Guy's in the morning when I'm up at my shed I reckon have that link to an online blade calc that been on the web pretty well since the creation of the web, now could just put fence planks up as blade and yes if the wind is strong enough they will turn but as charging a battery forget it.

Ok a quick web search found this

http://www.alton-moore.net/wind_calculations.html

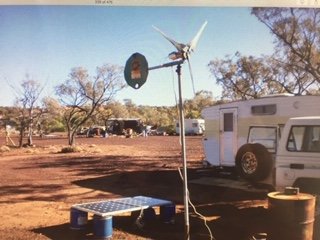

For a wind generator to work at it's full potential it needs clean air so a clear line of site for 30-50 metres and let say for a 2.4 metre blade set they do need to running at 250 rpm before cutin as far below that there just isn't enough torque with the blades.

Those multi blade sets are primarily used for water pumping as with many blades they provide the torque but as far as using them for battery charging on a serious note forget it.

now if guy's want a wind genny to charge a battery on prospecting trips a few things do need to be done.

The tower base needs to be rock solid and ramming down a couple of star pickets so only a inch or so is out of the ground only if the ground is solid so forget sandy areas as this won't work.

4 guy wires need to be put up so at 4 points 0 90 180 270 degrees where the 2 side guy wires will act as the strain when when raising and one must use what is called a gin pole where at 90 degrees to the base a pipe/ length of steel is used to alter the angle of the pull rope. Now in a pinch one can use a step ladder for the same task with one guy holding the ladder firm.

For base mounts on the guy wire again star pickets can be used and hammered in on a angle going away from the tower base.

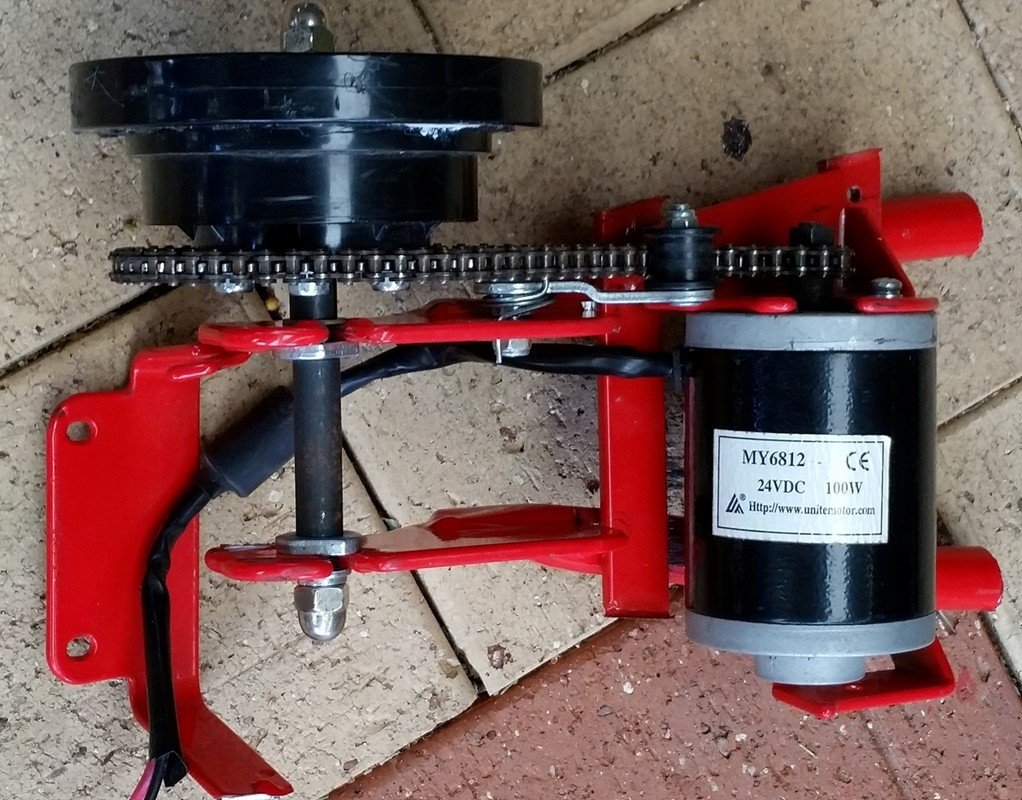

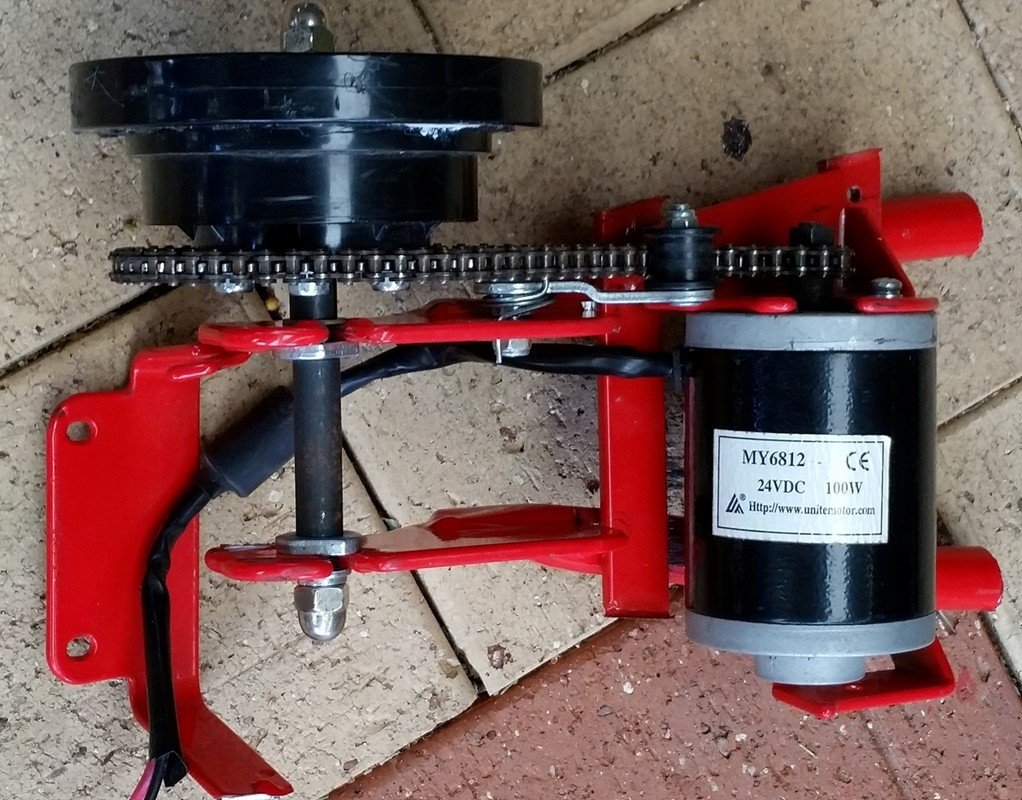

Now for alternators to charge batteries DC motors will only output about 75% of the plate rating at 1000 rpm so forget them.

The F&P washing machine motor has been used for decades and just keeps working, now there is a forum that is based around this motor and it's the backshed.com off memory. Now there is also what one calls a dual axial flux generator where 2 opposing plates hold neo magnets with the stator in the middle which is a series of coils potted in fiberglass etc, the coils can be configured for any application but be aware in gale force wind they will burn out if they go over speeding.

I have been researching and making wind generators for 2 decades and I can offer advice for guy's that want one for charging.

Cheers Bryan