You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Angus mackirk boss sluice conversion to mini high banker, cheap

- Thread starter Cody1382

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Syndyne

Shaun Galman

G'day Cody1382,

I did a AM HB build myself a couple of years back. I run it with a small Tanaka TCP25 1" 2stroke pump that runs at 110Ltrs p/min. Using sixty feet (20mtrs) of marine flex hose. We normally run it around 1/2 throttle.

I wish I had of known of these forums back when I built it as I probably could've saved a few dollars on a different pump. The Tanaka is more of a top shelf, fairly expensive model at $605. There's plenty of cheaper options around.

If the AM Highbanker thread doesn't answer your questions feel free to PM me and I'll do my best to help out.

AM Highbanker thread:

https://www.prospectingaustralia.com/forum/viewtopic.php?id=902

Have a good read of these pump threads. Some great info here:

https://www.prospectingaustralia.com/forum/viewtopic.php?id=2524

https://www.prospectingaustralia.com/forum/viewtopic.php?id=837

Kindest regards,

Shauno.

I did a AM HB build myself a couple of years back. I run it with a small Tanaka TCP25 1" 2stroke pump that runs at 110Ltrs p/min. Using sixty feet (20mtrs) of marine flex hose. We normally run it around 1/2 throttle.

I wish I had of known of these forums back when I built it as I probably could've saved a few dollars on a different pump. The Tanaka is more of a top shelf, fairly expensive model at $605. There's plenty of cheaper options around.

If the AM Highbanker thread doesn't answer your questions feel free to PM me and I'll do my best to help out.

AM Highbanker thread:

https://www.prospectingaustralia.com/forum/viewtopic.php?id=902

Have a good read of these pump threads. Some great info here:

https://www.prospectingaustralia.com/forum/viewtopic.php?id=2524

https://www.prospectingaustralia.com/forum/viewtopic.php?id=837

Kindest regards,

Shauno.

angus mckirk states that the foreman sluice requires 2000 GPH of flow

i have used one for a HB and it was fine with the correct flow , however i am uprating my HB coz i like to shovel hard when i play in the dirt , and the AM sluice gets overwhelmed so i need to go to a fully home made sluice , wider and deeper with more aggressive riffles.

i run a honda WX 15 at full revs but other guys run them at half throttle with smaller HB's

i have used one for a HB and it was fine with the correct flow , however i am uprating my HB coz i like to shovel hard when i play in the dirt , and the AM sluice gets overwhelmed so i need to go to a fully home made sluice , wider and deeper with more aggressive riffles.

i run a honda WX 15 at full revs but other guys run them at half throttle with smaller HB's

Syndyne

Shaun Galman

Cheers HeadsUp!

I'll have to look into the Foreman sluice. Haven't seen the newer AM stuff or been over to the site for some time now.

Post it up if you start the new build. Love to see how you get on with it. You sound like me in the fact that we can never seem to move enough dirt in a day -even with all this equipment lol

No problems at all Cody. Glad to help.

All the best,

Shauno.

I'll have to look into the Foreman sluice. Haven't seen the newer AM stuff or been over to the site for some time now.

Post it up if you start the new build. Love to see how you get on with it. You sound like me in the fact that we can never seem to move enough dirt in a day -even with all this equipment lol

No problems at all Cody. Glad to help.

All the best,

Shauno.

Hi ya all will try and put up some pics

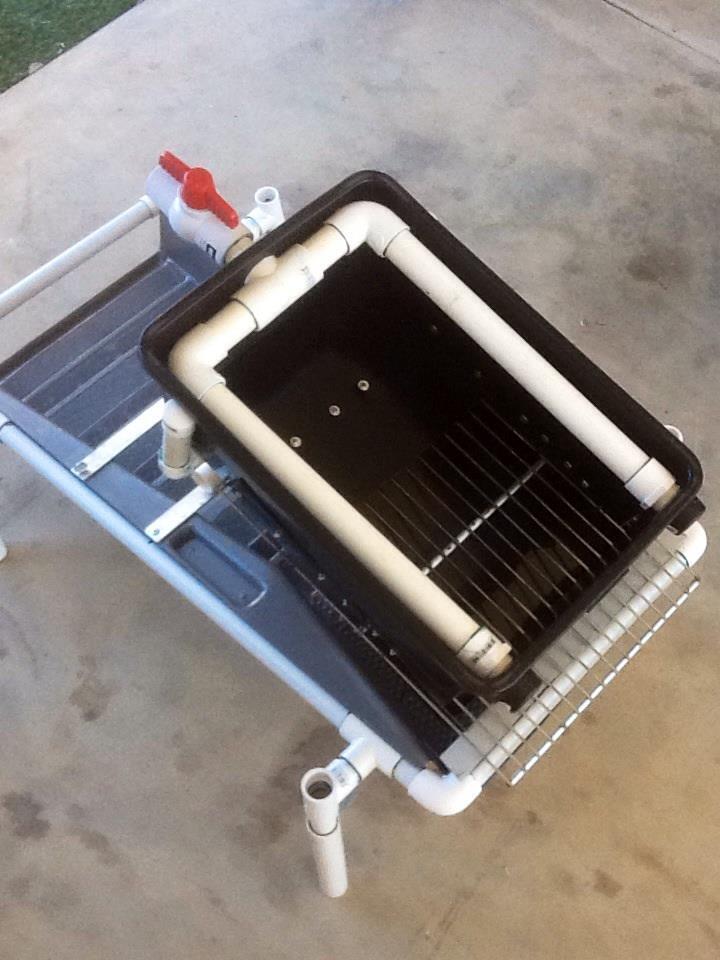

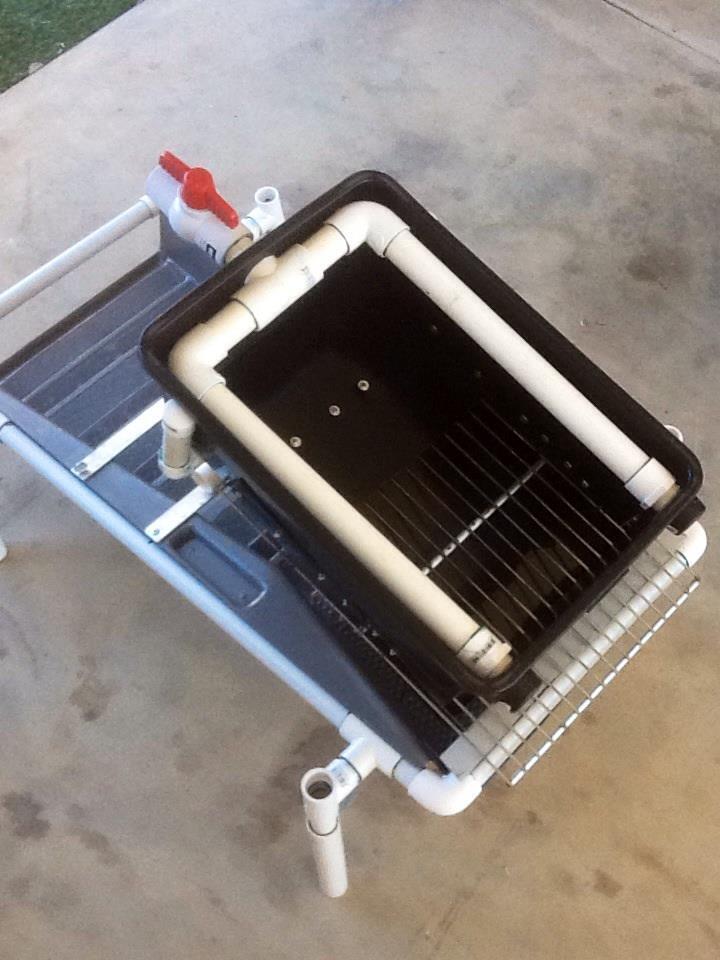

This is my budget conversion, the run down

About the unit

Grill/ classifier has 17 mm gap prob a bit big for the sluice see how it will go

Need to buy r clips for legs and hopper angle adjustments nails will suffice for the photos, there are 6 adjustments on each at 20 mm increments

Planning to run a 3000gph bilge pump or bigger as the boss needs a good flow

It's 700mm height to valve from ground, trying to keep it low, less static/ head pressure for pump, realize tailings will build up and need pushing aside

Note the frame set up to support the flared design of the boss,

Haven't cut slots into spray bars yet, still searching how many and spacing apart any suggestions?

And yes have glued them ( over eager, ) can easily be removed from hopper though

Might also put rubber flap at top end of sluice to even flow if needed as discussed by other members, that will be trial and era

Any suggestions good or bad greatly appreciated as is my first build, thanks cheers

This is my budget conversion, the run down

- 2 plastic oil trays super cheap auto $20[/*]

- PVC fittings, valve, bolt, rivots, wing nuts, washers, 2 hose clamps. Bunnings $80[/*]

- Old oven grill recyclers for $2[/*]

- 20 and 25 PVC pressure pipe FREE from the boss! Work boss, some perks for being a plumber,[/*]

- Colour bond metal for stop end in sluice free from metal manufactures[/*]

- Rubber seal between stop end and boss tray free, old car tube[/*]

About the unit

Grill/ classifier has 17 mm gap prob a bit big for the sluice see how it will go

Need to buy r clips for legs and hopper angle adjustments nails will suffice for the photos, there are 6 adjustments on each at 20 mm increments

Planning to run a 3000gph bilge pump or bigger as the boss needs a good flow

It's 700mm height to valve from ground, trying to keep it low, less static/ head pressure for pump, realize tailings will build up and need pushing aside

Note the frame set up to support the flared design of the boss,

Haven't cut slots into spray bars yet, still searching how many and spacing apart any suggestions?

And yes have glued them ( over eager, ) can easily be removed from hopper though

Might also put rubber flap at top end of sluice to even flow if needed as discussed by other members, that will be trial and era

Any suggestions good or bad greatly appreciated as is my first build, thanks cheers

Nice set up mate. Looks very light. I have a similar spray bar set up on my high banker. I have staggered holes rather slots in the pipes. One raw aims in straight down and the the other raw aims in the middle. It works well.

Thanks, yes yours is one mean set up, I guess with a petrol pump you will get a lot more pressure than a little bilge pump. Enlarging your photo I can see what you mean by the staggered spray, appreciate the suggestions, decisions decisions!

Goldtarget

(AKA OldGT)

I've used both types, slots and drilled holes. Slots for recirculated, drill holes for long line pumping. Each has its pros and cons. As you have indicated getting the pipe is not really an issue and on a bilge pump setup drilled will be fine, the slotted bars clear better but demand a higher flow. You can concentrate the flow in a much more controlled way with drilled holes. Awesome setup though I'm actually very inspired, a sluice is missing from my kit and this looks really handy.

[video=480,360]http://youtu.be/23rARnOZeFE[/video]

Hi all, sorry about that, quick run of the project at home, please any advice by the expert high bankers out there on any improvements needed will be greatly appreciated, much thanks take care and may the rains come soon,

Hi all, sorry about that, quick run of the project at home, please any advice by the expert high bankers out there on any improvements needed will be greatly appreciated, much thanks take care and may the rains come soon,

Teemore

One foot out the door

Looks OK ans seems to create a good flow (even though the sluice can take more ....

water flow seems well spread and even, need to be able to do that 'in the field'.

Dare you to run some cons through it while it's over the spa!!!!!

Cheers Tom

water flow seems well spread and even, need to be able to do that 'in the field'.

Dare you to run some cons through it while it's over the spa!!!!!

Cheers Tom

Just an update on total cost of project. I sometimes think after a new prospector learns the skill of panning they think where to from here?

The new best detectors are $6,000 plus it can be a bit daunting.

Even some small high bankers bought new are $1,000. Plus

This is a cheap unit, by no means the best but it may inspire some newbies to continue in our great hobby!

And of course there is a lot of fun and satisfaction in the build.

I have 5 kids and a mortgage so the dollars are important also

As previous discussed

Hopper, grill, PVC fittings. Plastic trays. $102

3700 gph bilge. From jag trading. $89

40 mm hose, clamps nut and tail

Fittings from midland irrigation. $59

Car battery deep cycle 60 amp

From century discounted because on

Shelf for more than 12 months $42

Electrical cable to extend wiring, joiners

And alligator clips from jaycar

Electrical. $24

Total. $316

Plus sluice. $180

Grand total. $496

The new best detectors are $6,000 plus it can be a bit daunting.

Even some small high bankers bought new are $1,000. Plus

This is a cheap unit, by no means the best but it may inspire some newbies to continue in our great hobby!

And of course there is a lot of fun and satisfaction in the build.

I have 5 kids and a mortgage so the dollars are important also

As previous discussed

Hopper, grill, PVC fittings. Plastic trays. $102

3700 gph bilge. From jag trading. $89

40 mm hose, clamps nut and tail

Fittings from midland irrigation. $59

Car battery deep cycle 60 amp

From century discounted because on

Shelf for more than 12 months $42

Electrical cable to extend wiring, joiners

And alligator clips from jaycar

Electrical. $24

Total. $316

Plus sluice. $180

Grand total. $496

- Joined

- Nov 27, 2012

- Messages

- 6,017

- Reaction score

- 1,979

Thanks for the video Bb. I haven't used the Boss before so can't really comment on the water flow, I think the best way to know for sure is a field test. Would you mind videoing this also? All and all a it's a pretty cool conversion so thanks for sharing.

Goldtarget

(AKA OldGT)

The mighty boss will find it, the proof is in the pan. I think it will continue to put a smile on your face mate, especially if that battery is the goods.

Snowy

Jason Snow

Nice video, water looks like its got a nice even flow about it

Hey Dave to answer your question

1. I didn't build the sluice, the angus mackirk boss sluice is the grey part at the bottom, it's a conversion to a highbanker

2. The advantage of this set up is I can easily run it as a high banker or a sluice if water flow is in adequate

3. The boss sluice is a high production unit and I can put a lot of material through it, I haven't seen many units this size for sale around my cost for building! Mini high bankers are really just that, mini! Takes a lot of time to process your wash.

4. They are so easy to clean out no matting needed, there gold recovery is just amazing!!!

5. And I enjoy the satisfaction of building something for a reasonable price that works,

Instead of just buying of the shelf!

Hope this goes some way to answer your questions, no need to be puzzled,

And already have found gold with more to come! Cheers

1. I didn't build the sluice, the angus mackirk boss sluice is the grey part at the bottom, it's a conversion to a highbanker

2. The advantage of this set up is I can easily run it as a high banker or a sluice if water flow is in adequate

3. The boss sluice is a high production unit and I can put a lot of material through it, I haven't seen many units this size for sale around my cost for building! Mini high bankers are really just that, mini! Takes a lot of time to process your wash.

4. They are so easy to clean out no matting needed, there gold recovery is just amazing!!!

5. And I enjoy the satisfaction of building something for a reasonable price that works,

Instead of just buying of the shelf!

Hope this goes some way to answer your questions, no need to be puzzled,

And already have found gold with more to come! Cheers

It's great you enjoyed build it, but at the total price. I would spend time finding gold rather than building the sluice. sorry just me it's a bit like fishing some people constantly change rigs so don't have line in water. You can't catch a fish with line out of water just like you don't find gold in your shed.

It does look good though & I understand what you are saying about matting, but I will point out that the mc kirk has to have a very accurate water flow & if it is not spot on they do lose gold easy. Where as a sluice with matting & riffles is a little more forgiving to water flow. This is another reason I prefer brought sluice as it is my opinion they catch more gold more often. preference I guess.

It does look good though & I understand what you are saying about matting, but I will point out that the mc kirk has to have a very accurate water flow & if it is not spot on they do lose gold easy. Where as a sluice with matting & riffles is a little more forgiving to water flow. This is another reason I prefer brought sluice as it is my opinion they catch more gold more often. preference I guess.

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 39

- Views

- 15K