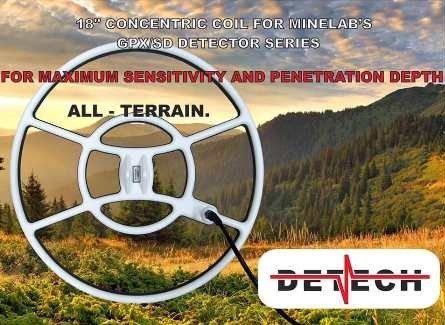

This coil doesn't have it's own thread, so thought I better start one.

A short session to report on the Detech 18" CC. Disclaimer - no I didn't find gold, but learnt a few things I'd like to share.

What I wanted to do is just swing it around, and get some more time on it - unfortunately I only had a couple hours to spare, but better that than nothing. No point doing comparison testing against other coils before knowing how it performs, and what likely settings can be used in different areas.

The spot I took it to was the Small Gold Patch that is in some of my YouTube videos. This has since been flogged with the Zed, SDC and GPX with a variety of coils. The reason I wanted to try it here was 1) this spot is pretty worked out, and 2) It is quite mineralized. A spiral/flat mono can only be used in smooth timings here. Regular monos can also be a pain but a larger mono such as a Minelab 18" is almost workable but a few tweaks are necessary. So I wasn't too sure what to expect with the Detech Concentric.

I switched on the 5000 with my normal settings but switched the front panel to Normal and DD. After ground balancing, the threshold was very stable, a welcome change from using big monos on a windy day! As I started to detect, I was on the edge of my seat waiting for the expected ground noises to come in. But they didn't. I even threw my test nugget on the ground a few times to make sure all was okay. I wasn't expecting to find much but I got a couple small bits of iron trash, most likely ignored by smooth timings on the GPX.

As I detected I was mucking around with Gain and Motion settings just sort of auditioning a few things, so I did hear a few ground noises. These were easily identified by using common techniques, i.e. comparing signals with sweep speed, ground balancing around the response area etc. I still checked a few to be sure. One which sounded a little sharper, and was still there even after re-balancing ended up being a .22 lead. "Wow, how is that still here?" was my first thought. I decided to put it back in the hole to have a play with some settings. With DD on the coil switch, I got a sharper response than in Mono. Switching the timing to Sens Extra sharpened up the response again. In DD, the coil works as a Concentric so the response is like using a smaller mono, very sharp and "tight". Imagine an 8" mono sitting inside a 18". I found that pin-pointing on a shallow target is on the outside of the inner ring (winding).

With targets virtually non-existent on the patch proper, I started working the fringe area to try and dig something. On the edge of a connecting track I got a nice sweet signal, that I expected to be a fairly shallow bullet. Before digging, I tried Mono, and the target was lost in the sudden increase in ground signal. I flicked into Enhance and I could hear it now, but the response was very faint. Back to DD and Normal and the signal was really clear and sharp. Into Sens Extra and it was sharper again, so I was pretty excited at this point. I was even more excited when it was still in the hole after two good digs, and all this crunchy wash was coming out of the hole! I thought for sure I pinged one of the right colour. When I got it in my hand it even felt good, heavy and hackly, but unfortunately it was lead.

Other general observations:

- It handled EMI like a champ, very stable

- Very light for its size

- I really liked having the option of switching between Mono and DD for different performance characteristics

- It's neither mono, nor DD, probably closer to a DD, but it can be a big mono or a bit of a hybird depending on your settings.

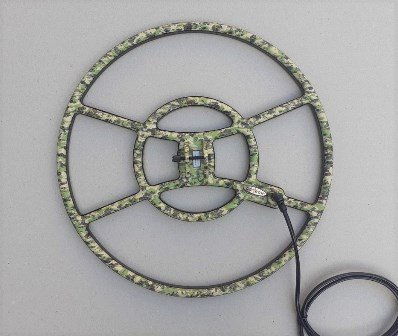

Thanks 10fp for letting me use your coil while I waited for more stock to arrive. Your closed skid is here now as well. Here's what it looks like fitted

All 18" Concentric coils supplied now include the black fitted/open skid, as well as the white closed skid. This is not a flat bottom skid, bit still prevents sticks and vegetation from getting caught in the spokes.

A short session to report on the Detech 18" CC. Disclaimer - no I didn't find gold, but learnt a few things I'd like to share.

What I wanted to do is just swing it around, and get some more time on it - unfortunately I only had a couple hours to spare, but better that than nothing. No point doing comparison testing against other coils before knowing how it performs, and what likely settings can be used in different areas.

The spot I took it to was the Small Gold Patch that is in some of my YouTube videos. This has since been flogged with the Zed, SDC and GPX with a variety of coils. The reason I wanted to try it here was 1) this spot is pretty worked out, and 2) It is quite mineralized. A spiral/flat mono can only be used in smooth timings here. Regular monos can also be a pain but a larger mono such as a Minelab 18" is almost workable but a few tweaks are necessary. So I wasn't too sure what to expect with the Detech Concentric.

I switched on the 5000 with my normal settings but switched the front panel to Normal and DD. After ground balancing, the threshold was very stable, a welcome change from using big monos on a windy day! As I started to detect, I was on the edge of my seat waiting for the expected ground noises to come in. But they didn't. I even threw my test nugget on the ground a few times to make sure all was okay. I wasn't expecting to find much but I got a couple small bits of iron trash, most likely ignored by smooth timings on the GPX.

As I detected I was mucking around with Gain and Motion settings just sort of auditioning a few things, so I did hear a few ground noises. These were easily identified by using common techniques, i.e. comparing signals with sweep speed, ground balancing around the response area etc. I still checked a few to be sure. One which sounded a little sharper, and was still there even after re-balancing ended up being a .22 lead. "Wow, how is that still here?" was my first thought. I decided to put it back in the hole to have a play with some settings. With DD on the coil switch, I got a sharper response than in Mono. Switching the timing to Sens Extra sharpened up the response again. In DD, the coil works as a Concentric so the response is like using a smaller mono, very sharp and "tight". Imagine an 8" mono sitting inside a 18". I found that pin-pointing on a shallow target is on the outside of the inner ring (winding).

With targets virtually non-existent on the patch proper, I started working the fringe area to try and dig something. On the edge of a connecting track I got a nice sweet signal, that I expected to be a fairly shallow bullet. Before digging, I tried Mono, and the target was lost in the sudden increase in ground signal. I flicked into Enhance and I could hear it now, but the response was very faint. Back to DD and Normal and the signal was really clear and sharp. Into Sens Extra and it was sharper again, so I was pretty excited at this point. I was even more excited when it was still in the hole after two good digs, and all this crunchy wash was coming out of the hole! I thought for sure I pinged one of the right colour. When I got it in my hand it even felt good, heavy and hackly, but unfortunately it was lead.

Other general observations:

- It handled EMI like a champ, very stable

- Very light for its size

- I really liked having the option of switching between Mono and DD for different performance characteristics

- It's neither mono, nor DD, probably closer to a DD, but it can be a big mono or a bit of a hybird depending on your settings.

Thanks 10fp for letting me use your coil while I waited for more stock to arrive. Your closed skid is here now as well. Here's what it looks like fitted

All 18" Concentric coils supplied now include the black fitted/open skid, as well as the white closed skid. This is not a flat bottom skid, bit still prevents sticks and vegetation from getting caught in the spokes.