Check out this PDF of alignment, there is a lot of good info here that can be applied to the Topaz Tec. Everything starts with a flat Lap, and I mean a flat! Run a steel straight edge over your laps looking at a light and see how they look, hollows will turn your life into hell, particularly when starting your journey into faceting as you don't know where the problems come from.

Pay particular attention to the quill alignment section with 2 dops and some glass, the Topaz Tec does not have an engagement pin for the index wheel so you have to line it up accurately, the quill lock is only the start as it's alignment is approximate, also when nipping the index up with the allen key, don't overtighten and don't have the top index pawl engaged, you'll bend it.

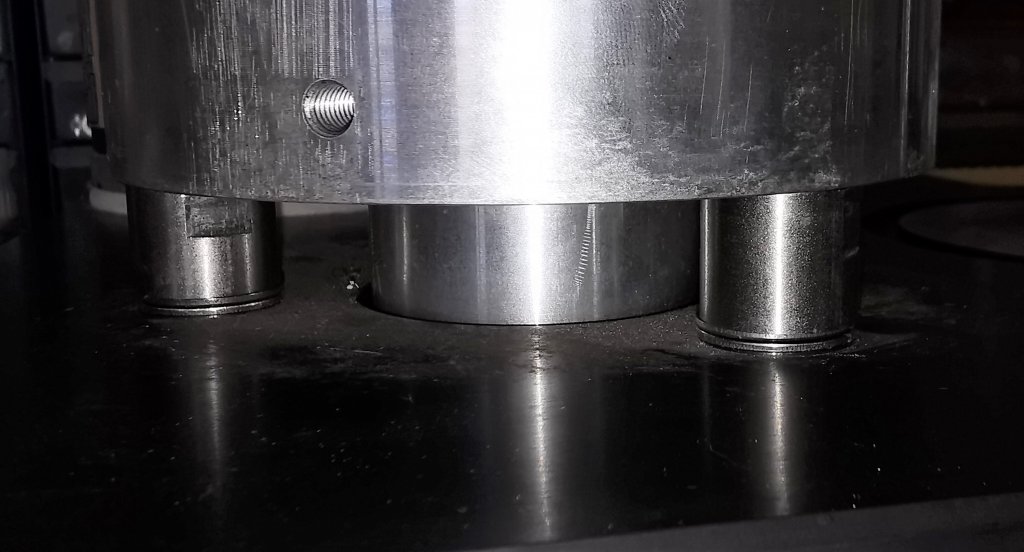

The first step is checking your spindle bearings, there should be no slop or grittyness, if there is replace them. Next is Levelling the lap, done with a spanner on the 3 little pillars under the bowl.

Under these pillars are 2 x Belleville washers which create a spring, make sure these are stacked correctly, inner to inner, outer to outer starting with the cone outer on the machine bed. When ours arrived they were wrong.

Check levels on your master lap directly above these adjusters, the three points need to be identical, then rotate the lap 1/3 and check again, then spin gently and see of the indicator bounces at all. If you rotate and the needle bounces, this indicates one of two things, lap is bent or spindle is bent provided the bearings are good.

https://www.prospectingaustralia.com/forum/doc/member-docs/10304/1621489791_faceting_machine_alignment.pdf

Now you can move on the the other parts before cutting your first stone, the machine has been eliminated, now it's you.