I will be on the lookout for any rock that may have any suspect indicators in it including hot rocks. There is now another opportunity to come home with more Gold.

Cheers Ryan

Step 1.

I started with some suspect material I found in a very local spot at Waanyarra. It looked like the material had been carted to this area for crushing many years ago.

Step 2.

I gave the material 3 to 4 smacks in the Dolly pot to break it down to 25mm to 30mm minus.

Step 3.

I used the scoop to feed material into Compact Crusher. The scoop comes with the crusher, it's purpose is to double up as a safety guard in case the rota throws a link or bolt.

Step 4.

Tip the Compact Crusher upside down over a pan, give the grinder a short burst and empty powder into pan.

I found each scoop took approx 3 to 4 seconds to process. The Crusher could take around 3 to 4 scoops before each empty out.

This is what was left of the ancient conglomerate after 4 seconds in the Compact Crusher.

Geoff Strang from Prospecting Supplies Australia will also validate this claim.

It is a very simple and fast way to process ore samples. Now when I go detecting I will be on the lookout for any rock that may have any suspect indicators in it including hot rocks. There is now another opportunity to come home with more Gold.

Cheers Ryan

Excellent quality products you churn out Ryan. It is a credit to you. Good luck with your endeavours in the future and I hope to see some photos of gold you have scored with your gear. Cheers, Rick

Thanks Rick,kemjak57 said:Excellent quality products you churn out Ryan. It is a credit to you. Good luck with your endeavours in the future and I hope to see some photos of gold you have scored with your gear. Cheers, Rick

I am working on a cheap concentrator sluice to run the powder through. I will keep you posted.

Blind_Freddie

Ron

I see "Ask Jeff Williams" just posted a you tube video with something similar but he added a pipe at the bottom with some small mesh to screen the fines and they pour out the bottom while crushing, Just thought that you might be interested in having a look as you might be keen to make the mod to your also.

https://www.youtube.com/watch?v=JBgXr1XftAU&list=UUEeEMoldn_MytOY17kYhX_g

https://www.youtube.com/watch?v=JBgXr1XftAU&list=UUEeEMoldn_MytOY17kYhX_g

Great idea,

However research and development is important.

I am still putting the Compact Crusher through testing. The little pipe and screen could be added if somebody really wanted it.

I have found the grinder gets hot after processing around 6 or so kilos of ore.

Therefore a continuous feed is not really necessary with a small sampling mill.

After 5 to 10 minutes the grinder is cool to go again.

I picked up an electric motor today for a continuous feed crusher. I have all parts to begin building.

In saying this, even the electric motors run red hot especially 240volt motors. I have opted for a better quality motor for this reason.

The Chinese motors tend to blow capacitors and the bearings don't last.

However research and development is important.

I am still putting the Compact Crusher through testing. The little pipe and screen could be added if somebody really wanted it.

I have found the grinder gets hot after processing around 6 or so kilos of ore.

Therefore a continuous feed is not really necessary with a small sampling mill.

After 5 to 10 minutes the grinder is cool to go again.

I picked up an electric motor today for a continuous feed crusher. I have all parts to begin building.

In saying this, even the electric motors run red hot especially 240volt motors. I have opted for a better quality motor for this reason.

The Chinese motors tend to blow capacitors and the bearings don't last.

Similar threads

- Replies

- 18

- Views

- 2K